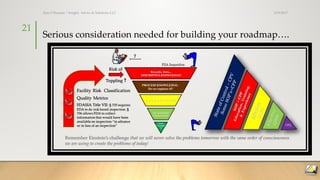

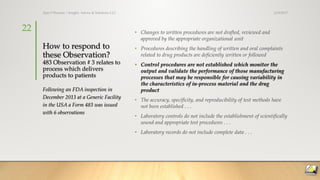

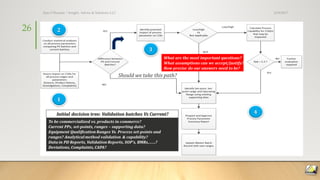

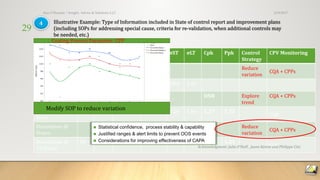

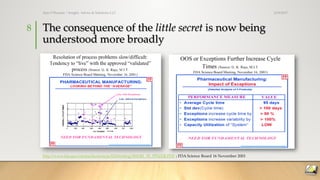

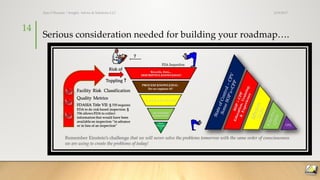

The document discusses FDA trends and new validation strategies in pharmaceutical manufacturing, highlighting the need for a roadmap in process capability. It outlines three approaches for this roadmap: pathfinder, standard, and emergency, while emphasizing the evolution towards real-time controls and continuous manufacturing. The speaker, Dr. Ajaz S. Hussain, shares insights into the intersection of quality assurance, technological advancements, and regulatory dynamics affecting the pharmaceutical industry.

![[Pharmaceutical]

Industrial Revolutions:

1.0, 2.0, 3.0, and 4.0?

• Background: How did the journey

begin in 2000 and progress until 2005?

If you are interested please click on

the video message from the past

• Pharmaceutical cGMPs for the 21st

Century — A Risk-Based Approach

• Today we have an

unprecedented juxtaposition of the

main forces necessary for the US

pharmaceutical manufacturing

renaissance – we are at the Tipping

Point

3/19/2017

Ajaz S Hussain | Insight, Advice & Solutions LLC

4](https://image.slidesharecdn.com/fdatrendsnewvalidationstrategies-170319131931/85/FDA-Trend-New-Validation-Strategies-4-320.jpg)

![What?

• Technology platforms

• Manufacturing with controls [PAT-RTRT partial or full]

• API only, DF only, Integrated API & DF

• Rapid development, manufacturing with controls

• PAT-RTRT with continuous manufacturing

• Other – human behavior motivation & monitoring , Big Data, pattern recognitions, etc.

• New (generic or brand) development Vs. Post Approval

• OSD IR: BCS Class I, Direct Compression,….

• OSD IR: BCS Class IV, Wet Granulation….

• OSD MR: Extended Release

• …….

• People & Organization Development , Partnerships & Collaboration

• Internal mindset shift and collaborations

• Regulator communication and collaboration

• Partnership & collaboration with Suppliers & Technical Experts

• Collaboration with Academia (e.g., NIPTE)

You need to consider

3/19/2017Ajaz S Hussain | Insight, Advice & Solutions LLC

16](https://image.slidesharecdn.com/fdatrendsnewvalidationstrategies-170319131931/85/FDA-Trend-New-Validation-Strategies-16-320.jpg)