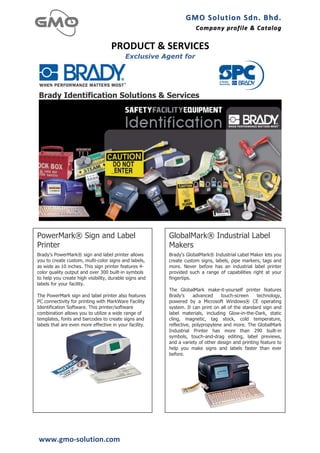

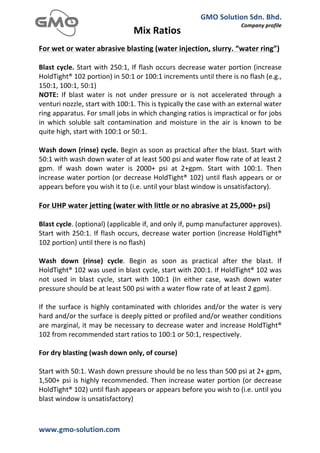

GMO Solution Sdn. Bhd., established on July 29, 2005, in Johor Bahru, Malaysia, specializes in the trading and retailing of safety, identification, and spill containment products across various sectors, including oil and gas and petrochemicals. The company focuses on high-quality service and products to meet customer specifications efficiently while maintaining compliance with safety regulations. It provides a range of equipment, including printers, labels, lockout devices, and absorbents, aimed at enhancing workplace safety and environmental protection.