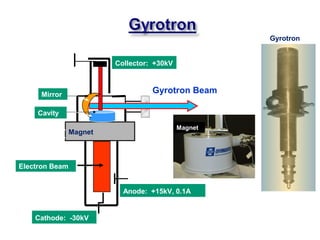

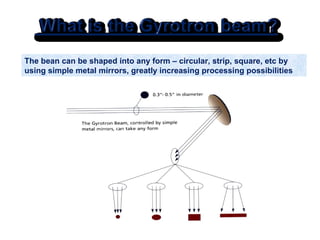

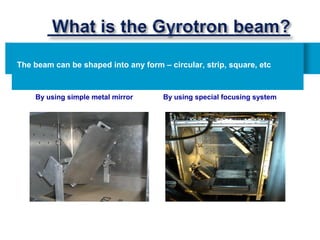

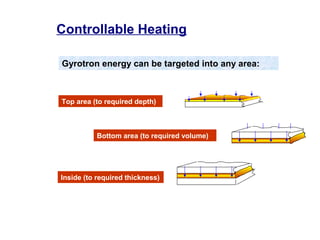

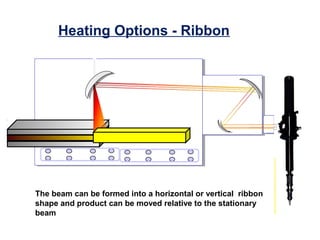

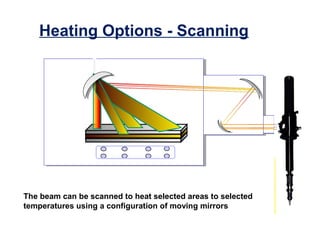

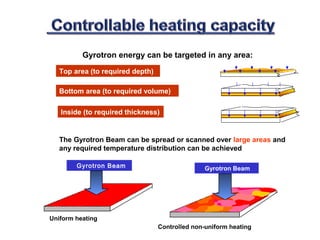

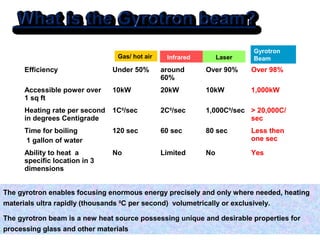

Gyrotron Technology is a Delaware corporation founded in 1998 that develops and licenses industrial microwave technologies. It has two business areas: 1) developing technologies for glass, semiconductors, solar, and plastics industries, and 2) manufacturing and selling capital equipment for gyrotron processes and manufacturing laminated glass and solar modules. Gyrotron Technology holds patents and has niche markets in several industries. It uses gyrotron beams, which are electron beams that can be shaped and targeted precisely using mirrors and focusing systems to heat materials rapidly and in a controlled manner for various industrial applications.