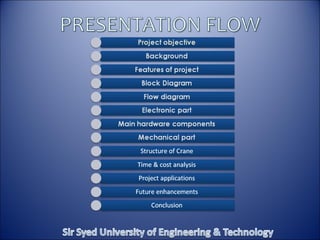

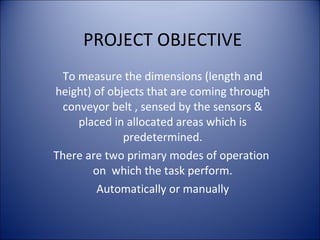

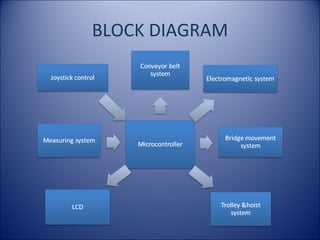

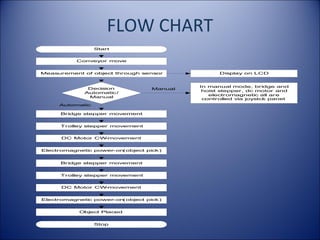

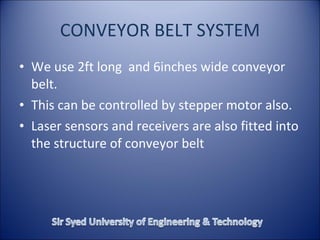

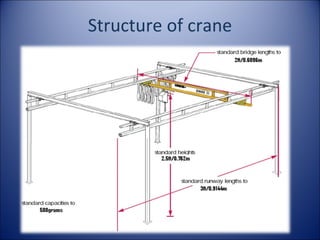

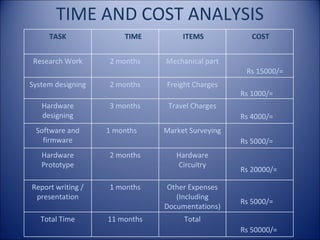

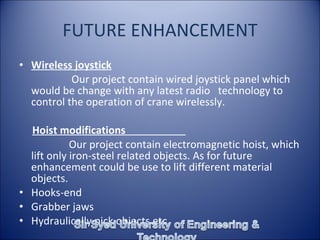

This document presents a final year project on an overhead bridge electromagnetic crane. A group of six students designed and developed the crane to automatically measure and sort objects on a conveyor belt based on their length and height. The crane uses sensors to detect objects and an AT89C52 microcontroller to control stepper motors, a DC motor, and an electromagnet to manipulate the objects. The project aims to automate material handling for industries like shipping, steel mills, and petroleum refineries. The presentation outlines the objectives, components, design, applications, and conclusions of the overhead bridge electromagnetic crane project.