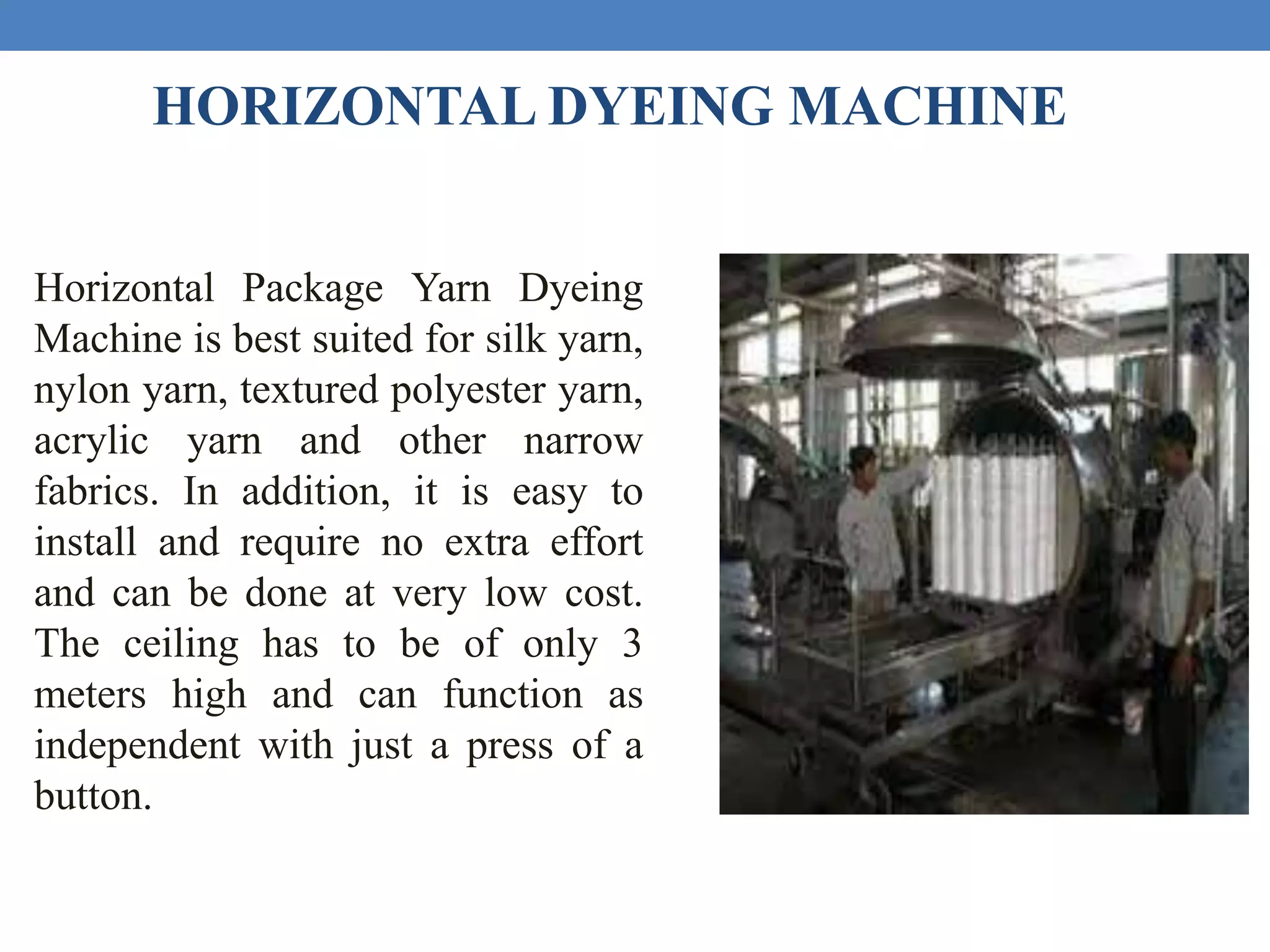

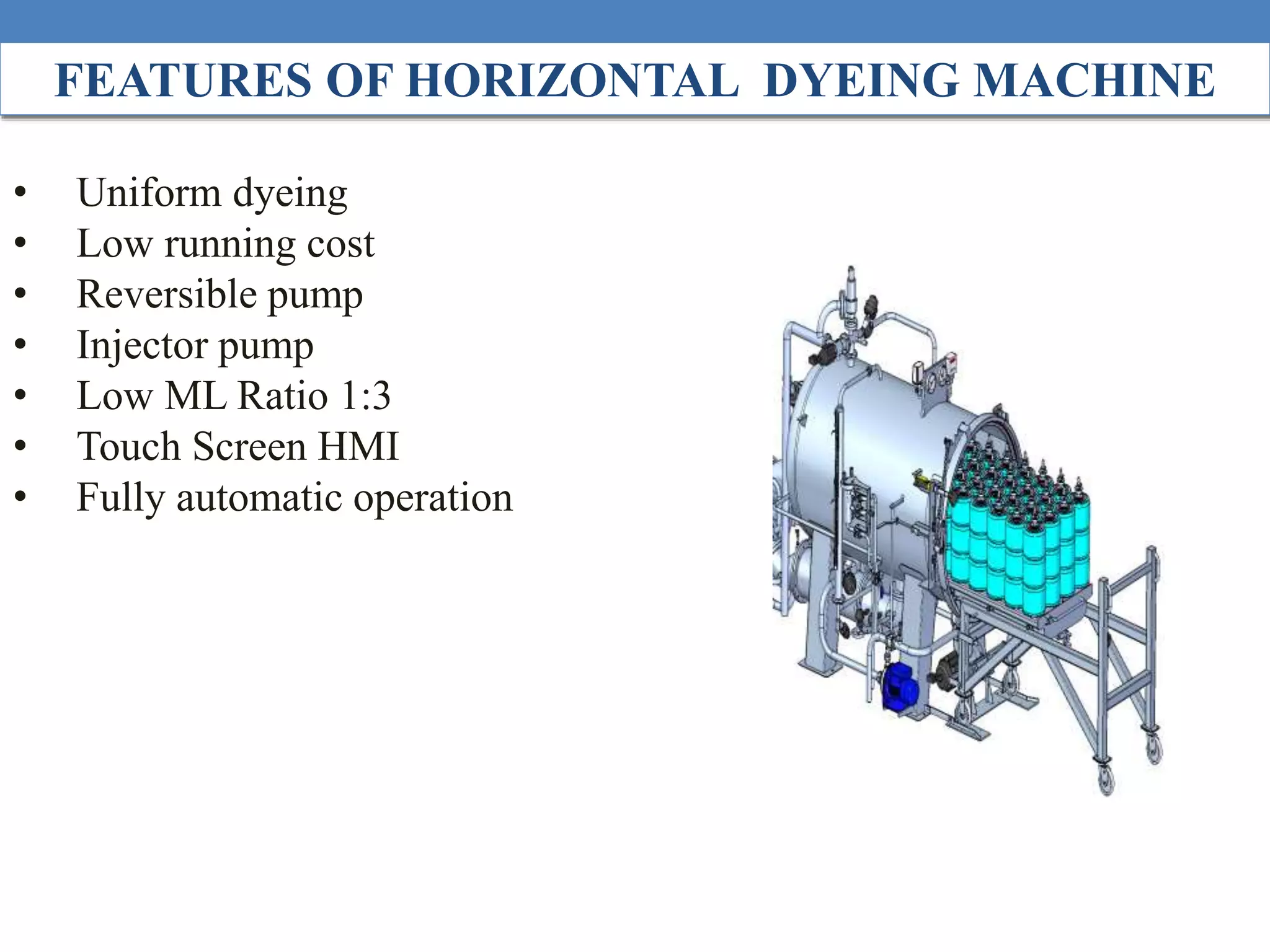

This document discusses various machines used for yarn wet processing. It describes the different steps in wet processing as pretreatment, coloration, and finishing. It focuses on types of yarn dyeing machines like skein dyeing, package dyeing using vertical and horizontal kier machines, and beam dyeing. Specific machines are described in detail like vertical and horizontal package dyeing machines, hank dyeing machines, and beam dyeing machines. Their features, advantages, and working mechanisms are explained.