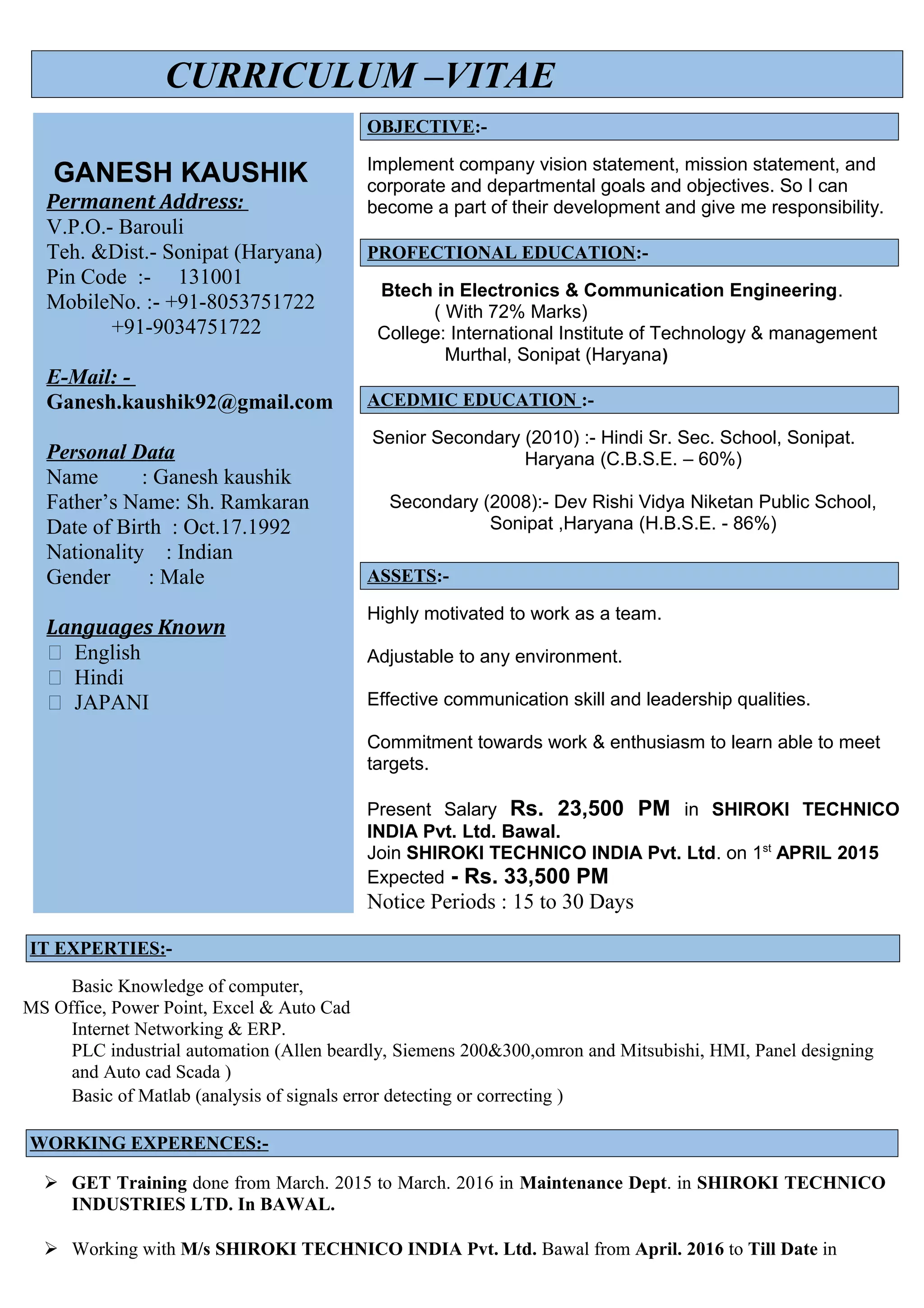

The document is a curriculum vitae for an individual with experience in industrial automation, maintenance, and engineering. It summarizes their educational background in electronics and communication engineering, work experience maintaining machines and equipment for an automotive parts manufacturer over the past 5 years, and responsibilities including programming PLCs and HMIs, maintaining various industrial systems, and providing training. Their objective is to take on more responsibility and help their current employer achieve their goals.