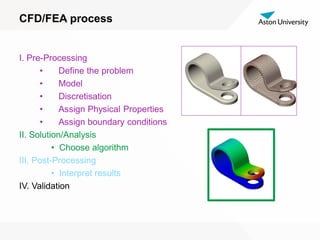

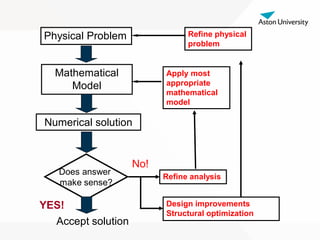

The document summarizes the FEA/CFD process which includes:

1) Defining the problem, creating a model, assigning properties and boundary conditions in pre-processing.

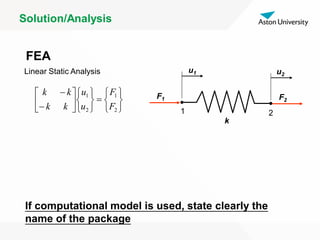

2) Choosing an algorithm and running the analysis/solution in solution/analysis.

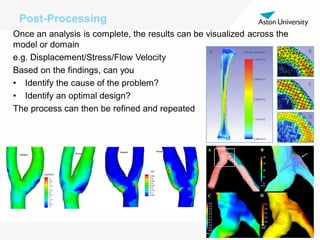

3) Interpreting and visualizing results in post-processing to identify causes and optimal designs.

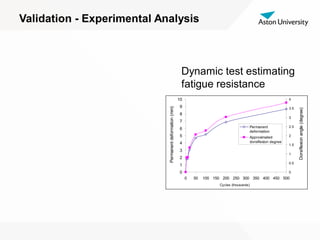

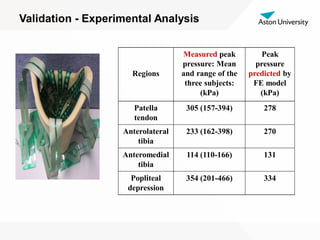

4) Validating simulation results experimentally through methods like 3D printing, dynamic testing, and pressure measurements to verify the model is accurate.