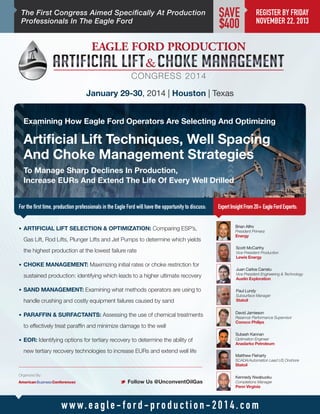

Eagle Ford Production Artificial Lift & Choke Management 2014

- 1. The First Congress Aimed Specifically At Production Professionals In The Eagle Ford SAVE $400 REGISTER BY FRIDAY NOVEMBER 22, 2013 January 29-30, 2014 | Houston | Texas Examining How Eagle Ford Operators Are Selecting And Optimizing Artificial Lift Techniques, Well Spacing And Choke Management Strategies To Manage Sharp Declines In Production, Increase EURs And Extend The Life Of Every Well Drilled For the first time, production professionals in the Eagle Ford will have the opportunity to discuss: • ARTIFICIAL LIFT SELECTION OPTIMIZATION: Comparing ESP’s, Gas Lift, Rod Lifts, Plunger Lifts and Jet Pumps to determine which yields the highest production at the lowest failure rate Expert Insight From 20+ Eagle Ford Experts: Brian Alfro President Primera Energy Scott McCarthy Vice President Production Lewis Energy • CHOKE MANAGEMENT: Maximizing initial rates or choke restriction for sustained production: identifying which leads to a higher ultimate recovery • SAND MANAGEMENT: Examining what methods operators are using to handle crushing and costly equipment failures caused by sand • PARAFFIN SURFACTANTS: Assessing the use of chemical treatments to effectively treat paraffin and minimize damage to the well • EOR: Identifying options for tertiary recovery to determine the ability of new tertiary recovery technologies to increase EURs and extend well life Juan Carlos Carratu Vice President Engineering Technology Austin Exploration Paul Lundy Subsurface Manager Statoil David Jamieson Reservoir Performance Supervisor Conoco Philips Subash Kannan Optimation Engineer Anadarko Petroleum Matthew Fleharty SCADA/Automation Lead US Onshore Statoil Organized By: M Follow Us @UnconventOilGas Kennedy Nwabuoku Completions Manager Penn Virginia w w w. e a g l e - f o r d - p ro d u c t i o n - 2 0 1 4 . c o m

- 2. SAVE $400 Latest reports show that the Eagle Ford is currently producing 1.09 million barrels of oil per day – a staggering number that is even outperforming the Bakken. However, the biggest points of contention surrounding Eagle Ford wells are not how to get them producing large volumes of oil but more critically, how to keep them producing. A recent Wood Mckenzie study shows that most Eagle Ford wells typically drop off between 70 and 80 % in the first year. What is critical to offset these declines and ensure that every well reaches the highest possible net present value, is for Eagle Ford operators to identify the optimal production techniques to increase EURs and extend the life of every well drilled. optimize well spacing to minimize production declines? Studies have shown that choking a well could improve the long-term recovery between 10-15% over a 30-year period – however, what is the optimum choke strategy to employ? How do you tailor choke strategies to specific pressure regimes across Eagle Ford reservoirs? And alongside that, what artificial lift techniques have proven to yield the highest production rates? What are the optimum methods to manage sand and avoid costly equipment failures? How can you The two days will see VP’s, managers and technical experts in Eagle Ford production, discuss the following topics: In light of so many questions and very little available answers, we are delighted to present for the first time ever, The Eagle Ford Production, Artificial Lift and Choke Management Congress 2014, taking place in Houston on January 29 and 30. This is the first congress designed solely for production professionals in Eagle Ford and will be bringing together EP experts from across the play, to examine how Eagle Ford Operators are selecting and optimizing artificial lift techniques, well spacing and choke management strategies to manage sharp declines in production and increase EURs. DAY 1: ARTIFICAL LIFT CHOKE MANAGEMENT Day 1 will start by examining how a leading Eagle Ford operator has designed their primary, secondary and tertiary recovery strategies to directly increase EUR. It will look at how to calculate a reliable inflow Sponsorship And Exhibition Opportunities Available At The Congress Need to generate new sales leads, launch a new product, engage key decision makers, build new future business relationships in key markets, or simply educate the industry about a new product? Then you need to exhibit at the Eagle Ford Artificial Lift Choke Management Congress 2014. Our busy exhibit area is an integral part of the Congress and is of genuine practical value to delegates, who are looking for new solutions and technologies. Exhibiting at the congress will help you position yourself as a market leader and centre of excellence to the key decision makers in the industry. For further information, please contact: info@american-business-conferences.com REGISTER BY FRIDAY NOVEMBER 22, 2013 performance relationship before moving onto several case studies on how operators are selecting between and optimizing different artificial lift techniques such as Rod Pumps, ESPs, Gas Lifts and Plunger Lifts. The discussion will then move to discuss how to tailor choke strategies to different Eagle Ford reservoirs before looking at optimal strategies for controlling sand. DAY 2: CHEMICAL TREATMENT, WELL SPACING EOR Day 2 will start by examining different chemical treatments to effectively treat Paraffin in Eagle Ford wells. It will then discuss the use of automation systems to monitor well sites before exploring the effectiveness of Tertiary recovery methods like Waterfloods and CO2 to extend the life of an Eagle Ford well. The next section will cover well interference and frac hits determining the optimum well spacing to maxmize production. Finally, the two days will conclude with a discussion on identifying optimum strategies for designing and investing in surface infrastructure and will finish with a discussion on how operator’s are handling waste and salt water disposal. Venue Information Eagle Ford Artificial Lift Choke Management Congress 2014 will be held at: The Westin Galleria Houston 5060 West Alabama Houston, Texas 77056 United States Phone: (713) 960-8100 or + (1) 800 721 3915 www.eagle-ford-production-2014.com + (1) 800 721 3915 info@american-business-conferences.com

- 3. Day 1 Wednesday January 29, 2014 8.30 Chair’s Opening Remarks °° Chaired By: Scott McCarthy, VP Production, Lewis Energy KEYNOTE PANEL: ARTIFICIAL LIFT SELECTION 8.40 Examining Key Criteria Used To Dictate Optimal Artificial Lift Techniques For Specific Reservoir Types And Geological Areas In The Eagle Ford °° Using analysis on reservoir quality, pressure distribution and tubing pressure to choose the right artificial technique °° Designing artificial lift specific to the dry gas, retrograde condensate and black oil windows to increase efficiency and optimize run life of the pump °° Comparing different artificial lift methods to determine which yields the highest economic recovery with the lowest failure rate in different areas °° Assessing how cost, durability and failure rate are analyzed to determine most appropriate artificial techniques °° Examining techniques for deciding when to pump, what to pump the curve and for how long to pump Brian Alfaro, President, Primera Energy Juan Carlos Carratu, VP Engineering Technology, Austin Exploration Tom Krawietz, Production Engineering Manager, Murphy Oil Jake Klein, Production Manager, Texas American Resources Gus Vegas, Production Engineer, Carrizo Oil Gas 9.10 Question Answer Session CASE STUDY: ARTIFICIAL LIFT SELECTION 9.20 Examining How An Operator Has Selected The Optimal Artificial Lift Method Based On The Parameters Of Cost, Run Life And Failure Rates °° Assessing how cost, durability and failure rate have been successfully used to select artificial lift technique in the Eagle Ford °° Evaluating how IP rates on past wells have been used to influence artificial lift selection on new wells in close proximity °° Hearing how initial lift performance during the flumping period was used to determine which method delivers with the lowest failure rate during this period °° Observing how well bore conditions should be used to accurately select the appropriate artificial lift technique Joe Becnel, Production Engineering Supervisor, ConocoPhillips 9.50 Question Answer Session 10.00 Morning Refreshments In The Exhibition Area PRODUCTION ECONOMICS 10.30 Planning Flexible Primary Recovery Schemes To Reduce Downtime And Maximize Production Economics For The Full Life Cycle Of The Well • Evaluating strategies for optimizing artificial lift equipment selection, sizing, and design to ensure longevity of the equipment and continued production • Analyzing site logistics and operational management such as automation and crew requirements to determine optimal means of monitoring production to reduce downtime and operational cost • Examining strategies for extending production time between failures and ensuring workovers are being executed properly to save on long term expenditure • Understanding how to develop production facilities and surface infrastructure to maximize production and enable long term field development Subash Kannan, Optimization Engineer, Anadarko Petroleum 11.00 Question Answer Session EAGLE FORD ARTIFICIAL LIFT OPTIMIZATION ARTIFICIAL LIFT CHOKE MANAGMENT Day 1 will examine key criteria used to dictate optimal artificial lift techniques for specific reservoir types, ways of optimizing artificial lift techniques and determining most effective choke strategies for highest recovery DETERMINING THE RIGHT ARTIFICIAL LIFT APPLICATION FOR DIFFERENT GEOLOGICAL WINDOWS AND RESERVOIR TYPES ROD PUMP: CASE STUDY 11.10 Identifying Successful Flow Regimes And Methods For Handling Dog Legs, Slugging And Gas Interference To Increase The Run Time Of A Rod Pump °° Understanding how rod pumps are being operated in the field: are strokes being pumped per minute or are they being left to flow for 3 or 4 days? °° Identifying optimum methods for dealing with slugging and gas interference issues to increase the efficiency of the rod pump °° Examining sand and run time issues on deviated wells to determine ways to prevent wear and tear and shortened tube and rod lives °° Evaluating the maximum angle needed to keep doglegs down and find pumping units and wells °° Using latest results to determine the optimum rod centralizer program to use to increase run time Jason Churchill, Operations Engineering Manager, Venado Oil Gas Bob Harris, Consultant, Venado Oil Gas OIL GAS SEPARATION 11.40 Understanding, Predicting And Managing Down Hole Gas And Liquids Separation To Maximize Returns And Run Operations Efficiently °° Assessing different gas separation technologies and tools being used to prevent gas interference and reduce maintenance costs °° Determining the optimum placement of gas separators in the well to handle high GOR wells °° Identifying any new technologies that have been effective in restraining gas from entering the system and minimize gas ingestion Jason Churchill, Operations Engineering Manager, Venado Oil Gas Bob Harris, Consultant, Venado Oil Gas 11.55 Question Answer Session 12.10 Lunch In Exhibition Area PLUNGER LIFT: CASE STUDY 1.10 Delivering Production Results On A Plunger Lift Application To Determine How Effective They Are In High Condensate Areas Of The Eagle Ford °° Examining the trend in Continuous Flow Plunger for wells containing high levels of gas in order to optimize production. °° Understanding the maximum degrees in which a plunger can work effectively: can they work effectively at 60 or 65 degrees? °° Examining if operators have been able to get pressure up high enough in this condensate field to use a plunger lift applicationIdentifying latest plunger lift technologies to understand if you can perform chemical injections on the same string to treat H2S °° Comparing production results from chemical injections against BAT and Capillers to determine optimal treatment for plunger lifts Cleon Dunham, President, Artificial Lift RD Council ESP: CASE STUDY 1.25 Evaluating Whether The Improvement On Decline Curves, Total Run Life And Failure Rate Justify The Initial Capital Expenditure °° Examining successful applications of ESP in Eagle Ford to determine how successfully they have worked °° Understanding the criteria to use when deciding when to apply an ESP application °° Explaining the lowest volume and maximum amount of gas that an ESP can run on without failing to determine the point at which it can’t be used °° Assessing the technological developments in ESP to avoid gas locks and internal erosion °° Analyzing production performance seen by using dual ESP Systems to understand if they are causing big increments in production °° Examining various tools such as ADV, SandCats and other Tubing String and Pump Tools to enhance the performance of the ESP Cleon Dunham, President, Artificial Lift RD Council 1.40 Question Answer Session GAS LIFT: CASE STUDY 1.50 Assessing IP Rates, Run Times And Failure Rates Of Gas Lift To Determine If The Incremental Production Justifies The Initial Infrastructure Costs °° Considering the availability of surface infrastructure and space needed to run a gas lift to determine to accessibility of this application °° Calculating the cost of the gas source, compression equipment pipeline to assess the economics of using this method °° Outlining how an operator is removing H2S from gas to use for gas lift °° Examining results of using centralized compression vs. pad compression to determine the most economic method for extending the life of the wells °° Uncovering new technologies with the potential to make gas lift cheaper or more productive 2.20 Question Answer Session 2.30 Afternoon Refreshments In Exhibition Area CHOKE STRATEGIES 3.00 Understanding How To Tailor Choke Strategies To Specific Pressure Regimes Across Eagle Ford Reservoirs To Optimize Draw Down Rate °° Examining how to tailor choke strategies to varying reservoir types and pressures to avoid damaging the formation °° Drawing down wells: how are they dropping the pressure over a period and how are they drawing that out? °° Identifying which leads to higher ultimate recovery: maximum initial rates or restricting chokes for flatter, more sustained production °° Determining a stable choke setting to ensure a stable flow regime, avoid killing wells and produce as much oil as possible °° Assessing how an operator is designing facilities to handle large fluctuations in flow rate with minimal damage to equipment David Jamieson, Reservoir Performance Supervisor, ConocoPhillips 3.30 Question Answer Session SAND MANAGEMENTEXAMINING STRATEGIES FOR CONTROLLING SAND TO REDUCE DAMAGE TO SURFACE EQUIPMENT AND PREVENT COSTLY WORKOVERS CRUSHING SAND MANAGEMENT 3.40 Determining Whether Resin Coated Or Synthetic Proppants Can Be Justified Over White Sand And Optimal Methods To Remove Sand And Avoid Costly Equipment Failures °° Assessing a case of embedment to determine the point at which the sand grains start to break down and crush °° Understanding what methods an operator is using to monitor the formation and identify when crushing is occurring: at what point do you interfere? °° Analyzing results from initial flow backs to understand the types of equipment failures operators are experiencing due to sand °° Strategies from preventing sands from causing trouble at pumps to avoid any impact to the productivity of the well °° Examining how operators are mitigating sand in their flow stream to prevent equipment tear °° Evaluating the costs involved in upgrading equipment to improve sand handling to derive if it would be more economical to change frack design 4.25 Question Answer Session 4.35 Chair’s Closing Remarks 4.45 - 5.45 Networking Drinks Reception In Exhibition Area www.eagle-ford-production-2014.com + (1) 800 721 3915 info@american-business-conferences.com

- 4. Day 2 Thursday January 30, 2014 8.30 Chair’s Opening Remarks °° Chaired By: Scott McCarthy, VP Production, Lewis Energy KEYNOTE PANEL : EUR PRODUCTION 8.40 How Eagle Ford Operators Have Designed Primary, Secondary And Tertiary Recovery Strategies To Directly Increase EUR °° Quantifying decline rates to predict projected well life °° Observing how well bore conditions should be used to accurately select the appropriate artificial lift technique °° Outlining the criteria used to design and budget for wellbore materials and equipment for secondary and tertiary recovery in advance °° Determining how far in advance operators plan their choke strategies to maximize EUR Frank Starr, CEO, Crimson Energy Partners 9.10 Question Answer Session CHEMICAL TREATMENTS PARAFFIN CONTROL AND SURFACTANTSASSESSING CHEMICAL TREATMENTS TO MITIGATE PARAFFIN AND INCREASE OIL RECOVERY PARAFFIN CONTROL 9.20 Identifying Optimal Techniques For Paraffin Control To Prevent Reduced Oil Production As A Result Of Plugging °° Understanding the root causes of paraffin problems to identify when and where they might occur °° Examining the detrimental effects of paraffin to production operations to determine how quickly it needs to be dealt with °° Identifying what treatment has been used to successfully increase the production of a well that has been under-performing °° Monitoring methods (e.g. mapping temperatures) to identify the high-risk areas and optimize paraffin treatment programs Patrick Shuler, Oil Field Chemist, PEERI SURFACTANTS 9.40 Examining How Oil Production Can Be Enhanced Through The Use Of Surfactant Technologies °° Assessing mechanisms for increased oil recovery via surfactant technology °° Evaluating surfactants included in frac fluids to increase chemical contact and oil recovery °° Understanding the side-effects of surfactants to prevent any undesirable effectsIdentifying other enhancements seen from the use of surfactants to justify investment in surfactant technologies Patrick Shuler, Oil Field Chemist, PEERI 10.00 Question Answer Session 10.10 Morning Refreshments In Exhibition Area AUTOMATION EXAMINING DIFFERENT TECHNIQUES FOR ACQUIRING WELL DATA TO MONITOR WELLSITES REMOTELY COMMUNICATION AUTOMATION 10.40 Evaluating The Use Of Automation Systems To Effectively Acquire Data And Monitor Well sites Effectively From A Remote Location °° Assessing the automation system an operator is using to acquire data and the method they are using to collate the production data they are getting °° Understanding the extent to which companies are able to configure wells remotely to determine how they control shut ins and bring new pumps on °° Evaluating the ability to successfully monitor wells and diagnose issues quickly and effectively to minimize operational costs °° Highlighting potential room for error to determine the reliability of automated systems in handling larger production volumes CHEMICAL TREATMENT, WELL SPACING EOR Day 2 will examine how operators are using chemical treatments to treat H2S and Paraffin, determine the optimal well spacing, criteria for identifying optimum EOR regimes and will finish with a discuss on optimizing surface facilities and water disposal Matthew Fleharty, SCADA/Automation - US Onshore, Statoil 11.10 Question Answer Session WELL INTERFERENCE: WELL SPACING FRAC HITS DETERMINING THE OPTIMUM SPACING TO MANAGE STEEPER PRODUCTION DECLINES RESULTING FROM HIGH WELL DENSITY AREAS WELL SPACING 11.20 Determining The Optimum Well Spacing To Maximize Production Whilst Minimizing Interference °° Assessing the accuracy of different simulation models in determining which well spacing will lead to highest economic recoveryIdentifying the key techniques being used to determining the correct well spacing for optimum recovery °° Balancing capital expenditure against well spacing to identify the point at which an operator can produce the most oil from the least amount of wells °° Determining the optimum down spacing to minimize well interference and ensure wells are not competing for same reserves Paul Lundy, Subsurface Manager, Statoil 11.50 Question Answer Session 12.00 Lunch In Exhibition Area FRAC HITS 1.00 Examining How Operators Are Mitigating Frac Hits From Off Set Wells And Handling Them Once They Have Occurred To Minimize Loss To Production °° Examining processes in place to identify wells that could be off set wells °° Assessing how operators are recovering the well once frac hits have occurred and the well has lost a significant portion of its production °° Scrutinizing the relationship between frac hits and well interference to infer if a correlation can be made from micro-seismic analysis to production °° Assessing results from rate transient analysis on recent wells to gain insight into the drainage patterns and interference Kennedy Nwabuoku, Completions Manager, Penn Virginia Corporation 1.30 Question Answer Session EOR INCREASING THE VALUE OF A WELL THROUGH TERTIARY RECOVERY: ASSESSING THE EFFECTIVENESS OF WATERFLOODS AND CO2 IN ENHANCING ULTIMATE RECOVERY WATERFLOOD CO2 1.40 Examining The Challenges Of Enhancing The Recovery Of Shale Oil Wells And Predicting Their Performance To Plan For Tertiary Recovery °° Presenting the decline analysis results for 40 oil producing wells in Eagle Ford to determine when waterfloods are needed °° Discussing the hyperbolic decline with b1 to understand how this enhances ultimate recovery °° Presenting simulation results for CO2 Flooding to ascertain the viability of its use in Eagle Ford wells °° Assessing the effect of different parameters on EUR to identify the key parameters affecting the simulation results Mohabbat Ahmadi, Professor, University Of Alaska Fairbanks 2.10 Question Answer Session PANEL: WATERFLOOD CO2 2.20 Scrutinizing Water Flooding And CO2 Technologies To Determine Their Effectiveness In Extending The Life Of An Eagle Ford Well °° Analyzing latest production results from Water flood pilots to determine the percentile increase seen in EURs from tertiary recovery °° Assessing the cost vs. recovery increase as a result of CO2 Flooding to determine the commercial feasibility of using it on Eagle Ford wells °° Deducing the direction the industry is going to be taking for tertiary recovery to understand which method to undertake °° Identifying any other potential tertiary recovery options and the criteria used to determine the optimum method to employ Scott McCarthy, VP Production, Lewis Energy Paul Lundy, Subsurface Manager, Statoil Patrick Shuler, Oil Field Chemist, PEERI Cleon Dunham, President, Artificial Lift RD Council 2.50 Afternoon Refreshments In The Exhibition Area SURFACE INFRASTRUCTURE: CONDENSATE STABILIZATION ELECTRICITY AVAILABILITY EXAMINING HOW OPERATORS ARE EFFECTIVELY DESIGNING SURFACE INFRASTRUCTURE AND PRODUCTION FACILITIES TO DRIVE DOWN COST PER BARREL SURFACE INFRASTRUCTURE 3.20 Identifying Optimum Strategies For Designing And Investing In Surface Infrastructure To Facilitate Long-Term Field Development °° Condensate Stabilization: examining how an operator is designing and installing their production facilities to facilitate condensate stabilization °° Condensate Stabilization: do incremental production volumes as a result of installing a condensate stabilizer justify the costs °° Electricity Availability: outlining the electrical transmission, distribution and power generation considerations that go into facilities design °° Electricity Availability: Analyzing the best way to work with co-ops and power companies to ensure well sites get hooked up to a power supply Ross Magee, Facilities Engineering Project Manager, Marathon Oil 3.50 Question Answer Session WASTE WATER DISPOSAL IDENTIFYING OPTIMAL STRATEGIES FOR THE DISPOSAL OF WASTE WATER ECONOMICALLY IN THE EAGLE FORD WASTE WATER DISPOSAL 4.00 Examining How Operators Are Handling Waste And Salt-Water Disposal To Remain Compliant With Regulations °° Understanding how operators are cost-effectively handling waste water disposal in large volumes °° Identifying if an operator has been able to successfully implement an economic recycling system to reduce long-term costs °° Providing a cost-benefit analysis of disposal vs. reinjection to determine the optimal disposal method for waste water in the Eagle Ford °° Identifying the benefits of using digging pits to recycle salt waterUnderstanding if operators are using line pits to manage their salt-water production Cliff Davis, Production Engineer, Primera Energy 4.30 Question Answer Session 4.40 Chair’s Closing Remarks And End Of Conference “Good diversity in topics and speakers” CONOCOPHILLIPS “Relevant subject with high quality speakers” TALISMAN ENERGY INC “Useful content and discussions” CHEVRON www.eagle-ford-production-2014.com + (1) 800 721 3915 info@american-business-conferences.com

- 5. Yes P I would like to register the delegate(s) below for the 2 day conference Eagle Ford Artificial Lift Choke Management Congress 2014 Details PLEASE USE CAPITALS - PHOTOCOPY FOR MULTIPLE DELEGATES Delegate 1 Delegate 2 * Mr * Mr * Dr * Miss * Ms * Mrs * Other: * Dr * Miss * Ms * Mrs * Other: Name Name Position Position Organization Organization Email Email Telephone Telephone Address For Invoice Purposes WE HAVE GROUP DISCOUNTS Zip/Postal Code So you can involve your whole team Country Call for rates: (1) 800 721 3915 Delegate Rates GUESTS ARE RESPONSIBLE FOR THEIR OWN TRAVEL AND ACCOMMODATION ARRANGEMENTS Super Early Booking Discount Early Booking Discount Standard Rate Book And Pay By Friday November 22, 2013 Book And Pay By Friday December 6, 2013 From December 7, 2013 * $1399 USD SAVE $400 * $1599 USD SAVE $200 * $1799 USD 2 Day Conference Pass Add Audio Materials * $299 USD All prices quoted above are inclusive of GST Payment PLEASE TICK APPROPRIATE BOXES AND COMPLETE DETAILS Payment must be received in full prior to the event. * 1. CREDIT CARD Option Please charge my * VISA * AMERICAN EXPRESS Amount $ USD Expiry date Card number Security Code / CVV (required) Name on card * MASTERCARD Signature of card holder * 2. INVOICE Option An invoice containing payment instructions will be sent electronically upon receipt of the completed registration form. How To Finalize Your Registration Terms Conditions The conference is being organized by American Business Conferences, a division of London Business Conferences Ltd, a limited liability company formed under English company law and registered in the UK no. 5090859. Cancellations received 30 days prior to the start of the event will be eligible for a refund less $150 administration fee, after this point no refund will be given. Cancellations must be made in writing, if you are unable to attend you may nominate a colleague to attend in your place at no additional cost. Receipt of this registration form, inclusive or exclusive of payment constitutes formal agreement to attend and acceptance of the terms and conditions stated. All outstanding fees must be paid within our standard payment period of 7 days. Any outstanding invoices will remain valid should cancellation of attendance be received outside of the aforementioned cancellation period. *If you are claiming the early booking discount this may not be used in conjunction with other discounts advertised elsewhere. All discount codes and offers must be claimed at the time of registration. American Business Conferences reserves the right to alter or cancel the speakers or program. American Business Conferences reserve the right to refuse admission. We would like to keep you informed of other American Business Conferences products and services. This will be carried out in accordance with the Data Protection Act. Please write to the Head of Marketing, American Business Conferences at the address below if you specifically do not want to receive this information. American Business Conferences. City Center One. 800 Town Country Blvd. Suite 300. Houston. Texas. 77024 American Business Conferences will not accept liability for any individual transport delays and in such circumstances the normal cancellation restrictions apply. American Business Conferences is a Division of London Business Conferences Limited, Registered in England No. 5090859 EIN. no: 98-0514924 Now that your details are completed please send your registration form to our Customer Service Team using one of the following options: Option 1. Email: info@american-business-conferences.com Option 2. Fax: (1) 800 714 1359 Enquiries And More Information Should you have any enquiries or if you would like to request more information please contact our friendly Customer Service Team on (1) 800 721 3915 or visit the conference website at www.eagle-fordproduction-2014.com www.eagle-ford-production-2014.com + (1) 800 721 3915 info@american-business-conferences.com