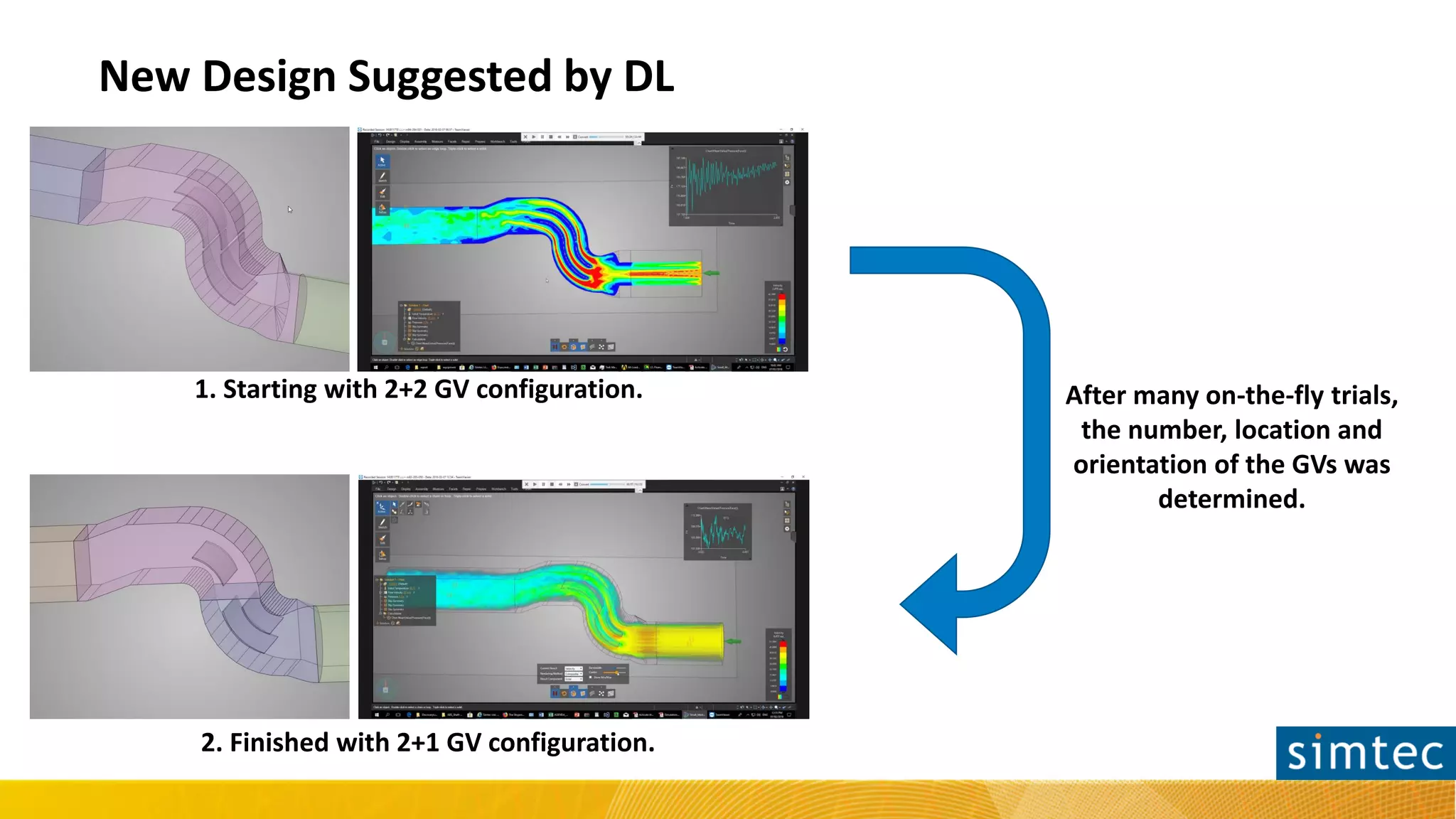

The document describes how ANSYS Discovery Live was used to optimize a pipe section in a power plant that was experiencing unstable and recirculating flow. The pipe section was prone to flow-induced vibrations and had a high pressure drop of 406 Pa. ANSYS Discovery Live was able to quickly test different configurations of guiding vanes on-the-fly to both reduce vibrations and lower the pressure drop. The optimized design of 2 inlet and 1 outlet guiding vane stabilized the flow and reduced the pressure drop to 225 Pa, saving the customer thousands in investment and operation costs.

![Appearance of the Problem

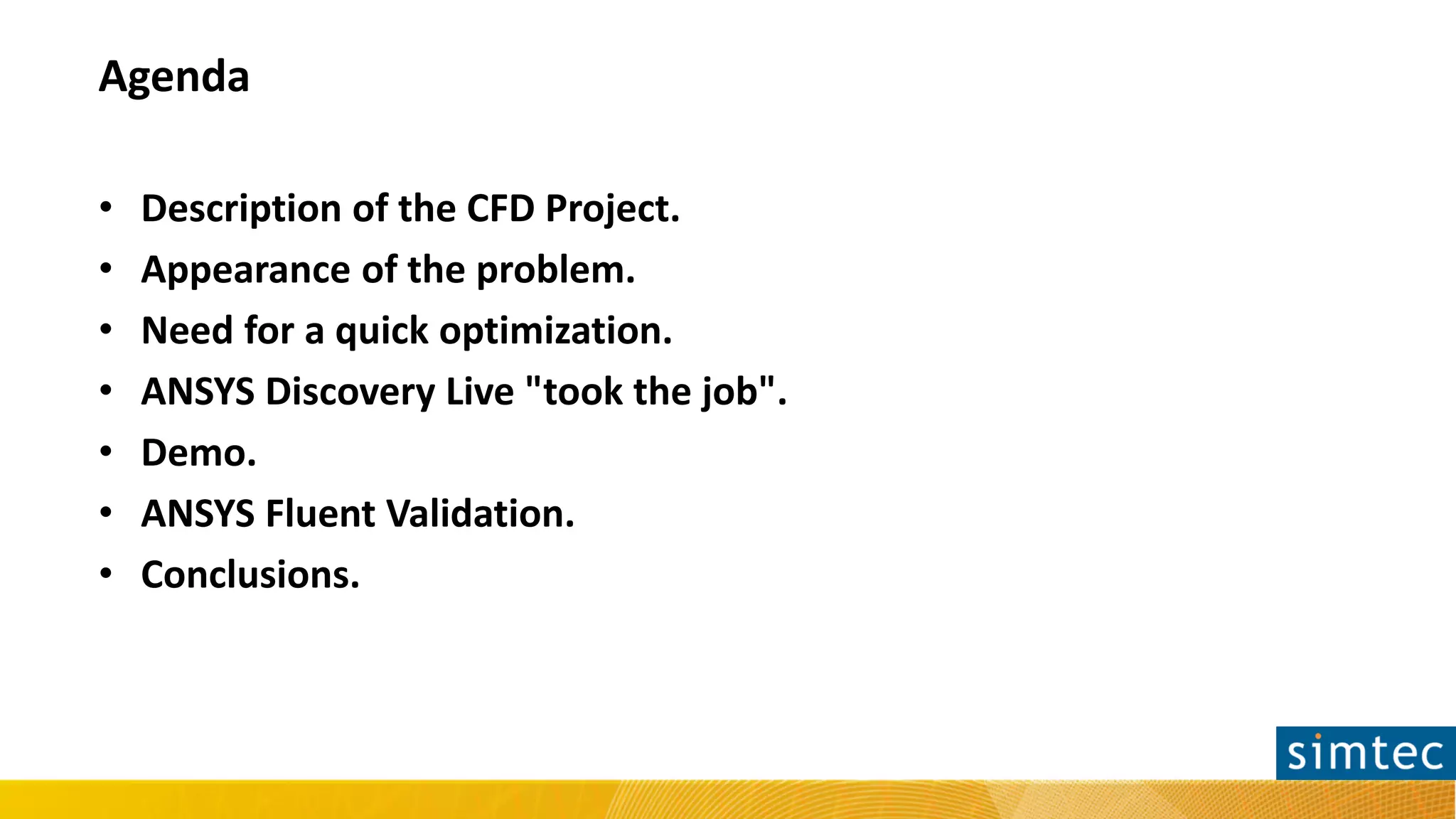

• The "small duct" section is prone to Flow–Induced Vibrations (FIV), due to highly unstable and recirculating flow.

• The simulation was run in transient solver due to flow instabilities.

• Pressure drop (including dynamic head) was calculated to 406 [Pa].

10

30

50

70

90

110

130

150

170

40 41 42 43 44 45 46 47

Pst,in[Pa]

Time [s]

Mean=81.33 [Pa]](https://image.slidesharecdn.com/presentationjpeliminatingflowinstabilities-180711091950/75/Eliminating-Flow-Instabilities-and-Reducing-Pressure-Drop-in-a-Pipe-Section-of-a-Power-Unit-4-2048.jpg)

![10

30

50

70

90

110

130

150

170

40 41 42 43 44 45 46 47

Pst,in[Pa]

Time [s]

Validation with ANSYS Fluent

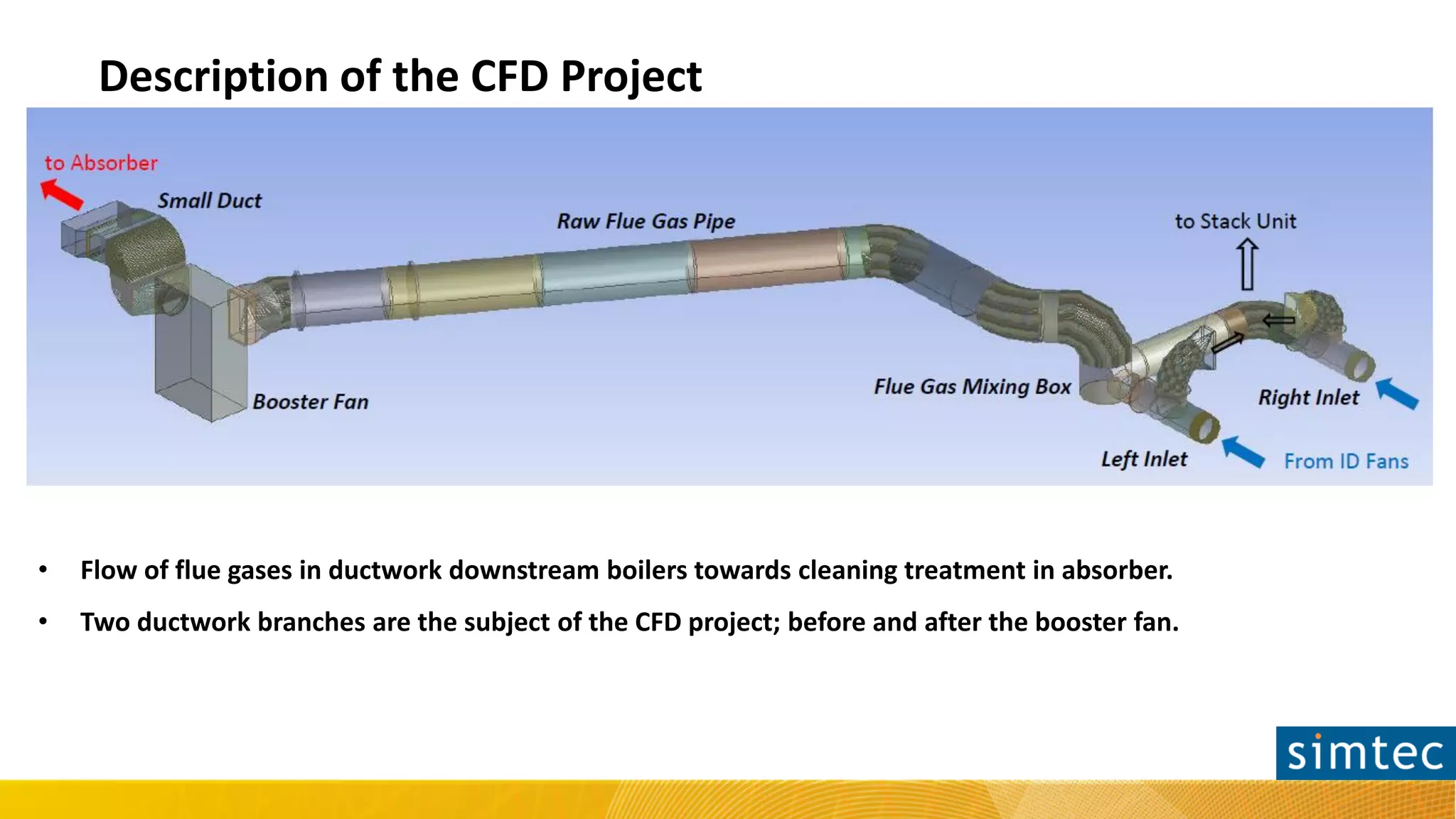

• The instabilities dissappeared and simulation was successfully run in steady–state mode.

• Pressure drop (including dynamic head) was reduced to 225 [Pa].

STEADY STATE achieved!](https://image.slidesharecdn.com/presentationjpeliminatingflowinstabilities-180711091950/75/Eliminating-Flow-Instabilities-and-Reducing-Pressure-Drop-in-a-Pipe-Section-of-a-Power-Unit-9-2048.jpg)

![Conclusions

• A design/optimization question was raised during a real project in a new power station

under construction.

• A quick decision was necessary to resolve a possible FIV issue in the ductwork.

• New product ANSYS Discovery Live was employed and provided on–the–fly insight and

qualitative optimization trends in a few hours.

• The improved design was validated in ANSYS Fluent and was confirmed that eliminates

flow instabilities but also reduces booster fan power by 2 [mbars], translated into

savings for customer (investment and operation cost) of thousands EUROS.](https://image.slidesharecdn.com/presentationjpeliminatingflowinstabilities-180711091950/75/Eliminating-Flow-Instabilities-and-Reducing-Pressure-Drop-in-a-Pipe-Section-of-a-Power-Unit-10-2048.jpg)