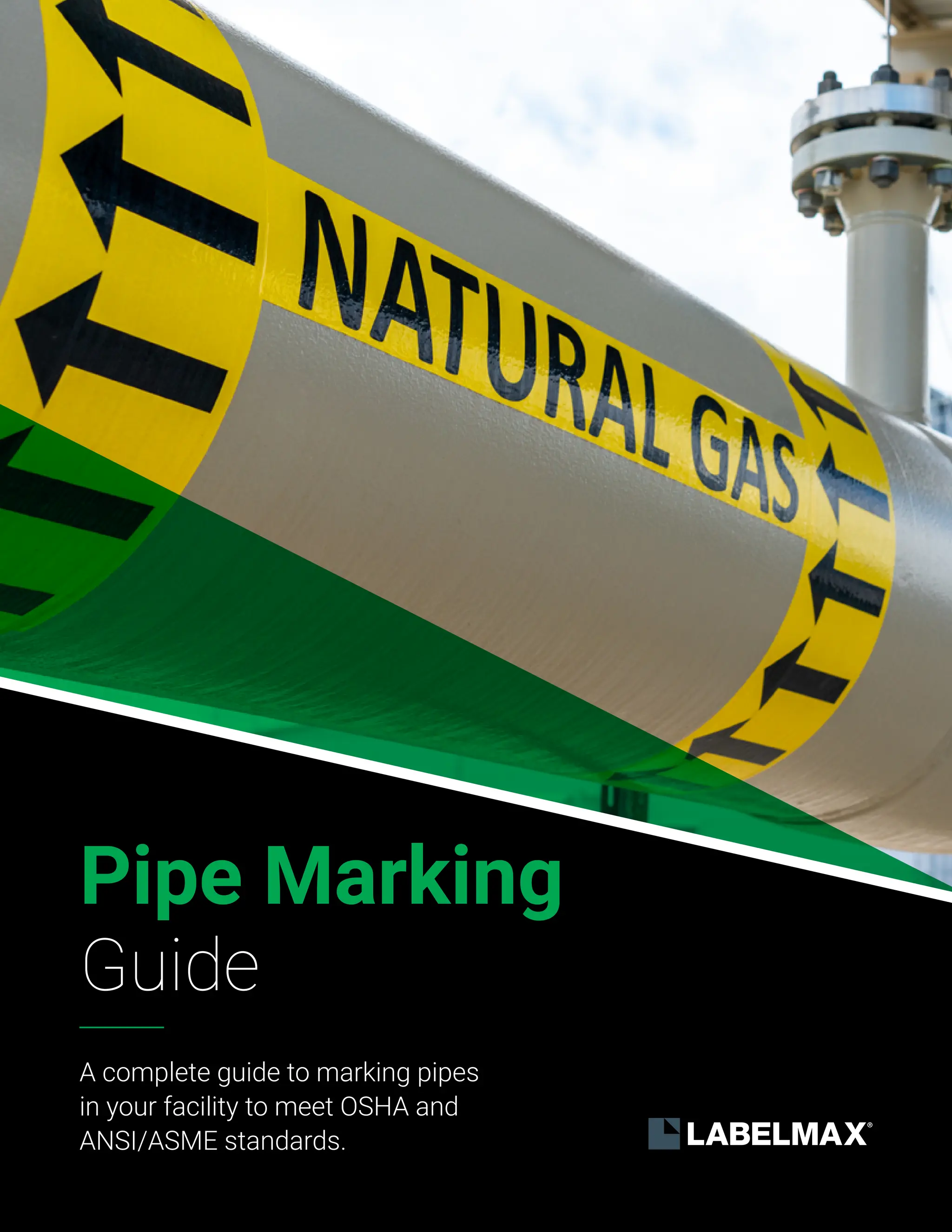

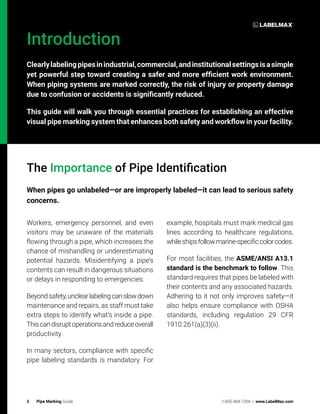

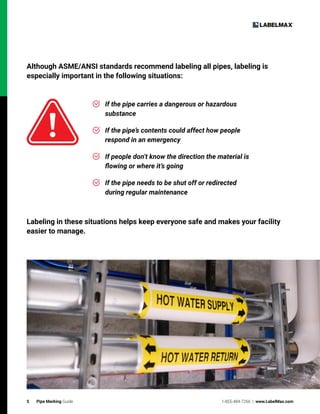

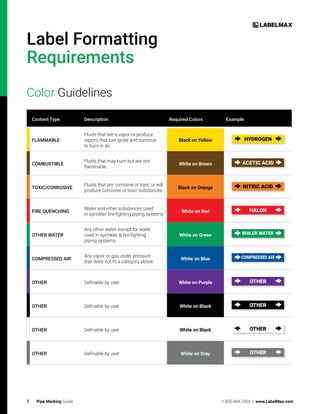

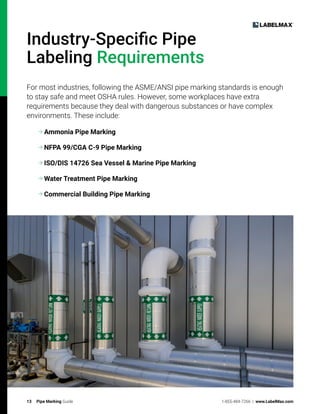

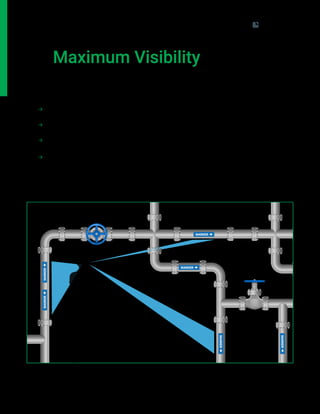

This free guide explains everything you need to know about pipe marking and labeling for workplace compliance. It outlines OSHA and ANSI standards, showing how proper pipe identification improves safety, reduces accidents, and keeps facilities running smoothly. Inside, you’ll find clear guidance on color codes, size requirements, arrow usage, and placement so that pipes are easy to identify at a glance. By following these standards, organizations can minimize confusion, improve response times, and create safer, more efficient environments for employees and visitors. Whether you manage a manufacturing plant, warehouse, or commercial facility, this guide provides practical steps to help you meet regulatory requirements and build a more organized workplace. Developed by LabelMax, it’s designed to be a go-to resource for anyone responsible for pipe marking and labeling in industrial or commercial settings.