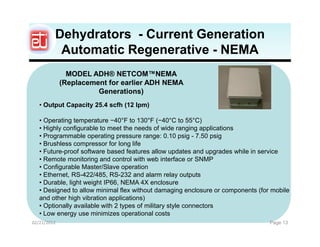

ETI is a privately owned company founded in 1968 that manufactures environmental control equipment like dehydrators. It has been in business for over 35 years and is headquartered in South Bend, Indiana. ETI produces passive, manually regenerated, and automatic regenerating dehydrators to keep transmission systems dry. Their current automatic dehydrator model, the ADH NETCOM, can monitor and control remotely over Ethernet and has a brushless compressor for long life.