The document describes the commissioning of a Codel Tunnel Craft 3 air quality monitor. The device measures carbon monoxide, nitric oxide, and visibility in tunnels. It was taken out of service from the Jack Lynch Tunnel and re-commissioned by wiring and calibrating it. Testing showed good correlation between the Codel sensor and a separate carbon monoxide probe, proving the sensor was accurately re-commissioned and ready for reinstallation.

![8 | P a g e

1.1 Background

Codel International Ltd is a UK company based in Bakewell, Derbyshire. The company

specialises in the design and manufacture of high-technology instrumentation for the

monitoring of combustion processed and atmospheric pollutant emissions. The Tunnel

Craft 3 Air Quality Monitor (AQM) is the industry proven tunnel atmosphere sensor [1].

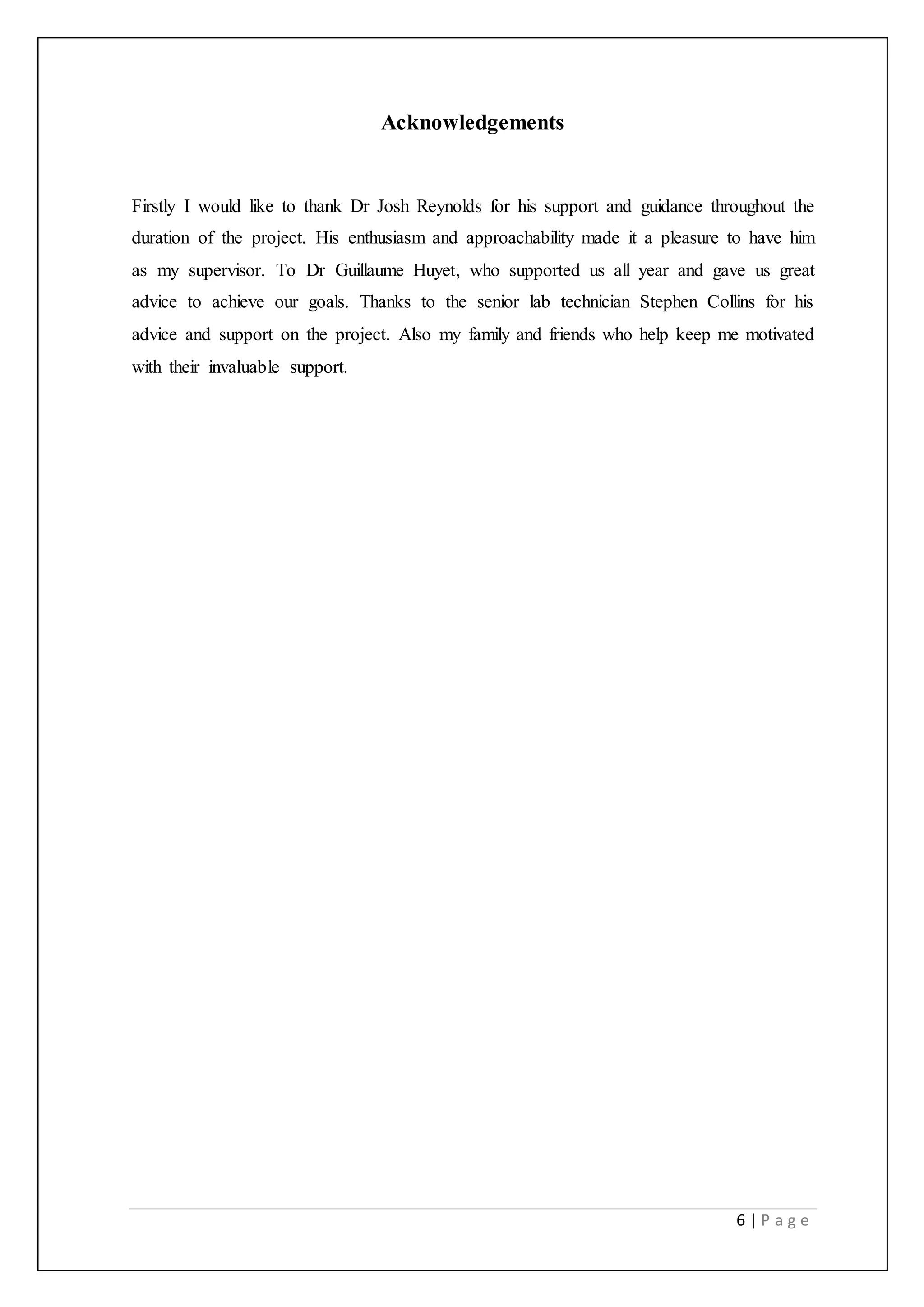

The device is a single compact sensor which can measure CO, NO and visibility. It consist

of a transceiver that projects visible and infrared beams to a reflector mounted 3 m away.

The reflector reflects the light back to the transceiver and the specific absorption is

measured to determine the visibility coefficient, carbon monoxide and nitric oxide

concentration within the path of the beams.

In the past 15 years Codel tunnel sensors have been used in more than 400 road and rail

tunnels around the world. Some well-known destinations include Eurotunnel France, Lane

Cove tunnel in Australia and SMART tunnel in Malaysia. Codel is without doubt the world

leader in tunnel atmosphere monitoring [1].

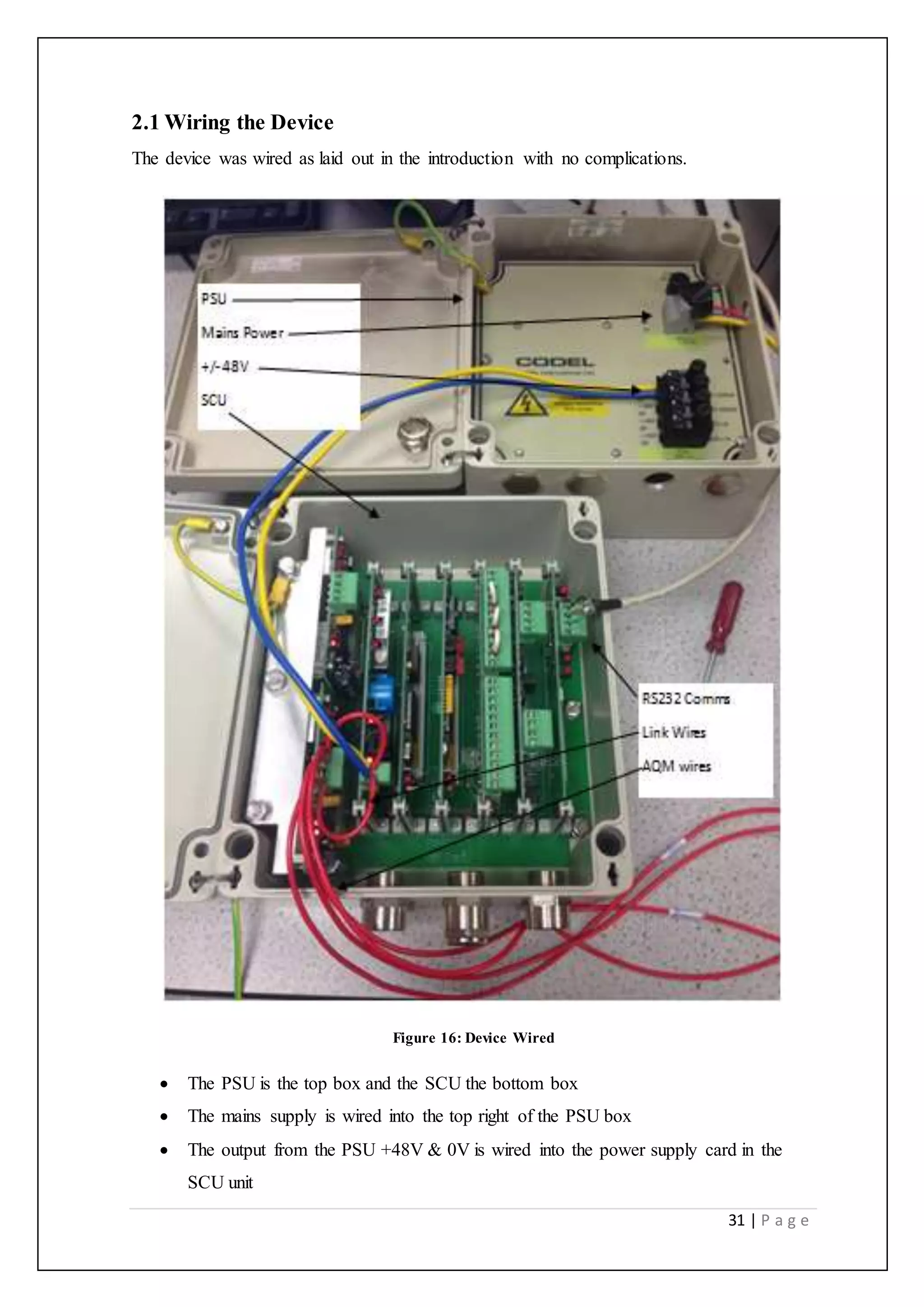

This project deals with the commissioning and testing of a Codel Tunnel Craft 3 air quality

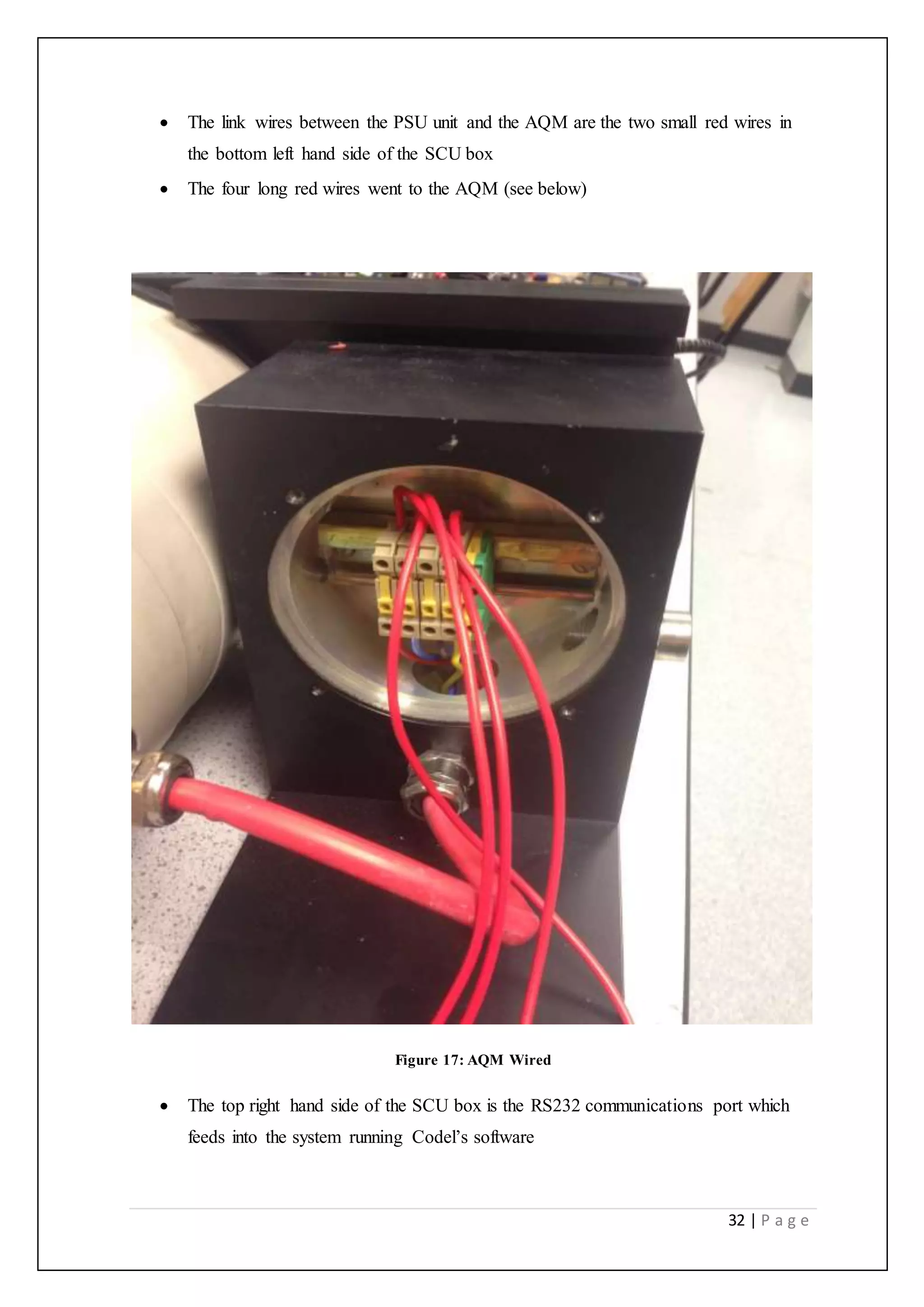

monitor. The instrument was up to quite recently deployed in the Jack Lynch Tunnel in

Cork and the initial objective is to get the equipment back to operational status. Further

requirements include calibrating the device and to critically compare it with other available

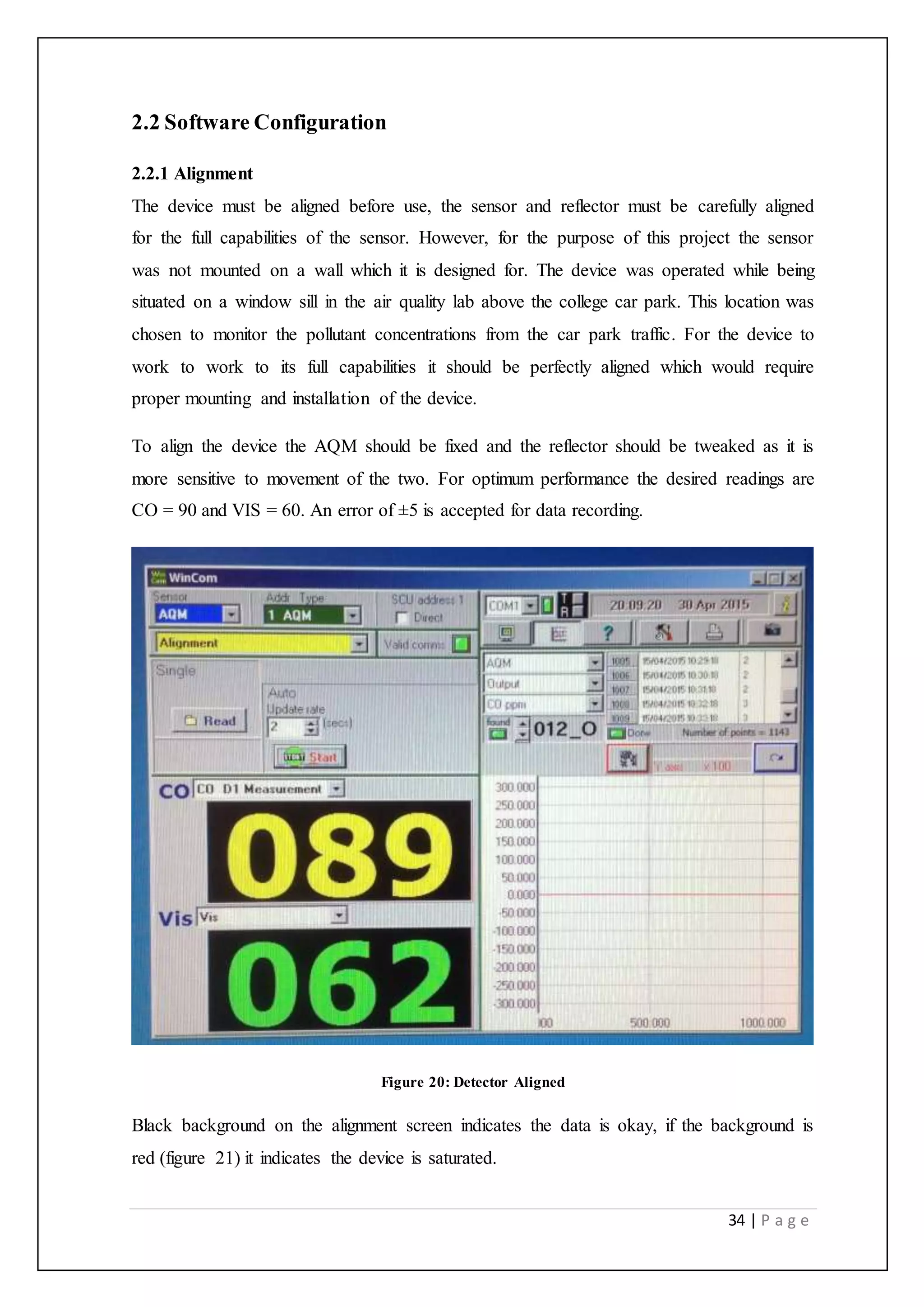

tunnel gas detectors.

1.2 Gas DetectionMethods

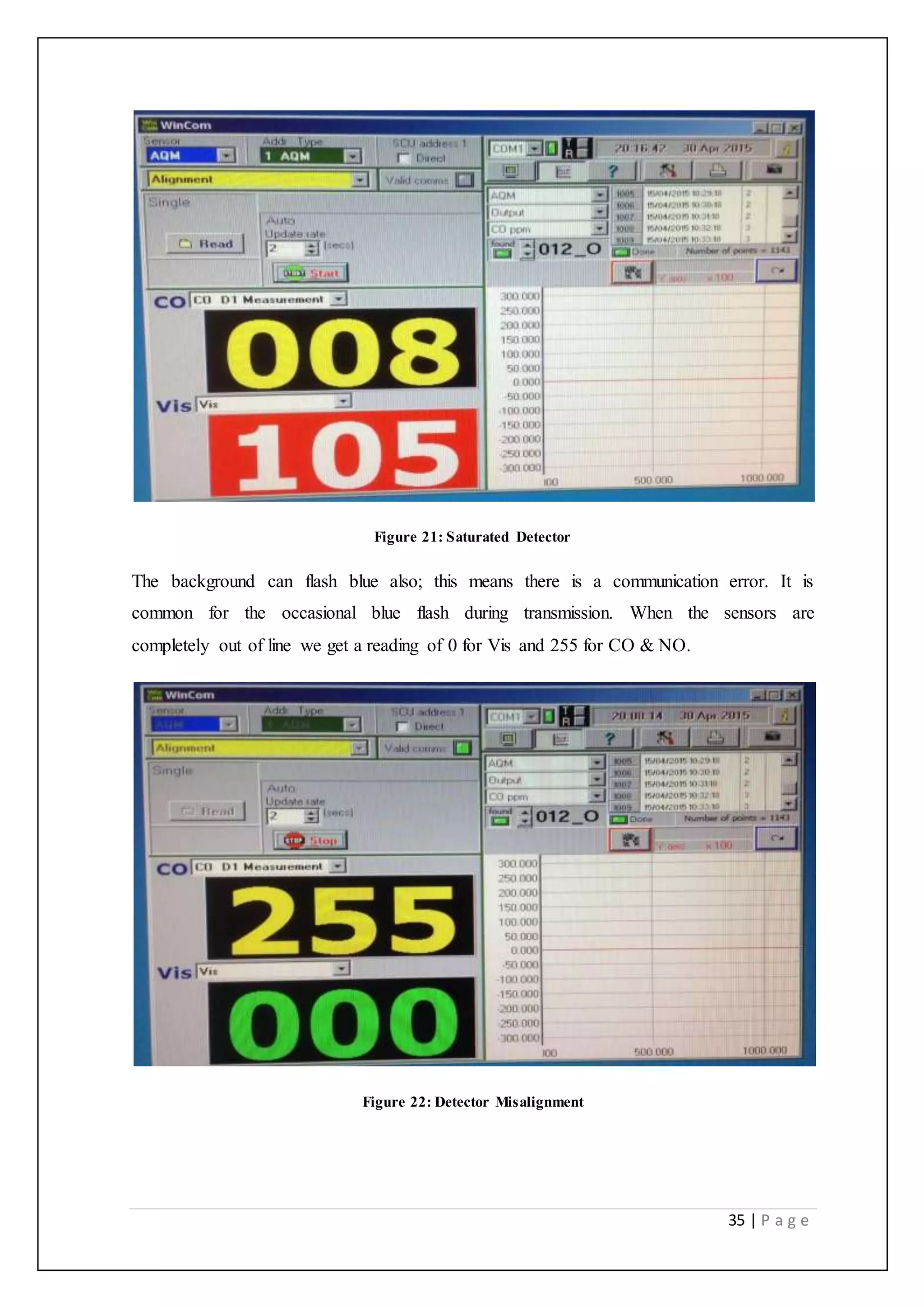

As technology has evolved so have the methods for detecting gas concentrations. The first

carbon monoxide detector was a simple white pad which would get stained if CO was

present. Newer models have alarms, flashing lights and can be programmed to go on/off

once a certain concentration has been present. Gas detectors can be portable or fixed, fixed

detectors can usually monitor more than one gas at a time. They can be classified

according to the following operation mechanisms:

1.2.1 Electrochemical

These detectors have a porous membrane which the gas will diffuse through to an

electrode. Here the gas will be chemically oxidized or reduced. The concentration of gas](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-9-2048.jpg)

![9 | P a g e

present relates to the current produced here [2]. The manufacture can alter the barrier to

detect certain gas concentration ranges. The physical barrier makes the device stable and

reliable with low maintenance. However the life span is 1-2 years due to corrosive

elements [3]. These detectors are widely used in industry such as gas turbines, chemical

plants etc.

1.2.2 Infrared

Infrared sensors work by the principle of specific absorption at certain wavelengths. They

use radiation which passes through a known volume of gas. For example, CO absorbs

wavelengths of about 4.2-4.5 μm [4]. The energy present in this range is compared to a

wavelength outside the range; the difference in energy present is the concentration of gas

present [4]. A major advantage is the remote sensing capabilities of an infrared sensor; it

does not have to be in contact with the gas to detect it. This allows large volumes of space

to be monitored. This is one reason Codel uses infrared for monitoring inside tunnels.

Another advantage for tunnel application is its ability to detect high levels of carbon

monoxide from vehicles [4].

1.2.3 Semiconductor

This sensor uses chemical reactions to detect the presence of gases when it comes in

contact with the sensor. The electrical resistance in the sensor decreases when it comes in

contact with the gas. This change is resistance is used to calculate the gas concentration

present. Semiconductors are commonly used for detection of carbon monoxide but the

downfall of this technique is the sensor must come in contact with the gas and therefore

works over a much shorter distance than infrared detectors [5]. This is why semiconductor

sensors are generally not used in tunnel applications.

1.2.4 Ultrasonic

Ultrasonic gas detectors detect changes in background noise in the local environment by

acoustic sensors. This system is generally used to detect gas leaks; high pressure leaks will

produce sound in the ultrasonic range. This is distinguished from the background acoustic

noise. They cannot measure concentration so are not used in tunnel applications [6].](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-10-2048.jpg)

![10 | P a g e

1.3 A Comparisonof CODELsensors andalternative Manufacturers

1.3.1 Key DesignParameters

Codel uses open path optical absorption technology. This has proved to be reliable and

highly accurate. However for optimum results a few key parameters must be met.

1.3.2 Path Length

The longer the path length the more gas is being measured, however this does not mean it

will produce more accurate data. An open path measurement system uses an optical

arrangement where a large broader beam is used to null the impact of optical

misalignment. The amount of energy received by the sensor reduces with the square of the

path length. This reduces the signal noise as the path length is increased. So we have two

conflicting parameters that decide the overall accuracy of an open path measurement

system. The measurement sensitivity increases with path length, while signal noise reduces

with the square of the path length. Both improve the signal noise ratio for the device. Codel

solution to this problem is to choose the shortest path length consistent with achieving the

required measurement sensitivity.

Codel Tunnel Craft 3 measures CO, NO and visibility over a path length of 6 metres, 3 m

from the transceiver to the reflector and vice versa. This ensures all three measurement

channels high accuracy will be comfortably satisfied. Other manufacturer’s sensors require

longer path lengths such as ten metres to achieve their specified accuracy [7]. This will

cause increased measurement noise. This is one major disadvantage of other products on

the market. A further disadvantage of long optical path length is it is unrealistic to maintain

accuracy over a wide measurement range when using a long path length. The Codel sensor

has the ability to maintain its accuracy over the full operating range of 0 to 300 ppm [7].

1.3.3 Choice of Infrared Detector

Codel uses a high quality thermo-electrically cooled lead selenide detector to achieve the

required sensitivity. For the 3 metre folded beam path it can maintain its accuracy for CO

measurement of 1 ppm for the range of 0-300 ppm. In comparison to other competitors](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-11-2048.jpg)

![11 | P a g e

sensors which use less high tech and cheaper pyroelectric detectors, having an accuracy

spec of only 5 ppm over a 10 metre path for the range 0-150 ppm [7].

1.3.4 Measurement of NO

Codel’s use of the lead selenide detector enables them to integrate a measurement channel

for NO into the tunnel sensor; this is not possible with other manufacturer’s pyroelectric

detectors. Codel sensors are unique in their ability to provide three key measurements (CO,

NO, Visibility) in the one sensor [7].

1.4 Theory

1.4.1 The Tunnel Craft 3 Concept

The device is designed exclusively for road tunnel applications. It can monitor carbon

monoxide, nitric oxide and visibility. Operating costs are at a minimum with the sensor

design having only one moving component and routine maintenance is simply cleaning of

the optical lens. There is also minimum tunnel cabling used and low installation costs.

Remote access of the diagnostic data and calibration input commands simplifies and

reduces the need for tunnel access.

1.4.2 What gases are measured and why?

Tunnel monitoring is extremely important for the health of its users as there is a risk to life

due to the gases involved. The combustion process along with exhaust fumes provides a

range of harmful toxic substances. The main players are carbon monoxide and nitric oxide.

Visibility is also a key issue for tunnel monitoring. Visibility is a measure of the distance at

which an object or light can be clearly distinguished. Vehicles release many gases which

can give a fog affect which in turn reduces visibility. In the still air of a tunnel environment

with little wind, a build-up of gases could be very detrimental to the visibility of the

drivers. Carbon monoxide and nitric oxide is a product of internal combustion engines, if

high levels are present these gases can easily cause fatal injuries. CO is non-smelling and

uncoloured at room temperature. It replaces O2 molecules in haemoglobin causing

suffocation. Therefore it is very important to continuously monitor, ventilate and if needed

raise an alarm when the prescribed limits are breached in the tunnel air.](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-12-2048.jpg)

![12 | P a g e

The acute effects produced by carbon monoxide in relation to ambient concentration in

parts per million are listed below:

Figure 1: CO Exposure Effects [1]

Gas detecting levels are generally drawn up in consultation with medical experts; however

the connection between gas concentrations and toxicity depends on many factors for each

tunnel. This makes it difficult to define exact limits for gas detection as each tunnel is an

individual case [8]. In comparison with ambient air, tunnel air is more stable as there is not

as much wind present. Wind can dilute pollution rapidly and disperse the pollution

concentration. This increases the need for low levels pollution in the tunnel environment.

In summary the three parameters stated are the main safety concerns in a road tunnel and

the Tunnel Craft 3 can monitor and detect them with high accuracy using the one sensor.

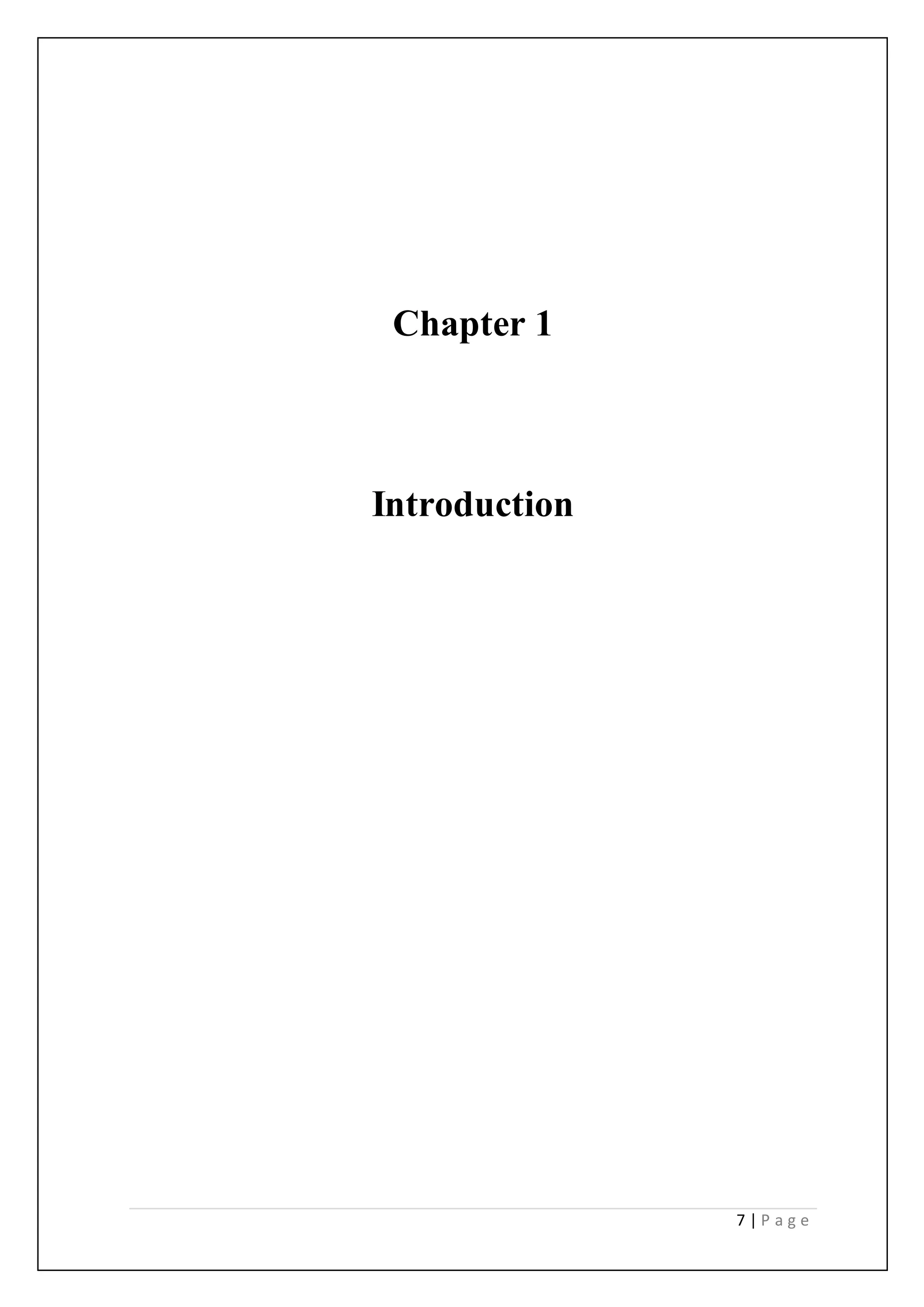

1.4.3 CO, NO and Visibility Air Quality Monitor

The AQM uses both infrared and visible light channels to measure visibility, carbon

monoxide and nitric oxide. The system consists of a transceiver that projects visible and

infrared beams to a reflector mounted 3 m away.](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-13-2048.jpg)

![14 | P a g e

Figure 4: Reflector

The specific absorption is measured to determine the visibility, CO /NO concentrations

within the path of the beam. A high powered LED is used for visible light source (See

Figure 2) while an infrared thermal source provides the infrared energy (See Figure 2). A

silicon photo-detector is used to measure the optical visibility; it determines the attenuation

of the light beam along the instruments sight path due the particulates present in the tunnel

atmosphere (See 1.6.1.4). The carbon monoxide and nitric oxide are measured using gas

cell correlation technology; it investigates the infrared absorption due to the presence of

CO and No in the instrument sight path (See 1.6.2.1). This provides a measurement for

atmosphere concentration in ppm.

1.4.4 Absorption of light

The absorption of light reduces the transmission of light as the atoms/molecules take up the

energy of a photon of light. Therefore due to the gases present in the tunnel, the reduction

of transmitted light is exponentially related to the concentration of the gas and the path

length of light travelled. In this case the path length is about 6m (distance from transceiver

to reflector * 2) [1].

1.4.5 Absorption spectrum of CO

‘’An absorption spectrum occurs when light passes through a cold, dilute gas and atoms in

the gas absorb at characteristic frequencies; since the re-emitted light is unlikely to be

emitted in the same direction as the absorbed photon, this gives rise to dark lines (absence

of light) in the spectrum’’ [9].](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-15-2048.jpg)

![15 | P a g e

The absorption of light reduces the transmission of light as the atoms/molecules take up the

energy. The IR spectrum of carbon monoxide has a major absorption band at 2100 cm-1 or

4.8 µm. The second absorption band seen below is carbon dioxide (CO2) whose absorption

band ranges from 2000- 2400 cm-1. Nitric Oxide has a major absorption band at 1886

cm1 or 5.3 µm.

Figure 5: CO Absorption Spectrum [10]

1.4.6 Beer-Lambert Law

Beer-Lambert Law relates the transmittance of light to absorbance by taking the negative

logarithmic function, base 10, of the transmittance observed by a sample, which results in a

linear relationship to the intensity of the absorbing species and the distance travelled by

light [4].

Absorbance = 2 - Log10 (T)

In summary, the law states that the absorbance is directly proportional to the concentration

of the sample and the path length [1].

1.5 Equipment

1.5.1 Power Supply Unit (PSU)

The power supply unit converts the mains supply to the 12v or 24v DC required to power

the air quality monitor.](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-16-2048.jpg)

![16 | P a g e

Figure 6: Power Supply Unit [1]

1.5.2 Station Control Unit (SCU)

The station control unit provides 48v dc power for the sensors on its local data bus. The

power supply unit provides the power input to the SCU. A local data bus links the SCU to

the sensor. The bus has two serial communication lines, MOSI (master out slave in) and

MISO (master in slave out). Master/Slave is a model for communication where one device

has control over other devices. The role of the station control unit is to access data from the

sensors to provide analogue and digital outputs. This data can be obtained via the RS232

serial port located inside the station control unit. WinCom software can be used to

communicate with the station control unit [1].](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-17-2048.jpg)

![17 | P a g e

Figure 7: Station Control Unit [1]

Description of the cards from right to left:

RS232 connection- this communicates data from the AQM sensor to the laptop

Relay output card- the relays can act as switches or as amplifiers ( converting small

current to larger)

Current outputs- provides mA outputs

Master micro- card contains microprocessor and software control

Slave Micro- card contains microprocessor and software control

Power supply card- includes 10 watts DC-DC converter

Communications card- includes communications to SCU and CDC

1.5.3 WinCom Software

This is the software to be used to communicate the data from the RS232 port in the station

control unit to the user’s laptop. It enables all system data and controls to be accessed from](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-18-2048.jpg)

![18 | P a g e

the laptop. This software package can log data and graph it on the computer screen. Further

exploration of the software and its capabilities will be done at time of implementation and

testing.

Figure 8: General Screen Characteristics [1]

We can see above (figure 7) Codel’s WinCom software screen set up.

1.6 Principles of Operation

1.6.1 Air Quality Monitor

1.6.1.1 Visibility Measurement

This method of presenting this data is in the form of meteorological visibility. This is

defined as the distance over which the intensity of transmitted light falls to 5% of its initial

value. It represents the distance over which a person can see in a hazy or dusty

environment. I/Io is the ratio of the measured beam intensity and that of the initial intensity

Io and is known as the transmissivity (T) of the system.

In this case, I = 0.05 x Io thus T = 0.05](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-19-2048.jpg)

![19 | P a g e

And since k = 1/L * log e 1/T

Visibility L = 1/K log e 20 = 2.99/K

Where k is a parameter known as the visibility coefficient and is proportional to the

concentration of the suspended particles and L is the path length of the beam.

Thus, for a k value of 0.003, the visibility in metres is 2.99/0.003 = 1000m.

Both k factor and visibility are calculated by the sensor and are available for output [1].

1.6.1.2 Measurement Elements

A pulsed LED produces a beam of light focused by a lens to the reflector. The reflector has

an internal detector which monitors the brightness of the pulses of light. The beam

reflected is gathered by a second lens and focussed onto a receiving detector. The ratio of

signals of the two detectors provides the measurement of transmissivity. Transmittance is

the fraction of incident light at specific wavelength which passes through a sample, in this

case which is air.

1.6.1.3 LED Control

The LED emitting operation is controlled by an on board processor. A series of light pulses

is applied to the LED 4 times a second. Each pulse is extremely short in duration and the

pulse stream consists of approx. 100 pulses. The very brief nature of these pulses allows

the device to operate without interference from other light sources within the tunnel.

1.6.1.4 Detector Element

The initial brightness of the emitted light (Vis Tx) is measured by a silicon detector, while

another detector measures the intensity of the received light (Vis Rx) after transmission to

and reflection from the reflector.](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-20-2048.jpg)

![20 | P a g e

Figure 9: Silicon photo-detector [9]

The photo-detector contains pin photodiodes that utilize the photovoltaic effect to convert

optical power into an electrical current.

To monitor the background levels of light intensity the processor takes measurements prior

to pulsing the emitter LED. Then a series of measurements is taken with the LED on and

another series of measurements when it’s turned off to check the background levels

haven’t changed. This process occurs at high frequency which reduces the effects of any

background lighting [11].

1.6.1.5 Diagnostic Data

From the two detector measurements the transmissivity and opacity are calculated. Opacity

is a direct reading of the attenuation of light .It is a measure of the impenetrability. Zero

opacity equated to a totally clean light path and 100% to total light attenuation.

The measurement of opacity relies on having clean optical sources. If the surfaces of the

lenses or reflector become contaminated there will be a reduction in intensity of received

light and therefore an increase in opacity value. Over long periods of time this build-up of

contamination of lenses would result in a steady increase in opacity value. This appears as

a positive output drift. To fix this problem the optical surfaces should be cleaned regularly,

this could be a problem in a road tunnel but for this commissioning project it is a simple

but effective solution.](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-21-2048.jpg)

![21 | P a g e

1.6.1.6 Calibration

Normal procedures would all for calibration during a tunnel closure when it is expected

that the opacity value will be zero. The instrument can also be calibrated by selecting a

calibrate mode, where an opacity value of zero is assumed and the relevant calibration

factor is calculated:

Set Cal Vis = 10000 x Vis Tx/Vis Rx

Where Vis Tx is visibility transmitted from the transceiver and Vis Rx is visibility received

from the reflector.

1.6.2 CO & NO Measurement

Both Carbon Monoxide and Nitric Oxide absorb infrared energy. Both spectra behave like

a typical diatomic gas. They are made up of a number of fine absorption bands. Carbon

monoxide is fixed on a wavelength of 4.7 µm and Nitric Oxide 5.3 µm. This spectrum

allows gas cell correlation to take place in the analysis to determine the concentrations of

gases present.

The ratio of measurement of attenuation of infrared beam with and without a high

concentration of sample gas being measured allows us to derive a function which is

dependent solely on the concentration of gas to be measured. The advantage of this

technique is it uses a sample of the gas itself as a filter so it has extremely high immunity

to other interfering gases.

1.6.2.1 Gas Cell Correlation

This technique is ideal for a tunnel monitoring system as it is built to detect low level

measurements. It also has the ability to operate where there are background gases present

which could interfere with the measurement. The sensing mechanism is based on the

absorption principle where the gas can absorb unique light wavelengths. The principle is

simple, light travels through the gas to be measured and the difference in absorbance is

measured and provides the output of gas concentration [12].](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-22-2048.jpg)

![22 | P a g e

1.6.2.2 Measurement Elements

The infrared source generates an infrared beam. The lens focuses radiation from this source

toward the reflector. Energy is received and reflected back to the transceiver. A second

lens focuses this energy onto a highly sensitive infrared detector. Right in front of the

detector sits a wheel containing four sets of filters, two for nitric oxide and two for carbon

monoxide. Each pair of filter has one sealed gas cell containing 100% pure CO for the CO

channel and 100% pure NO for the NO channel. A stepper motor rotates the wheel at a

constant speed of 1 Hz. It is under the control a processor. The four channels sweep across

the infrared beam, the processor digitises the detector output produces four signals, D (CO)

measurement, D (CO) reference, D (NO) measurement and D (NO) reference. These

values are used to compute the parameters Y (CO) and Y (NO) which are unique functions

respectively [1].

1.6.2.3 Detector Operation

The detector is made from Peltier cooled lead selenide element. It has a very high

sensitivity to infrared energy. The element must be cooled to approx. -20°C to obtain the

necessary response. This is achieved by the thermoelectric Peltier cooler. The temperature

of the detector element is monitored by a thermistor. This in turn is monitored by a

processor and controls the current output applied to the Peltier cooler to achieve the stable

required temperature [1].

1.6.2.4 Stepper Motor Control

The stepper motor is driven by a frequency signal from the supervisory processor. The gas

cell wheel operates at exactly 1 Hz. The processor knows exactly when to digitise output in

order to obtain the signals for calculation of CO and NO concentrations [1].

1.6.2.5 Integration of CO/NO & Visibility Measurements

The CO/NO and visibility channels are all operated by the supervisory processor to ensure

data from all channels is obtained systematically and consistently. All four detector

measurements from the four gas cells in the wheel are digitised by the processor. In

between this happening the measurement for visibility is made [1].](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-23-2048.jpg)

![23 | P a g e

1.6.2.6 Calibration

The instrument can be switched to calibration mode. The Y value is set to zero on the basis

that pollutant levels are zero and the formula:

SC =

8000 ∗D Reference

D Measured

Is used to calculate the calibration constant SC [1].

1.7 TechnicalSpecifications

1.7.1 General

Construction of the device is a corrosion resistant epoxy coated aluminium

housings sealed to IP66 (AQM & PSU)

Ambient Temperature is -20°C to +50°C

1.7.2 Sensor Unit

Measuring units are ppm for CO & NO, and metre(m) for visibility

Path length 3 m (6 m folded beam)

Measurement range for CO & NO 0-1000 ppm, this is the range for which the

error obtained does not exceed the maximum permissible error

Accuracy of +/- 1 ppm, it is used to describe the closeness of a measurement to the

true value

Resolution of +/- 1 ppm, this is the smallest change a sensor can detect in the

quantity that it is measuring

Response time of 2 minutes for CO & NO, this is the time taken by the sensor to

approach its true output after being subject to corresponding input

Calibration time of at least 20 minutes is needed, a 10-second interruption of the

optical beam will cause the sensor to switch to calibration mode (after a power

interruption the sensor will need 240 minutes of calibration)

Drift of the analysers will occur over time. The sensor operates an auto-zero

technique. This is based on assumption that there will be periods in the tunnel](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-24-2048.jpg)

![24 | P a g e

where pollutant levels are zero (night time when traffic is light). If the drift is

positive the sensors output reduces slowly and evenly with time. The rate of

reduction is adjustable. When the analyser displays a negative drift (pollutant levels

are zero) the analyser is programmed to readjust its calibration, this effectively

makes every period of zero pollutant to reset the calibration of the device. The rate

of decay of output is adjustable from 1 ppm per day. The errors involved in this

technique are held within the overall specified accuracy of the instrument provided

that zero pollutant calibration occurs reasonably frequently (once per day).

1.7.3 Power Supply Unit

Output of 12V or 24V DC fused, maximum current output must not exceed 5A

(60W)

1.8 Device Wiring

1.8.1 Wiring Power Supply Unit

The wiring of the power supply unit is straight forward with the mains power coming in

top right hand side of the unit. The live, neutral and earth connections are wired in here.

Figure 10: Power Supply Unit [1]

The 48v outputs will be wired into the current outputs card in the station control unit.](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-25-2048.jpg)

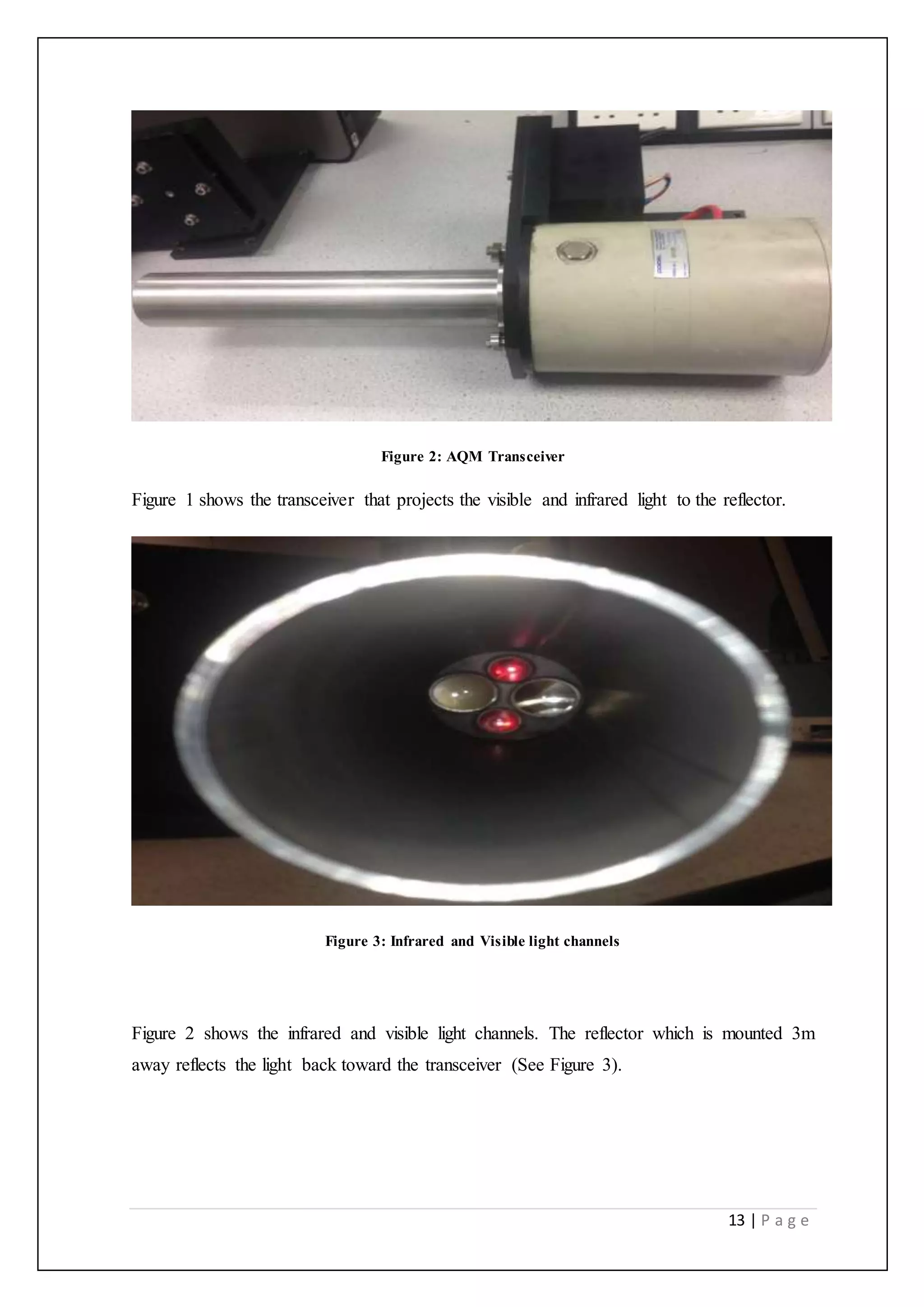

![25 | P a g e

1.8.2 Wiring Station Control Unit

The wiring of the station control unit is more complex but the following schematic

provides excellent graphic illustration of what is required.

Figure 11: Station Control Unit Schematic [1]

Keep links in place are important wire connections from the power supply unit to

the air quality monitor

The output from the power supply unit is connected into the power supply card

seen in the above schematic

The communications card is wired into the air quality monitor connectors (red,

blue, black, yellow) on the bottom left of the above schematic

The power supply is wired into the power supply card in the SCU and to the current

output card and the relay card

The RS232 communications is connected into the users laptop operating WinCom

software](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-26-2048.jpg)

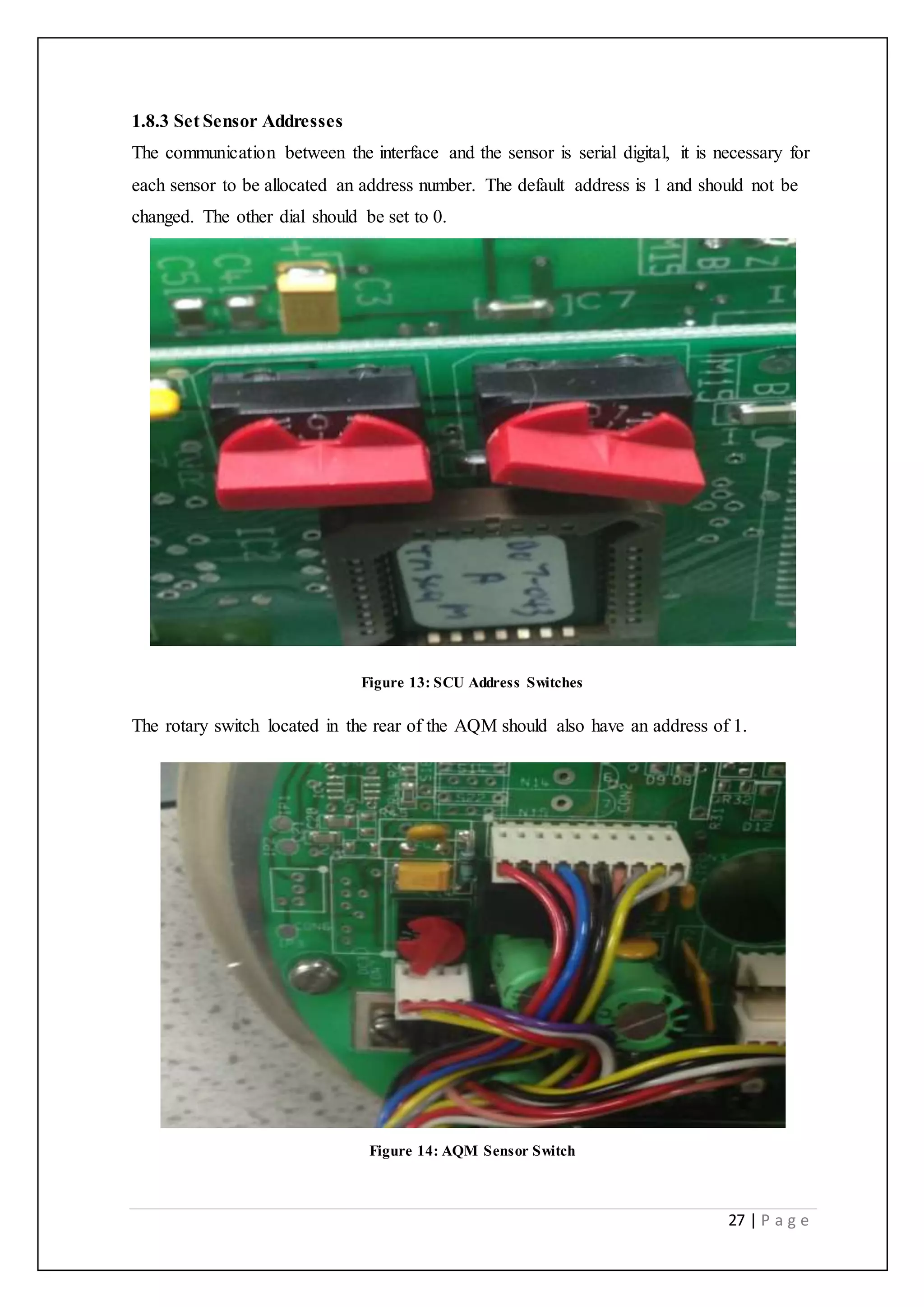

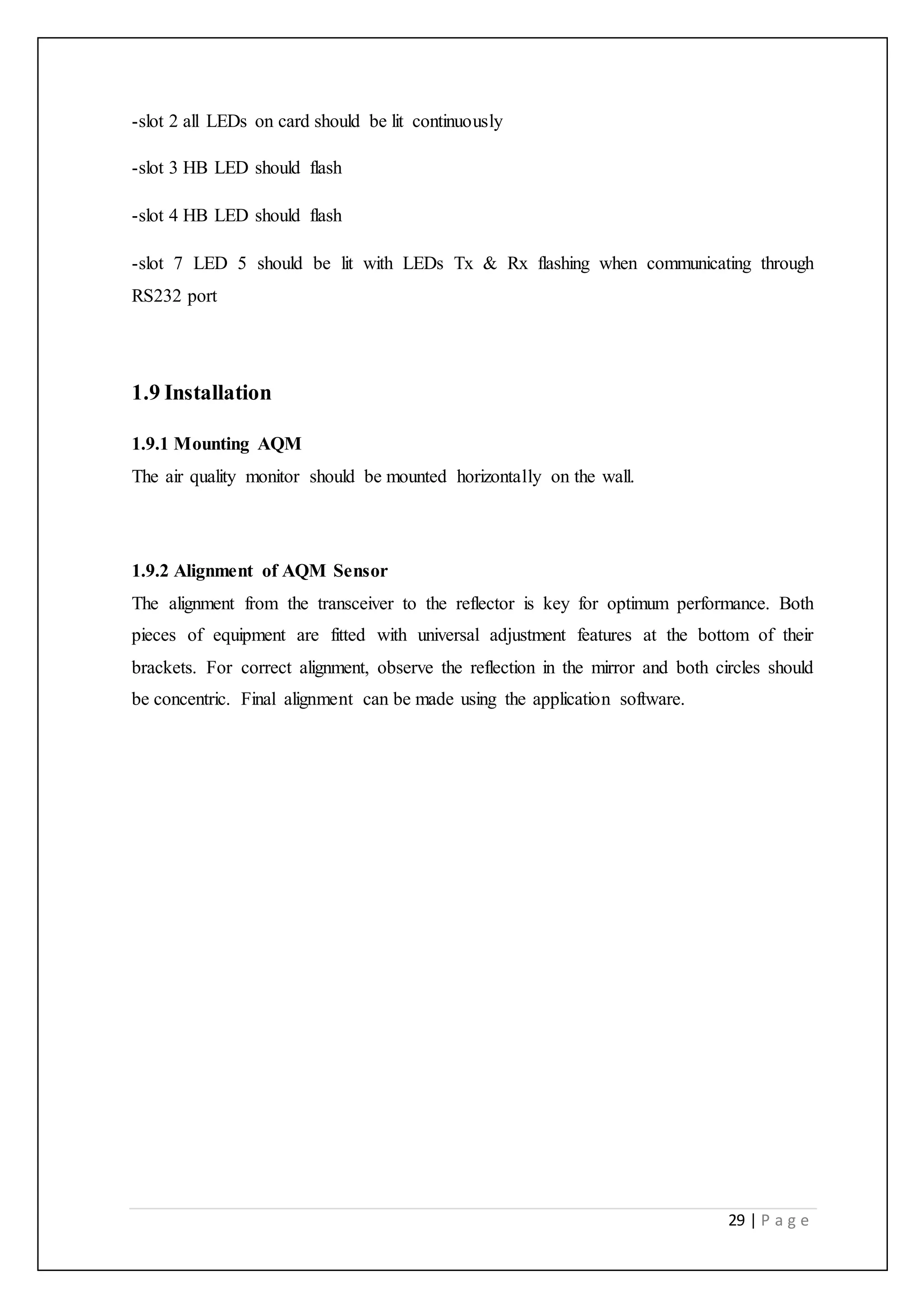

![33 | P a g e

2.1.1Wiring the RS232 Communications

The RS232 connection had to be soldered together, the following schematic was used:

Figure 18: RS232 Female Pin out [13]

The connection was soldered together using the above pin out.

Figure 19: RS232 Soldered Connection](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-34-2048.jpg)

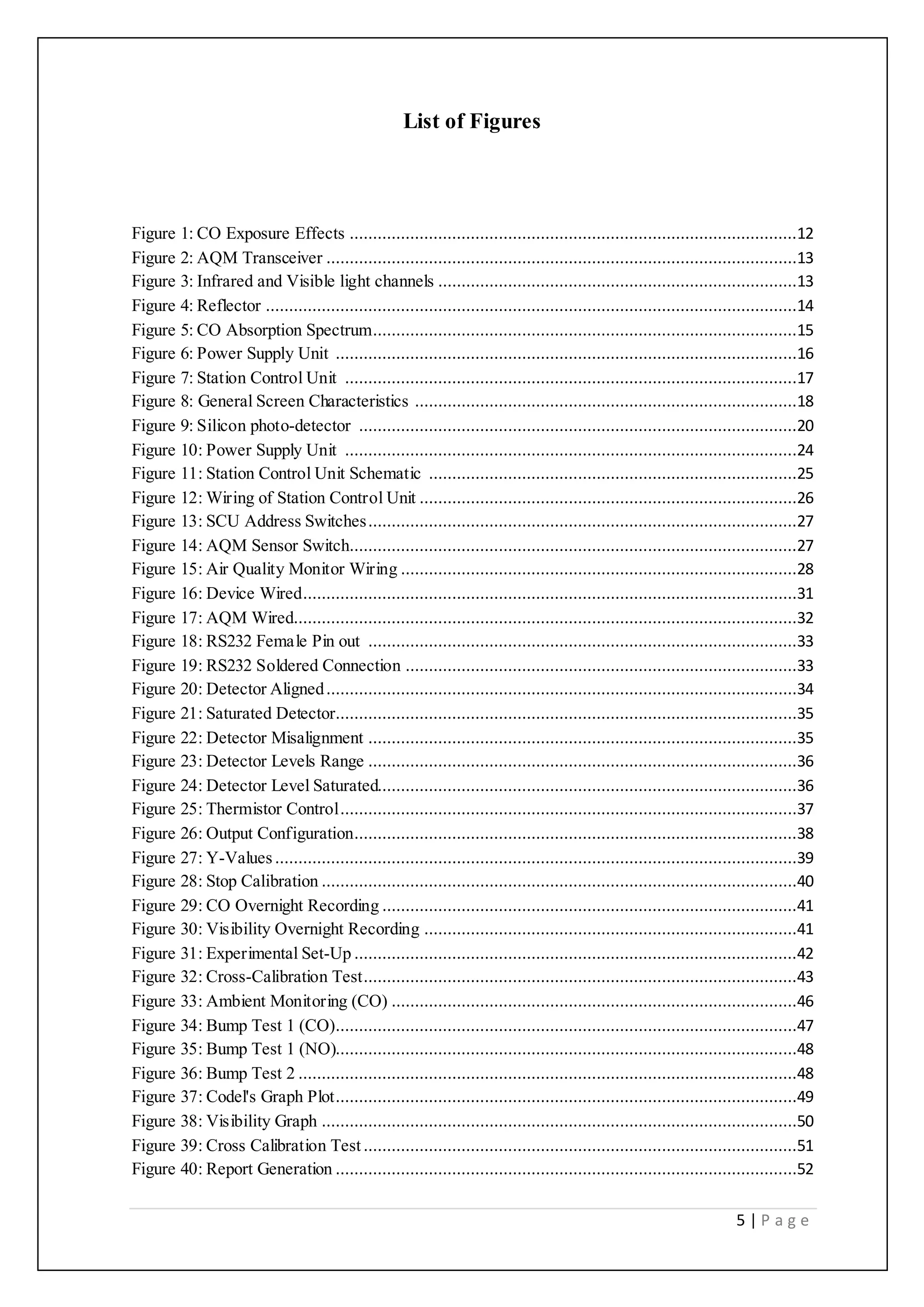

![36 | P a g e

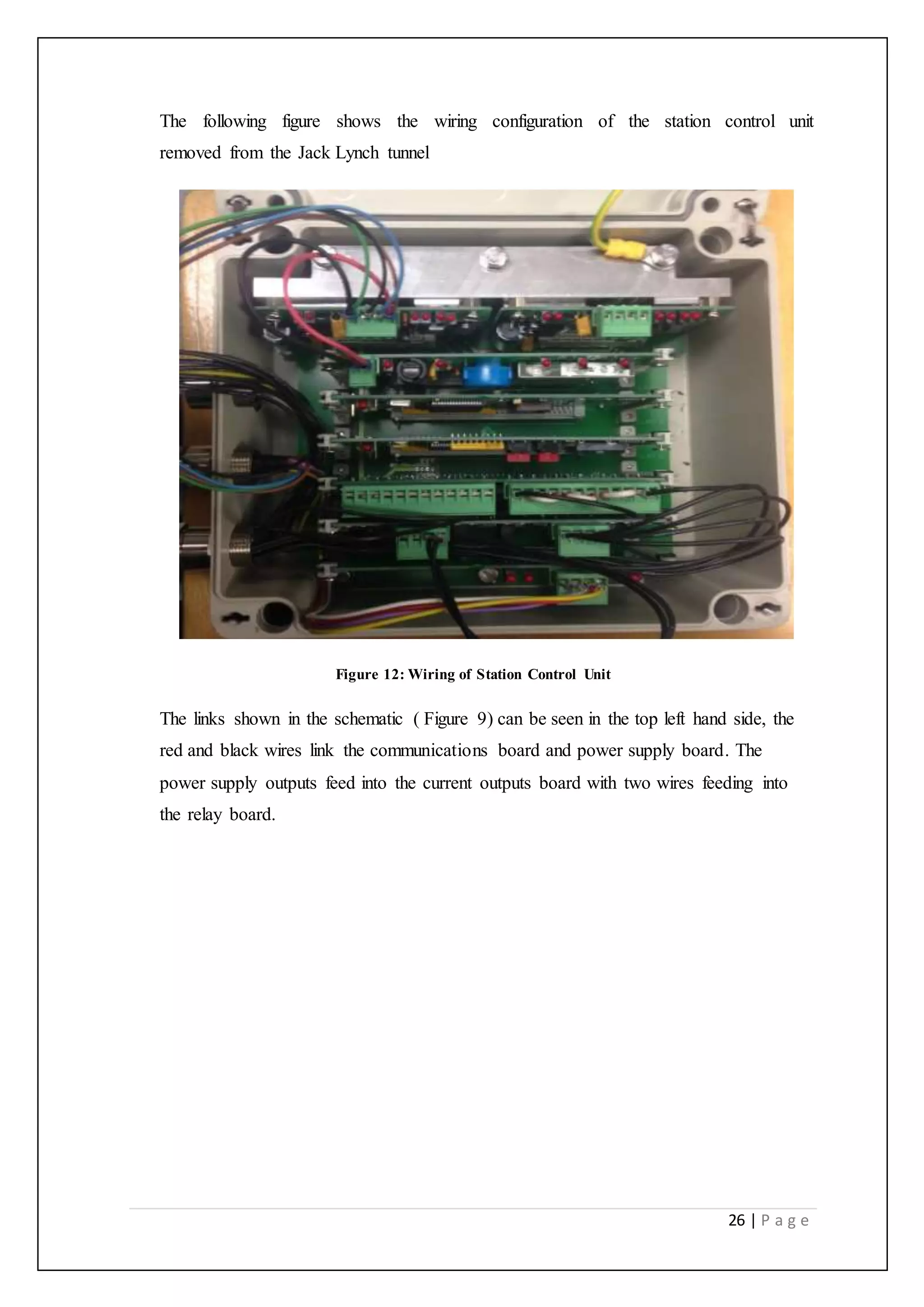

2.2.2 Detector Levels

The detector levels indicate the typical ranges for the measurements parameters. The

following image indicates the typical ranges for correct performance:

Figure 23: Detector Levels Range [1]

The measurement process will indicate a detector saturation condition by switching the

saturation indicator from green to red if the signal strength of the detector is too high. The

gain should be reduced if the red indicator is observed.

Figure 24: Detector Level Saturated

Vis Rx is saturated; this can happen if the path length is too short. (3m is recommended)](https://image.slidesharecdn.com/e21e5926-b800-4bd4-8cf0-488a47e07799-150710101311-lva1-app6892/75/Final-Bound-Report-37-2048.jpg)