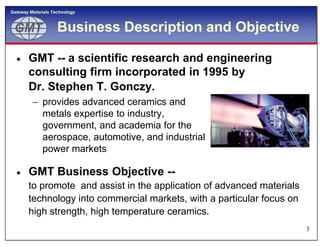

Gateway Materials Technology (GMT) is a scientific consulting firm that provides expertise in advanced ceramics and metals to industry, government, and academia. GMT's objective is to promote the application of advanced materials technology into commercial markets, with a focus on high-strength, high-temperature ceramics. GMT offers research and development services for ceramic applications, technology consulting, and program development in advanced materials. Current projects include developing test standards for ceramic matrix composites to support the aerospace, automotive, and industrial industries.

![GMTGMT

Gateway Materials Technology

Stephen T. Gonczy

President and Research Director

PhD Materials Science, Northwestern University;

BS Mechanical Engineering, Marquette University

35+ years of industrial research experience

20 years consulting (GMT). 17 years corporate (Honeywell/AlliedSignal),

70+ patents, technical articles, and test standards in ceramics,

composites, coatings, metals, and testing.

4

Adjunct Professor in ceramic engineering at Illinois Institute of Technology.

Extensive contacts in the advanced ceramics community -- industry, government,

academia.

30+ year career in US Army [Active and Reserve -- Brigadier General (Ret)] --

DoD acquisition and logistics – policy, methods, and programs with DoD security

clearance.

Fellow of ASTM (1999) and R&D 100 New Product Award (1994).

Professional training in federal contracting, technology transfer, and program

management.](https://image.slidesharecdn.com/fc8f2533-7e89-45ba-b3df-cb1710ce39a0-161002023342/85/GMT-Story16-3-320.jpg)