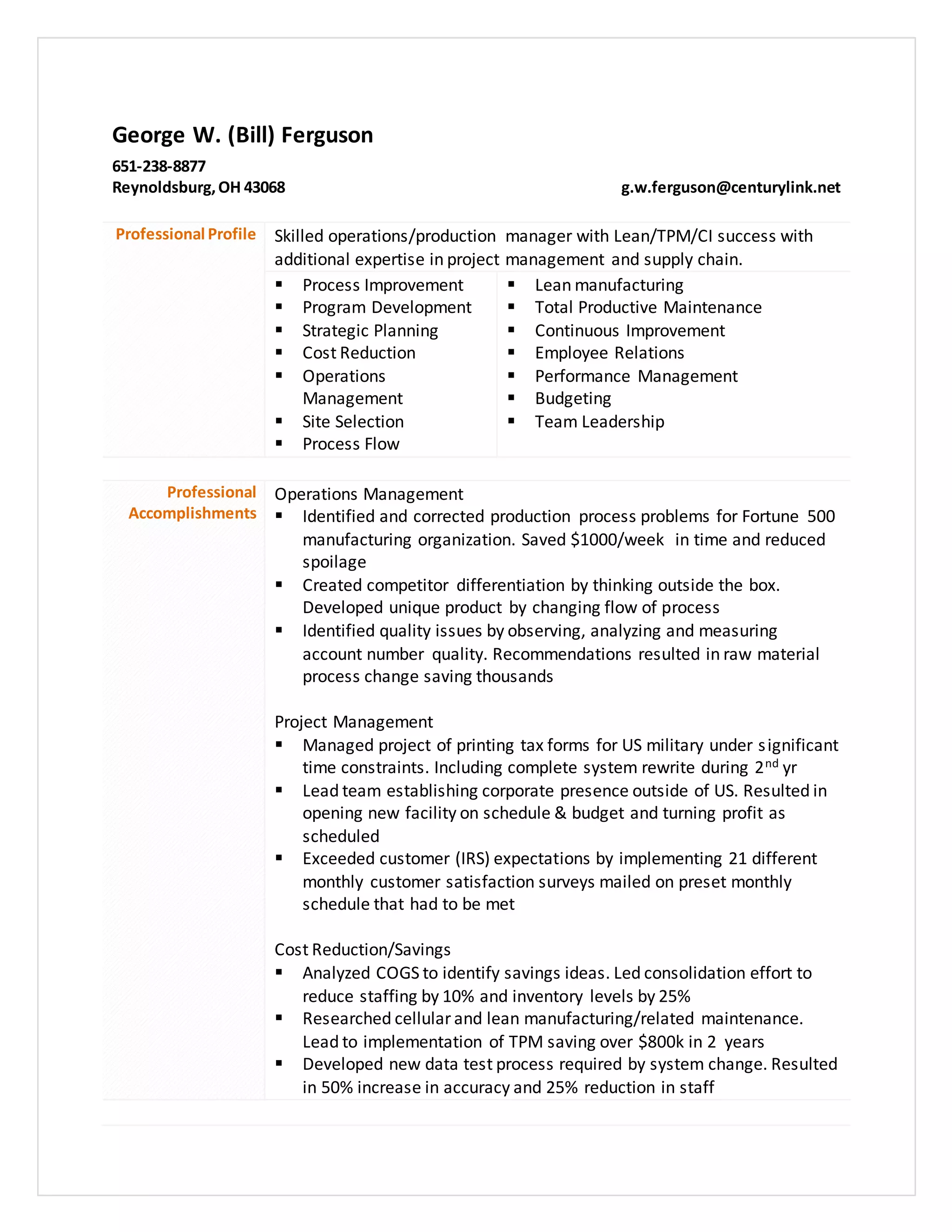

George Ferguson is an experienced operations and project manager with expertise in process improvement, Lean manufacturing, and cost reduction. He has over 15 years of experience leading operations, strategic planning, and project management. Ferguson's background includes roles as an Operations Manager, Vice President of Operations, Senior Project Manager, and business owner. He holds a BS in Business Administration from the University of Phoenix.