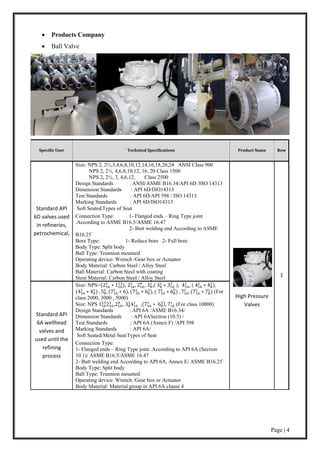

Pishgam is Iran's first knowledge-based company specializing in valves for the oil, gas, and petrochemical industries. It was founded in 2002 and is a member of Pardis Technology Park. Pishgam has designed and produced over 75 families of plug valves up to 20 inches in size. It has expanded its product range over the years and now produces ball valves, butterfly valves, control valves, and other types of valves up to 36 inches in various pressure classes. Pishgam has established two partner companies, Pars Paydar Energy and Petro Pishtaz Atlas, to further develop its production capabilities and infrastructure.