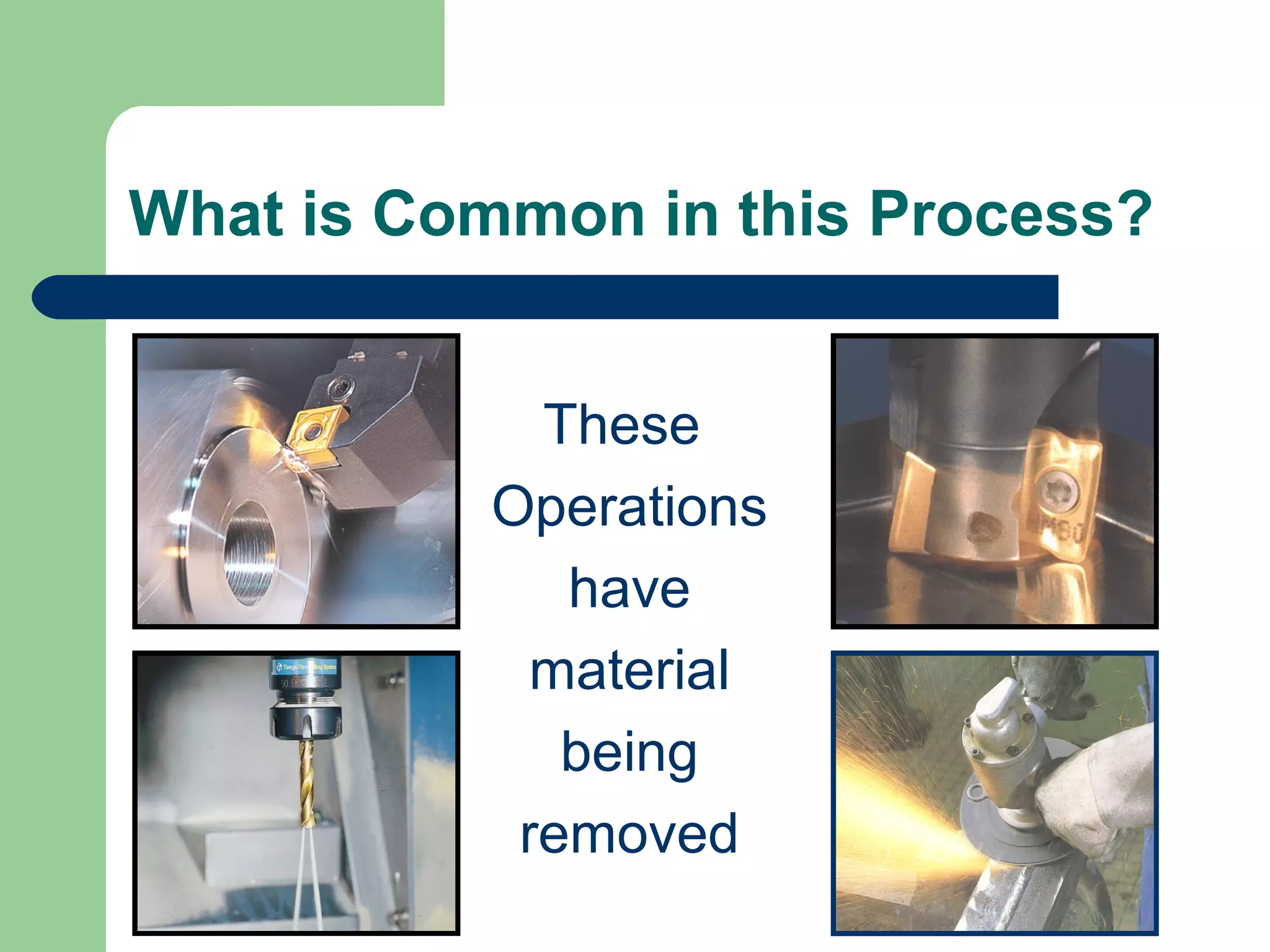

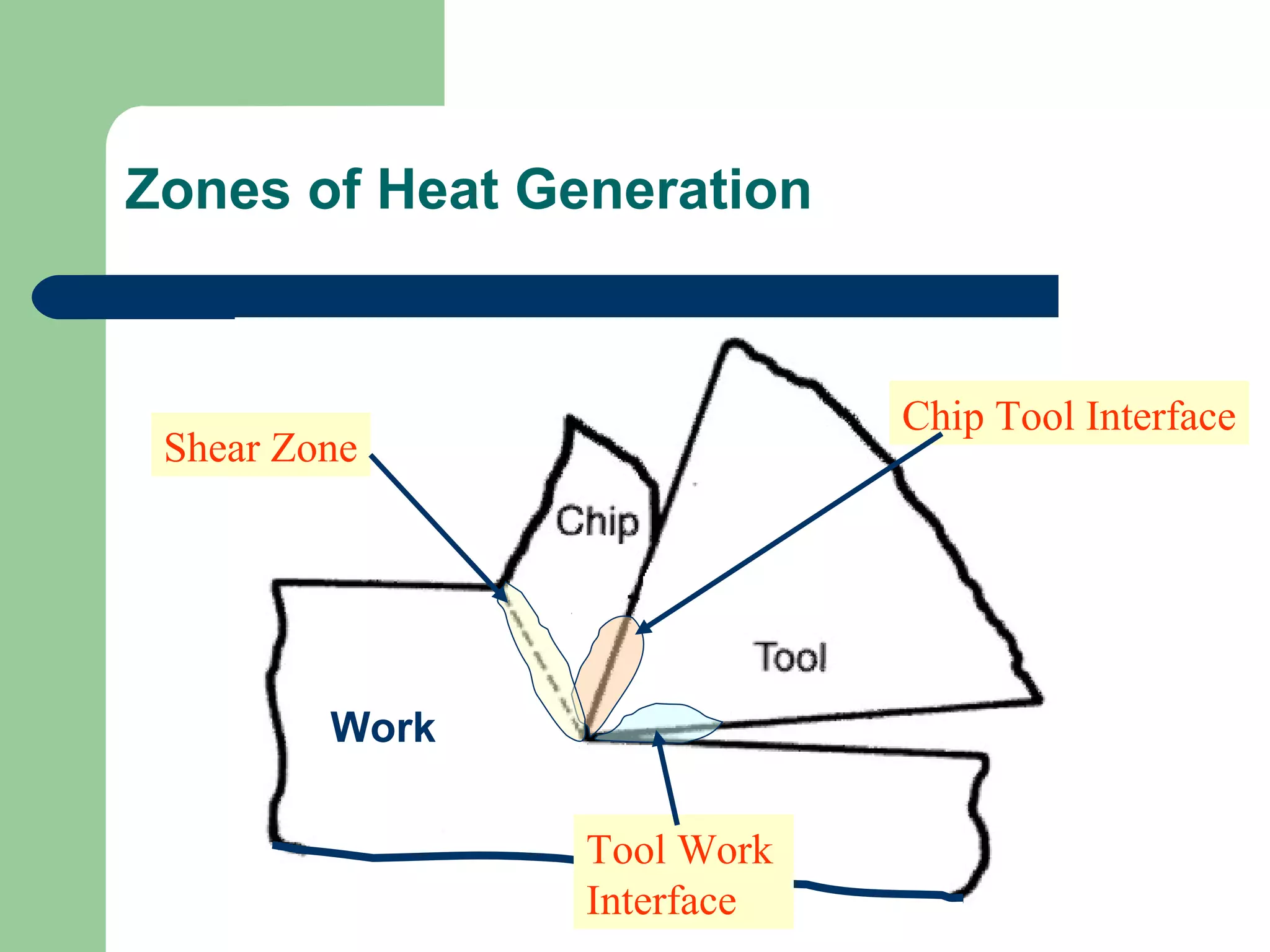

This document discusses fundamentals of cutting processes. It explains that knives are used to cut apples because they are harder and sharper than the apple, while tungsten carbide or diamond tools are used to cut harder metals like steel. It also discusses common machining operations like turning, milling and drilling which remove material. These operations require setting the depth of cut, feed rate and cutting speed. The document classifies machine tools and describes zones of heat generation and dissipation during cutting. It discusses tool wear and factors considered in rating machinability like tool life, forces, surface finish and material removal rate.