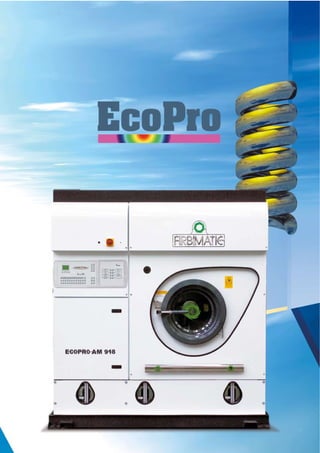

This document provides technical specifications for two dry cleaning machines - the AM918 and AM925. Both machines use a suspended basket and high centrifugal extraction speeds of up to 800 rpm, corresponding to a G-factor of over 300. This allows drying times equal to or less than perchloroethylene machines. The AM series also eliminates the low productivity that previously limited hydrocarbon machine development. Tables provide details on the models' loading capacities, dimensions, motor specifications, and other technical features.