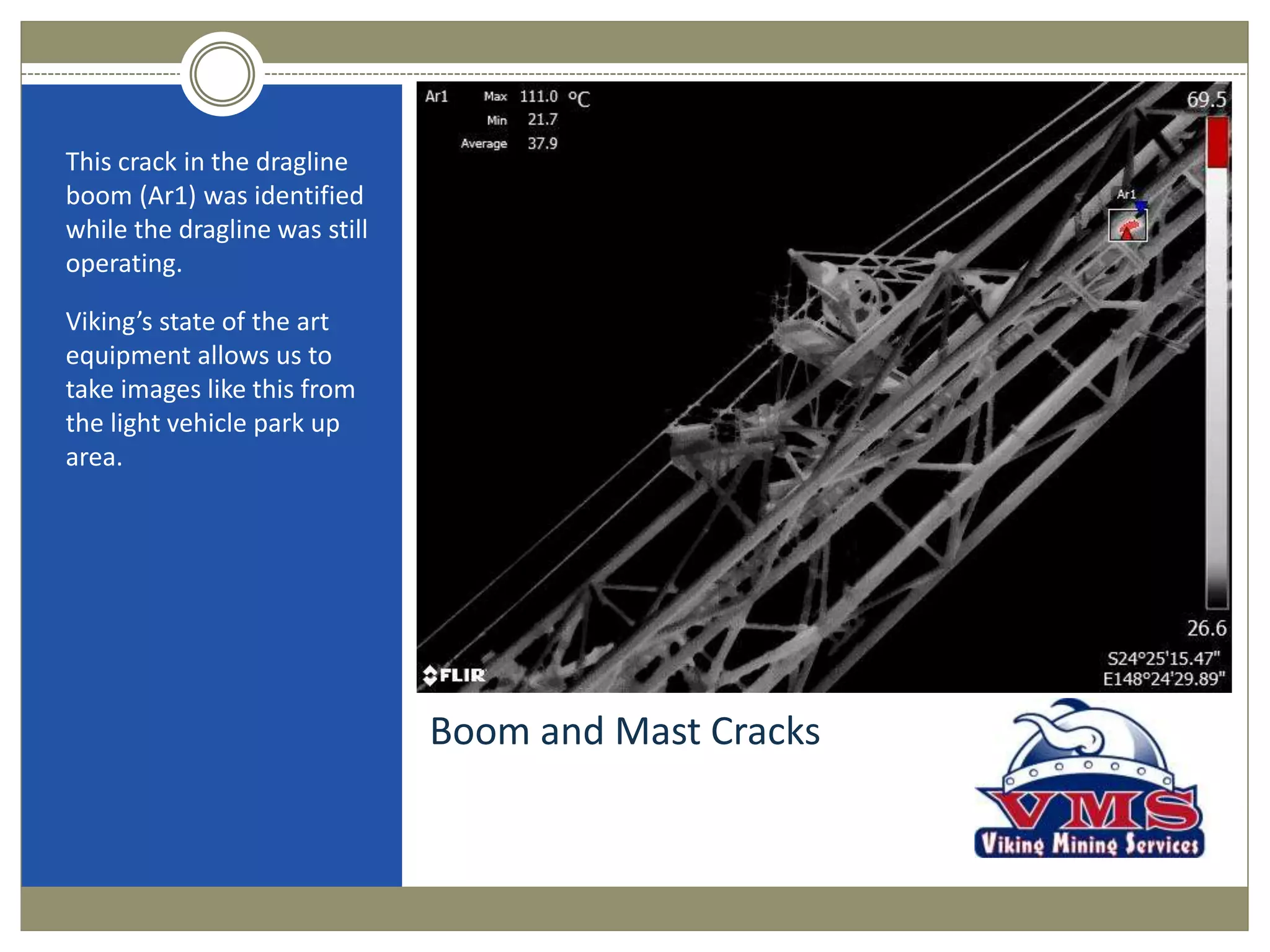

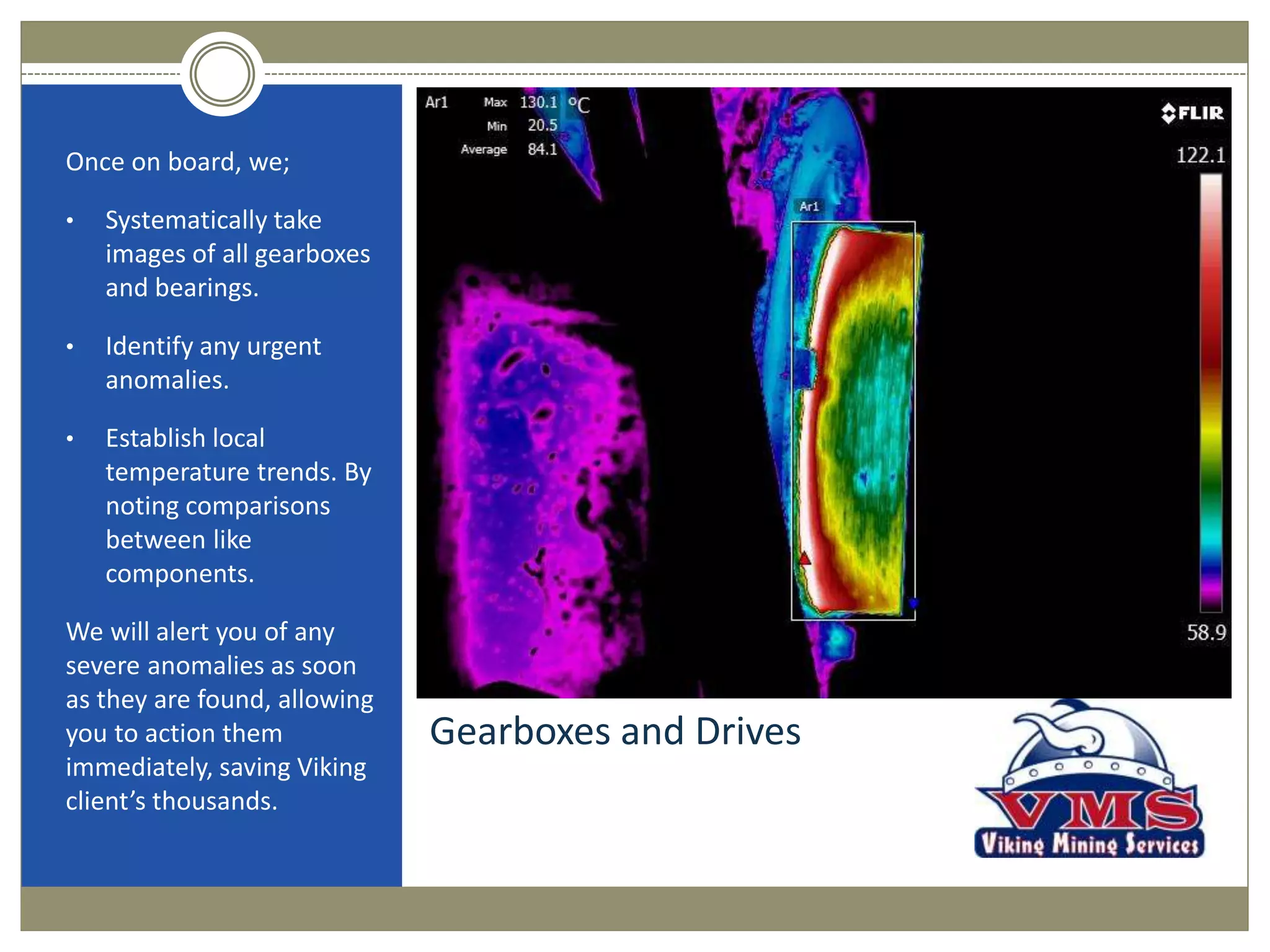

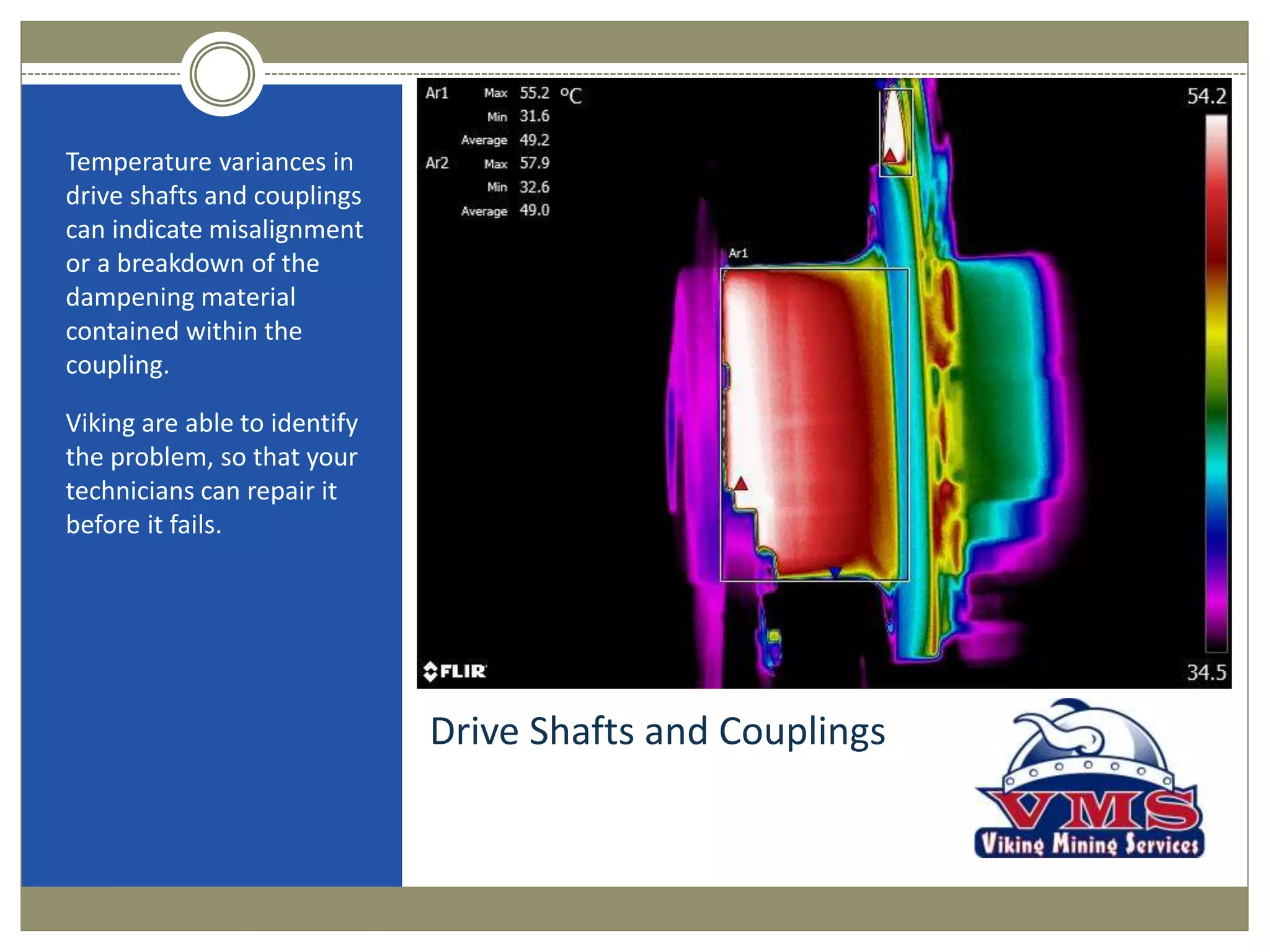

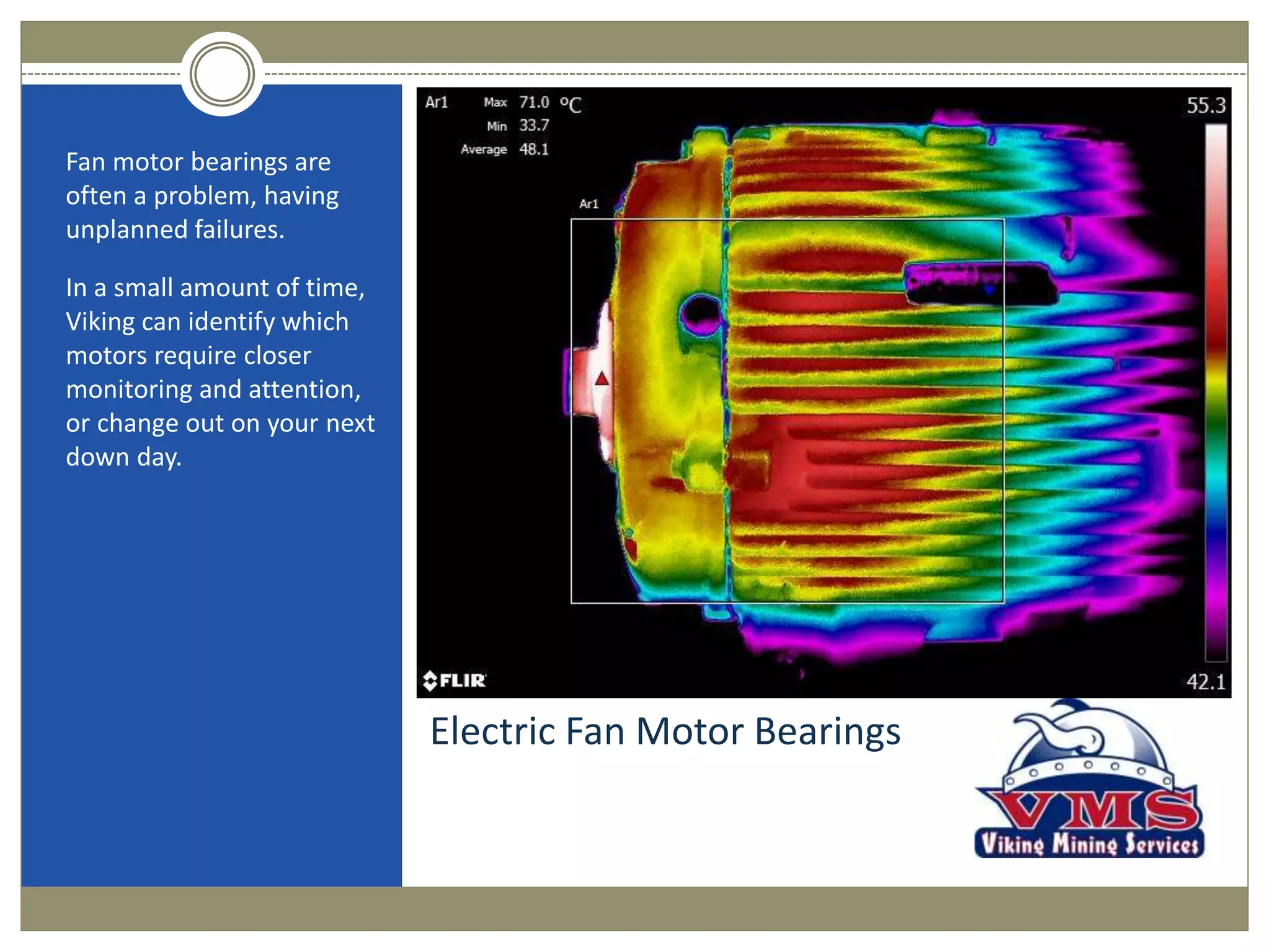

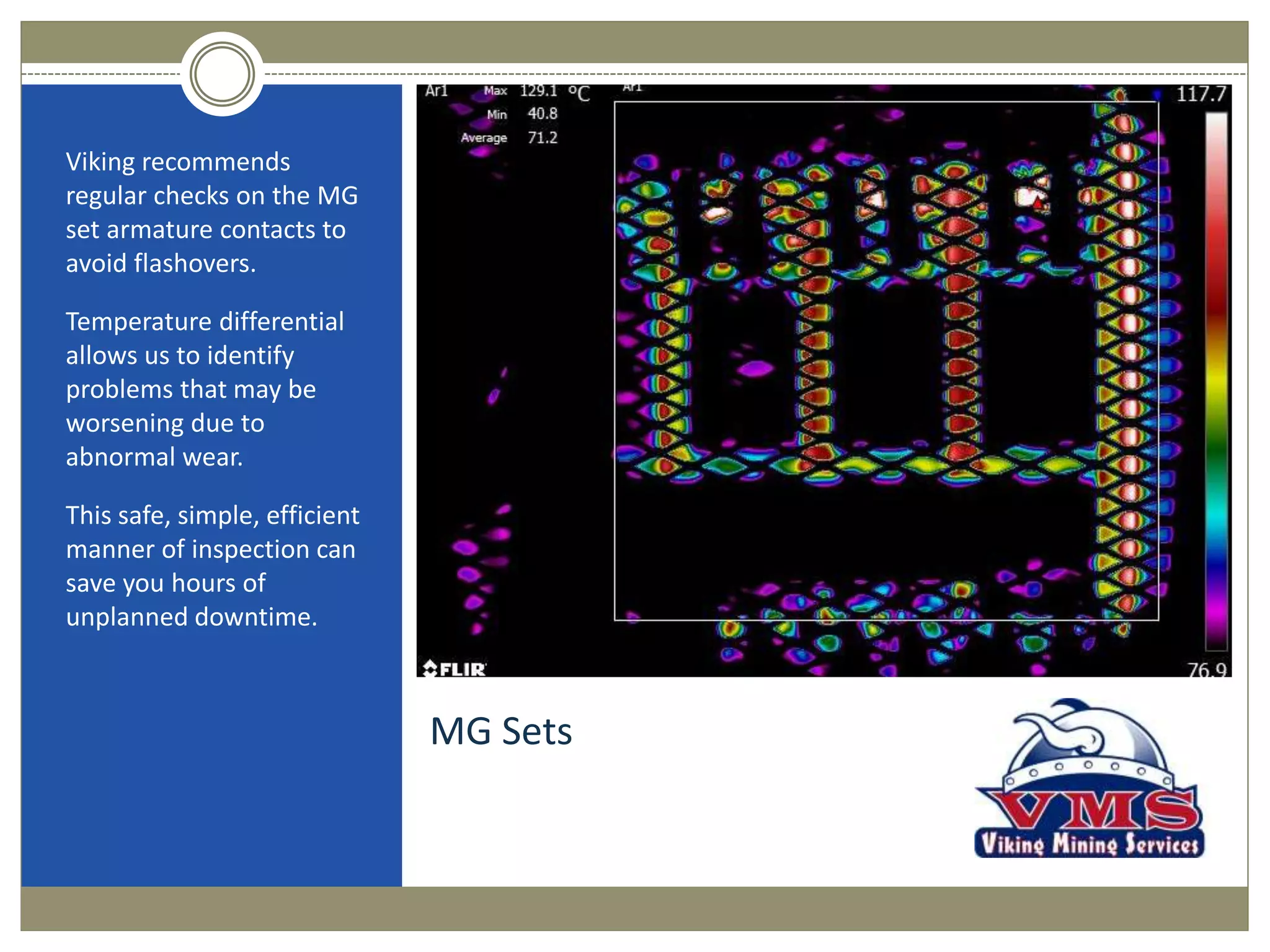

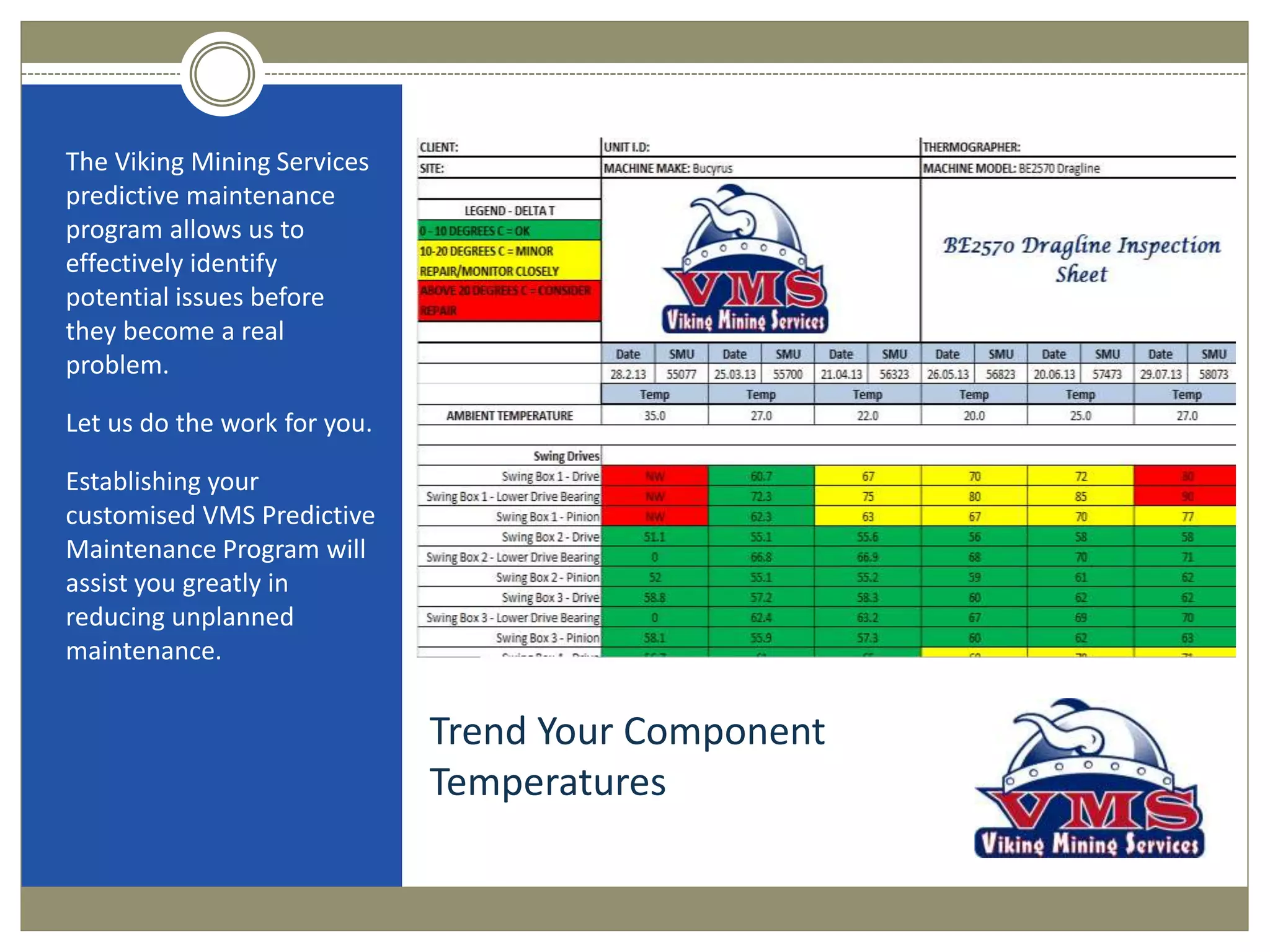

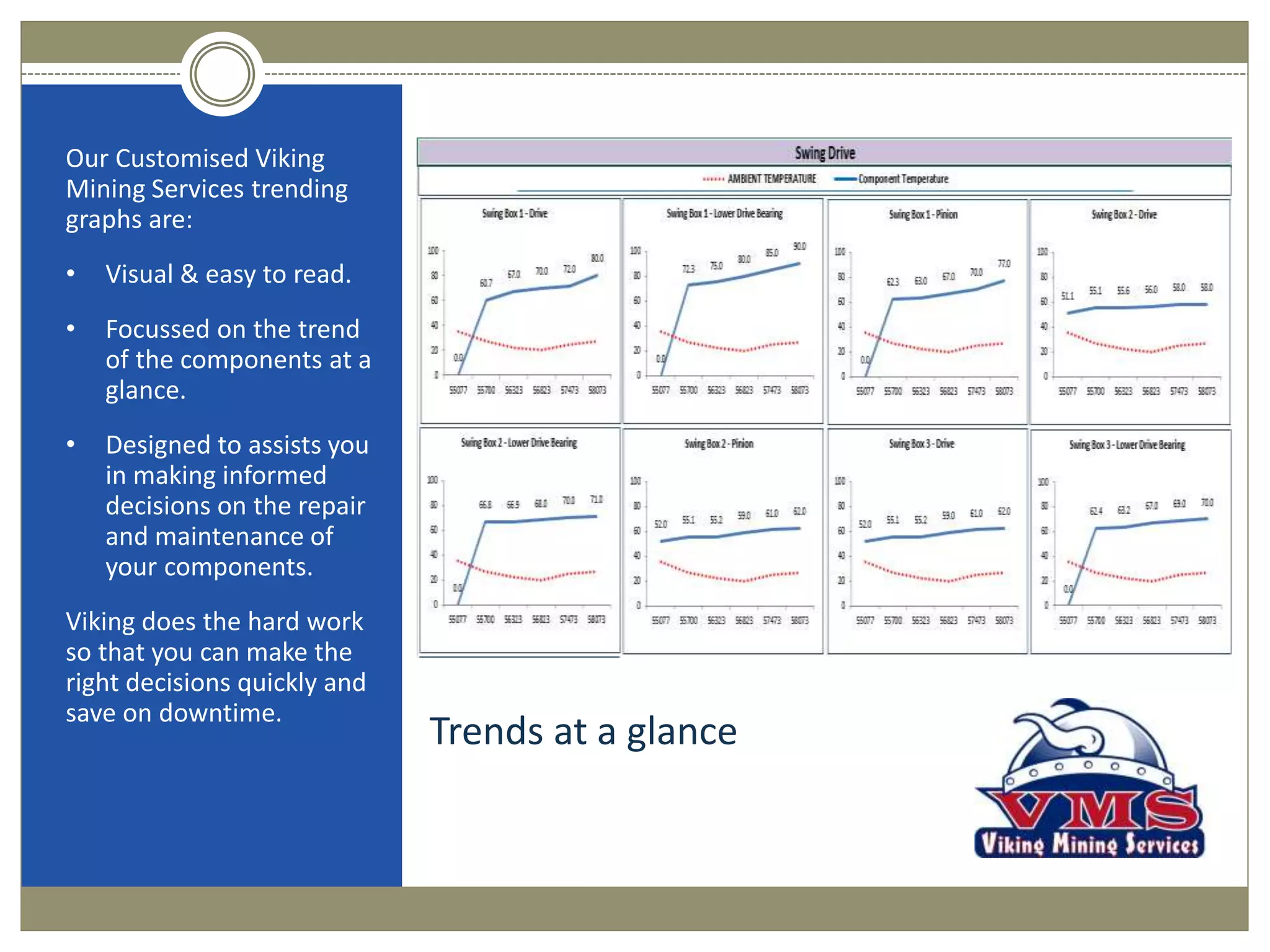

Viking Mining Services provides dragline thermography inspection services to identify potential issues before they cause costly downtime. Using advanced thermography equipment, Viking can inspect areas like booms, masts, gearboxes, bearings, drive shafts, couplings, electric motors, and MG sets to detect cracks, lubrication faults, misalignments, and other anomalies. Viking's inspections help clients establish customized predictive maintenance programs to monitor component trends over time and make informed decisions to schedule repairs and avoid unexpected breakdowns. This proactive approach has saved Viking's customers thousands of dollars in avoided downtime costs.