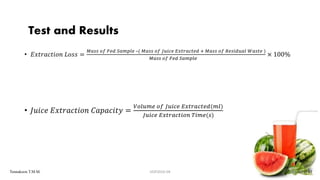

This document describes the design and testing of a watermelon juice extracting machine. A group of engineering students aimed to design a portable, low-cost machine that removes seeds and rind efficiently. They developed conceptual designs, created 3D models, and tested prototypes. Testing showed the prototype had higher juice yields, extraction efficiencies, and capacities than manual extraction, while reducing extraction losses. Future work includes modifying blade designs and completing the machine to maximize efficiency for small businesses.