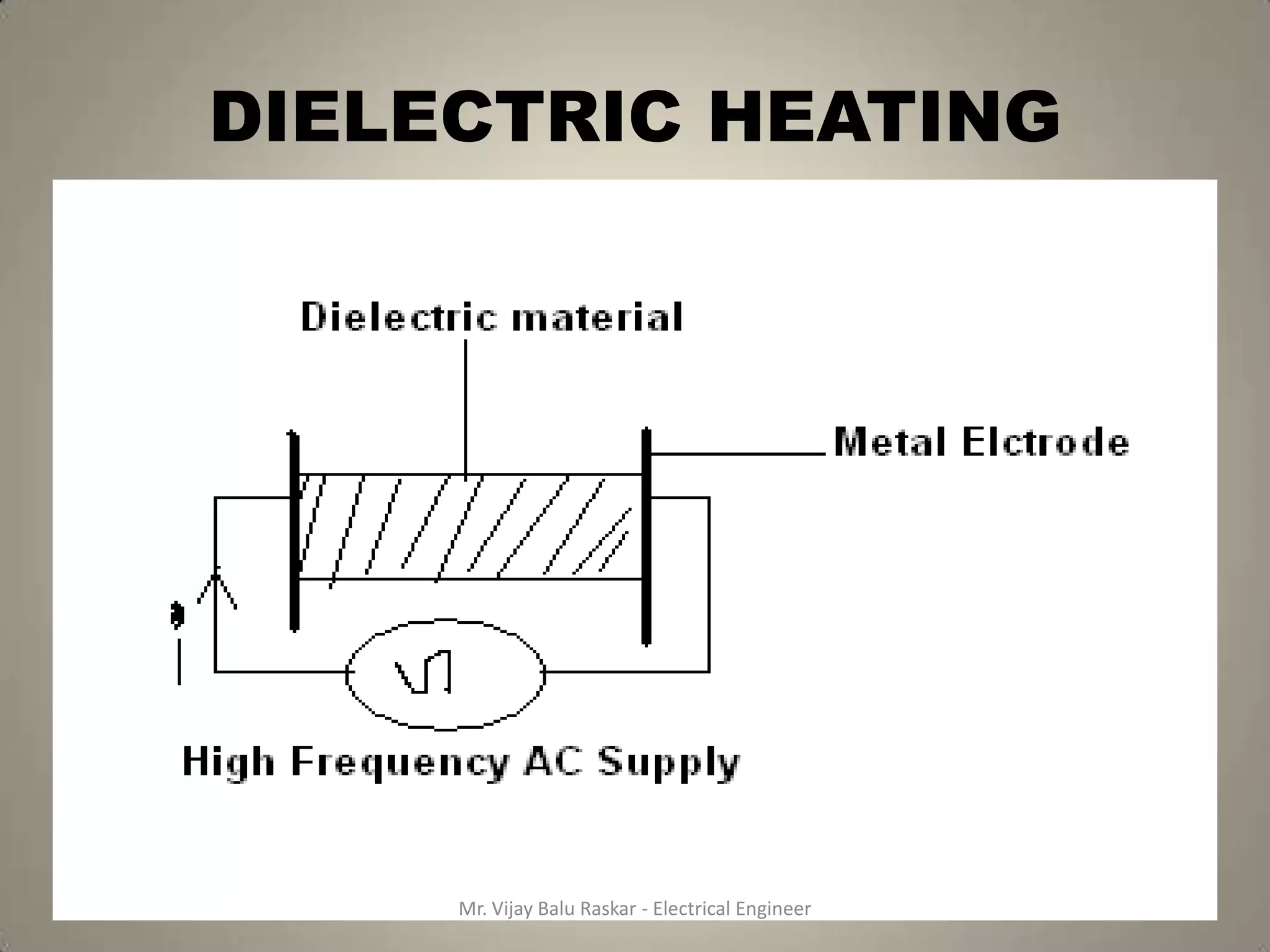

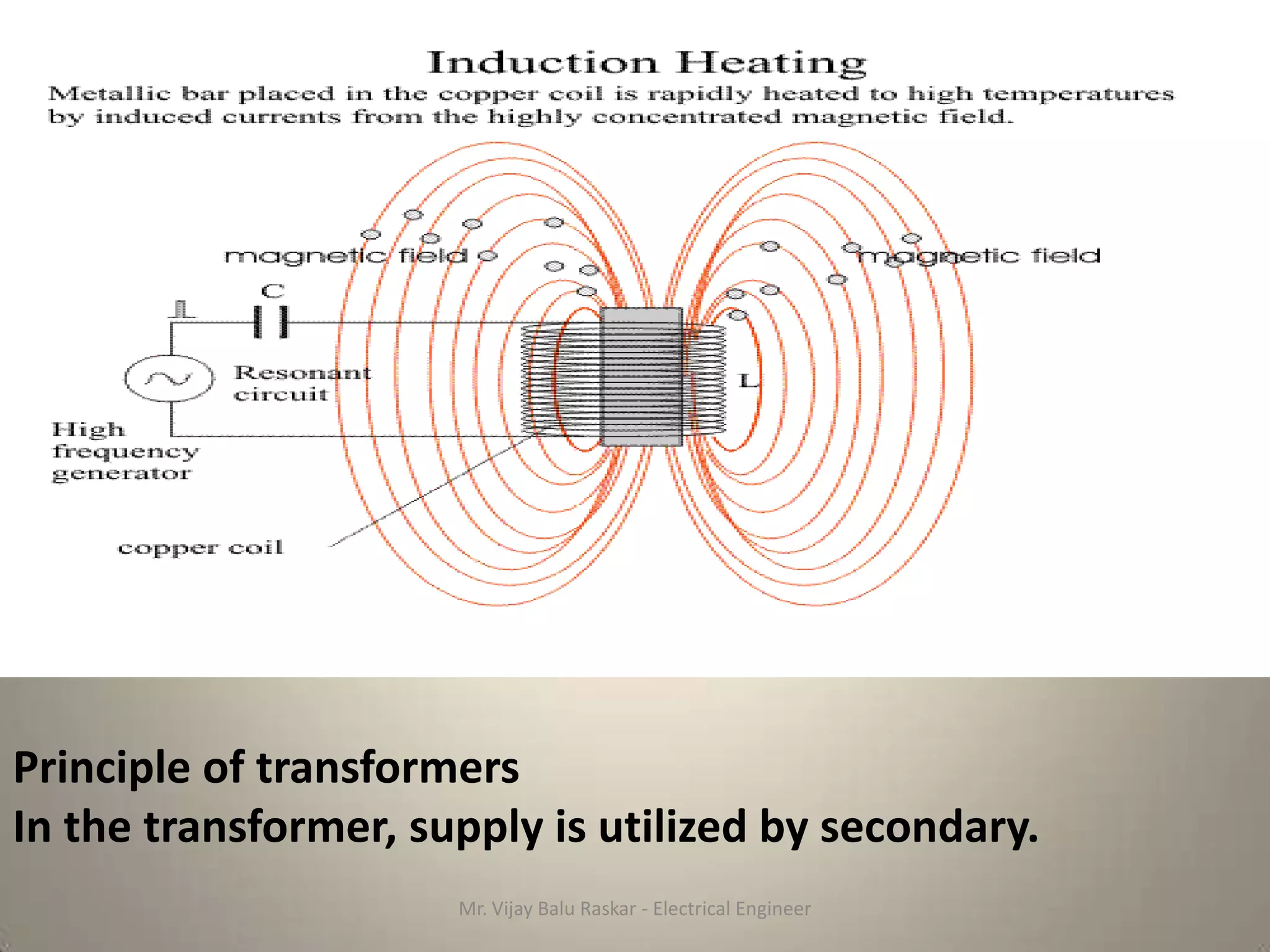

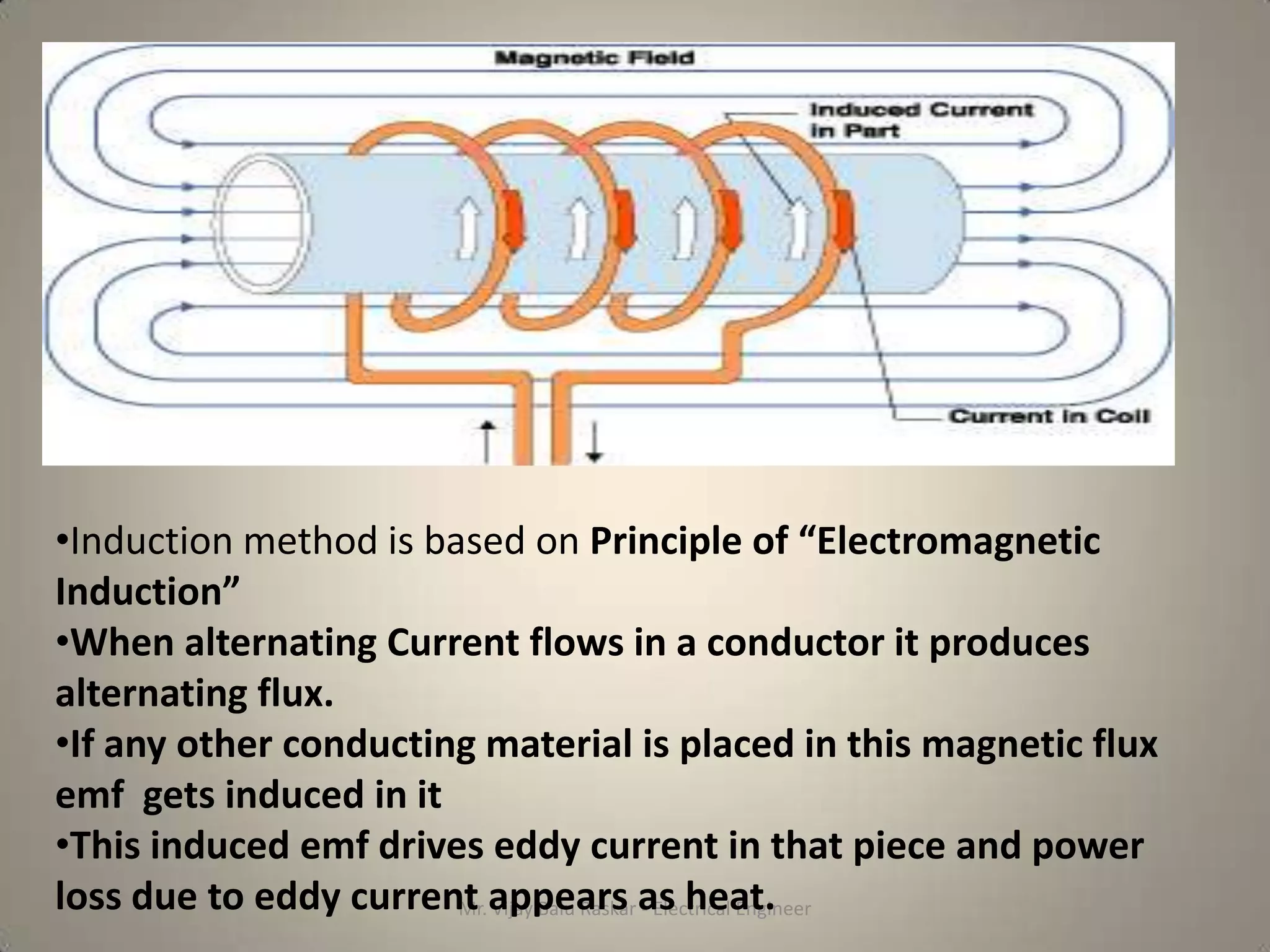

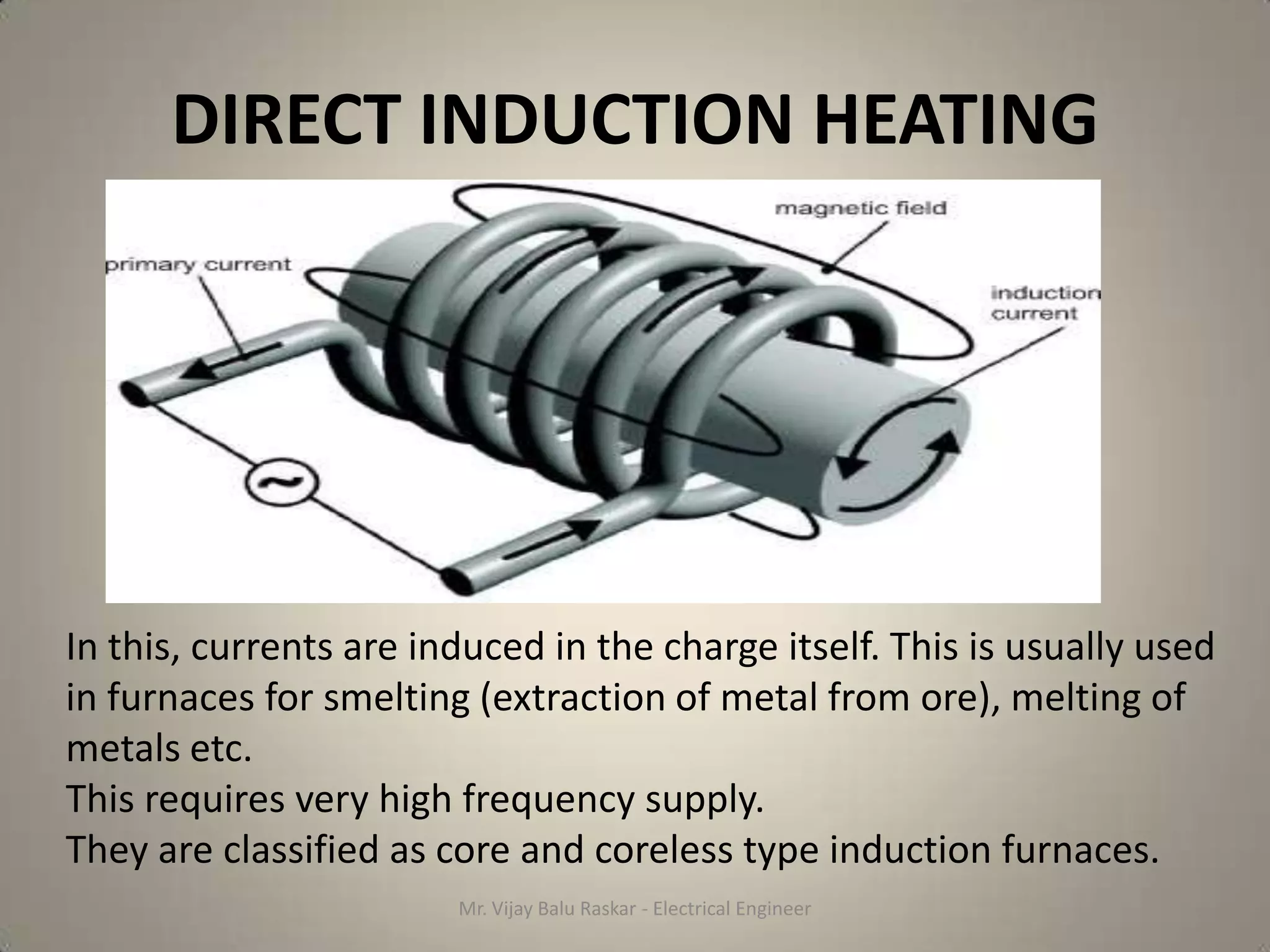

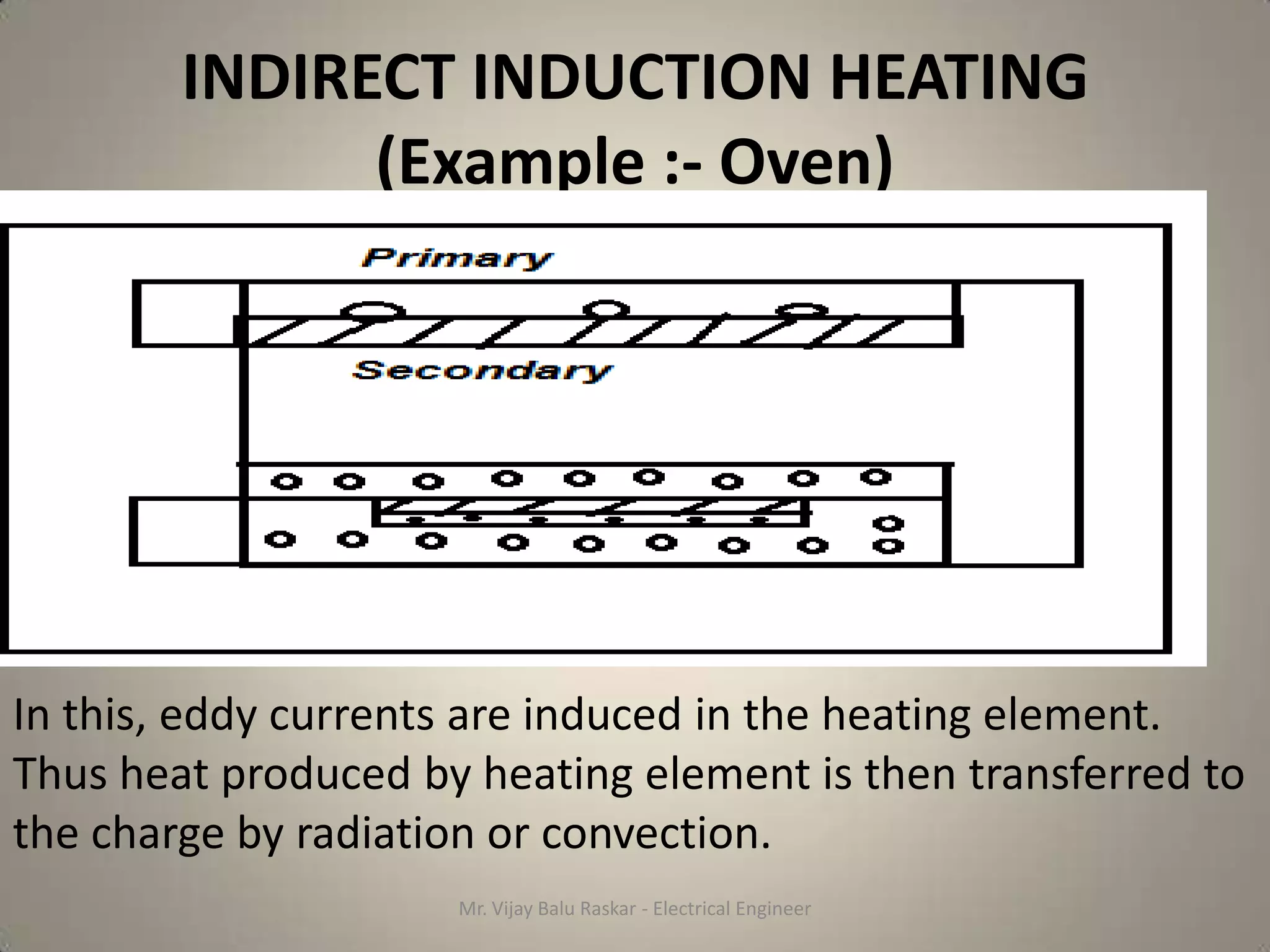

Dielectric heating occurs when a non-conducting material is subjected to an alternating electric field, causing dielectric losses that generate heat within the material. The heat generated is proportional to frequency and voltage. Common applications include heating plastics, food processing, and industrial uses like curing and drying. Induction heating uses electromagnetic induction to generate eddy currents within a conductive material, heating it through resistive losses. It can be applied directly by inducing currents in the target material or indirectly by first heating a container that then transfers heat through radiation or convection. Proper selection of frequency allows controlling the heating depth and uniformity.