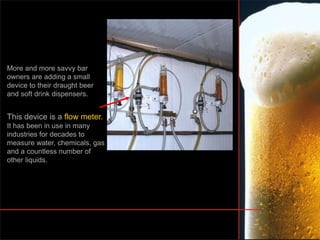

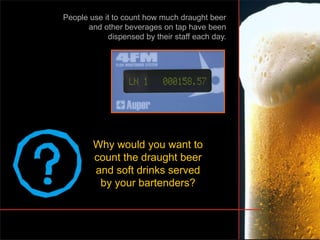

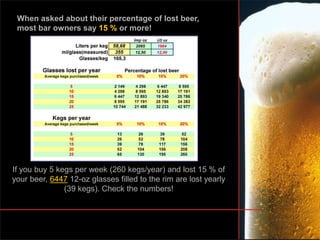

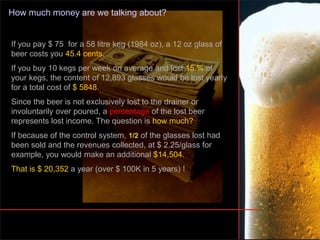

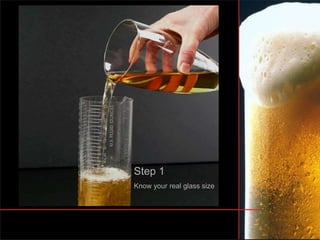

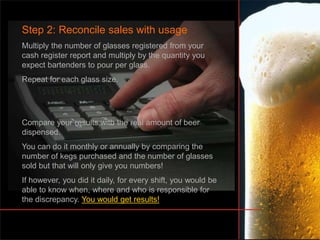

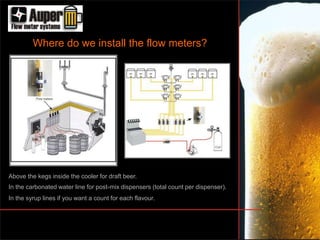

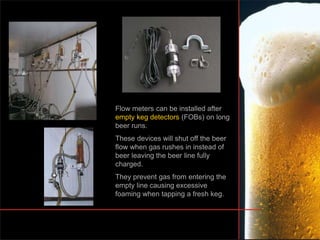

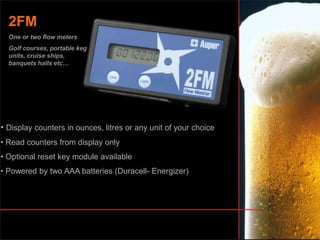

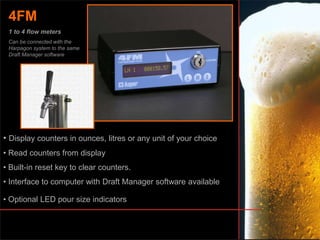

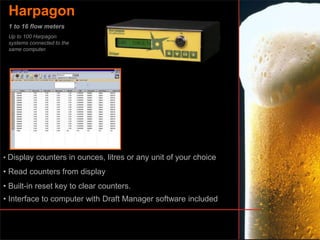

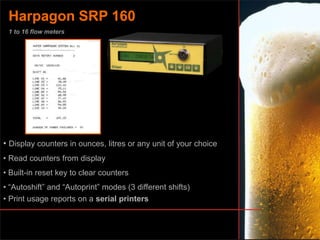

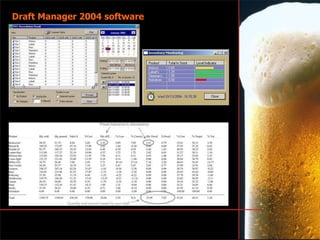

This PowerPoint presentation discusses flow meter systems for measuring draft beer and beverage dispensers. It explains that flow meters can help bar and restaurant owners track how much beer is being poured from kegs to identify losses from overpouring, waste, or theft. The presentation outlines a simple method to monitor beer usage by measuring glass sizes, tracking sales records, and reconciling the numbers with keg purchases. It then describes various flow meter models that can interface with software to monitor dispenser usage automatically and generate reports to improve portion control and profits.