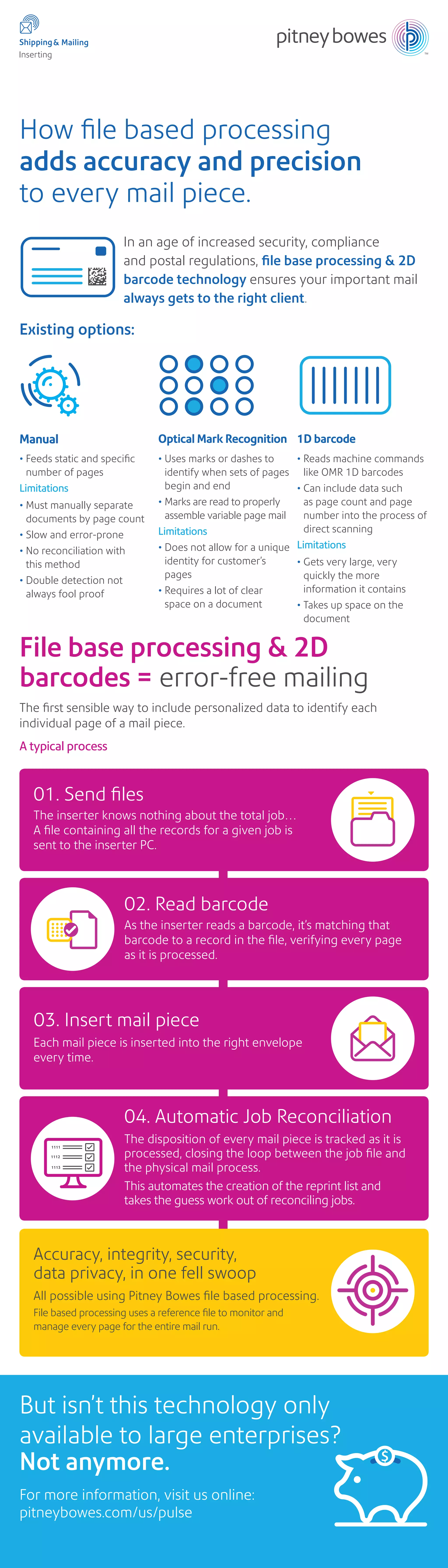

The document discusses the advantages of file-based processing and 2D barcode technology in mail handling, emphasizing accuracy, security, and compliance with regulations. It details how this system automates the reconciliation of mail pieces and tracks their disposition, reducing errors and eliminating manual processes. Additionally, it states that this technology is now accessible to smaller enterprises, enhancing their mailing efficiency.