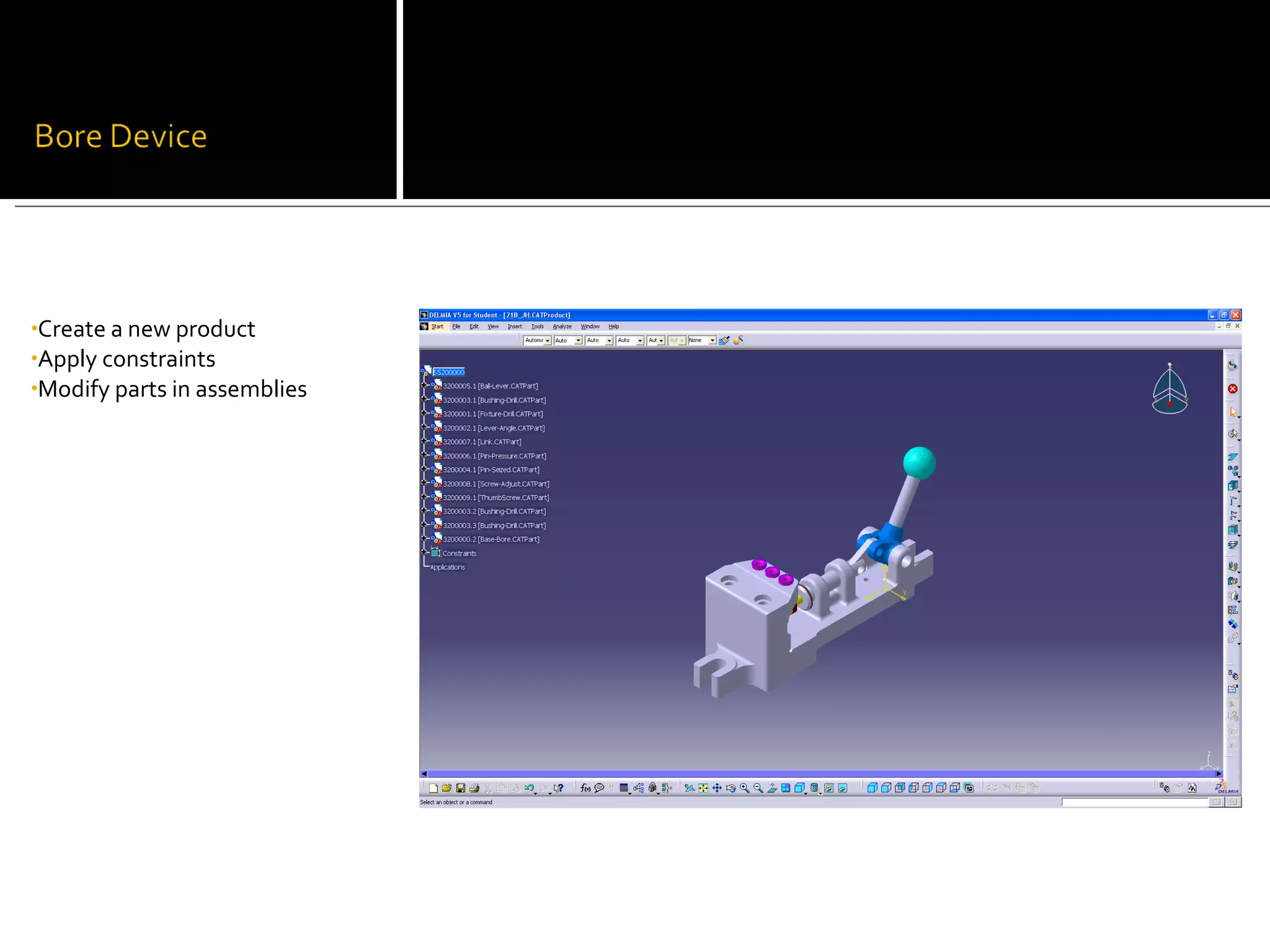

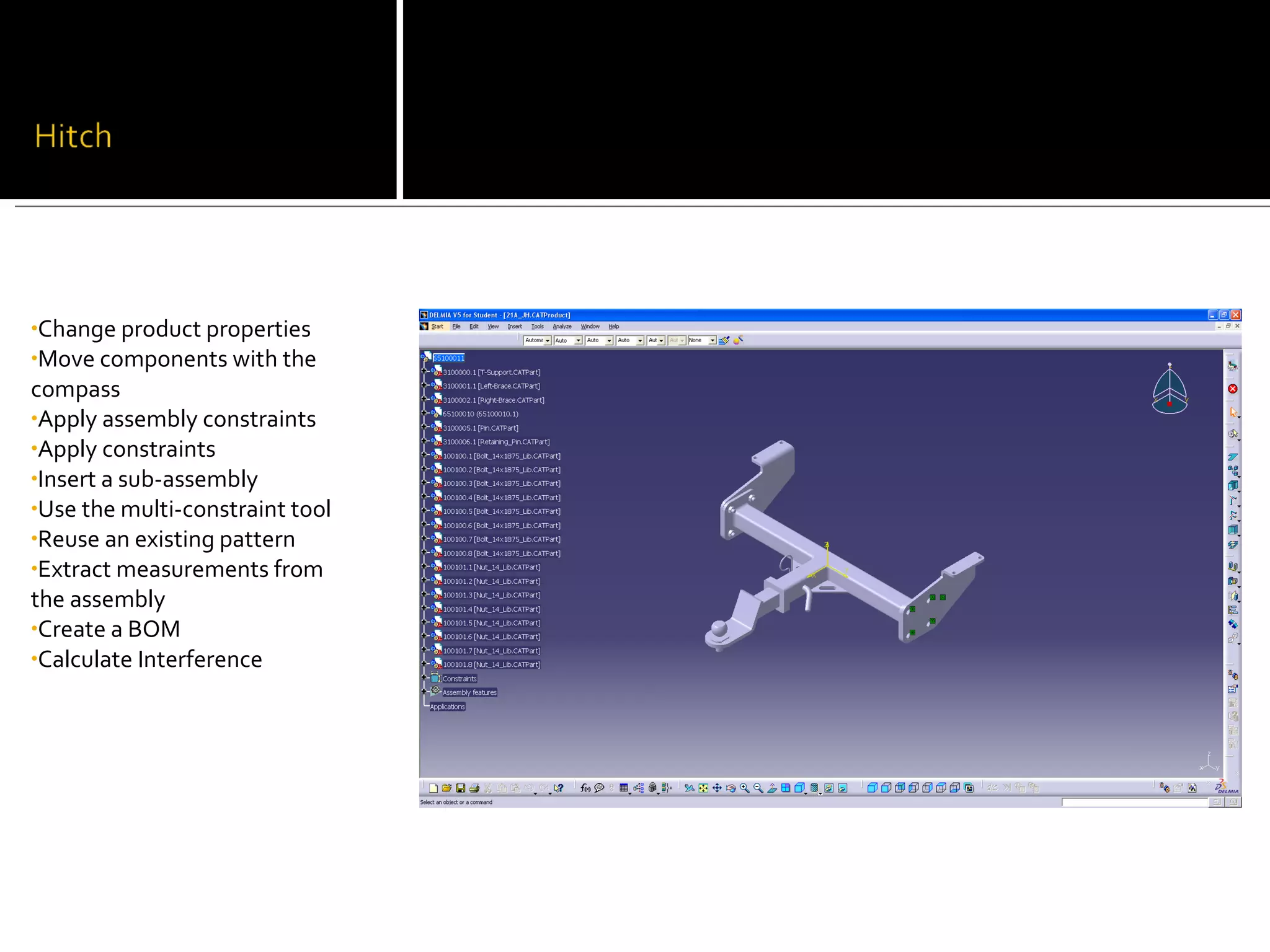

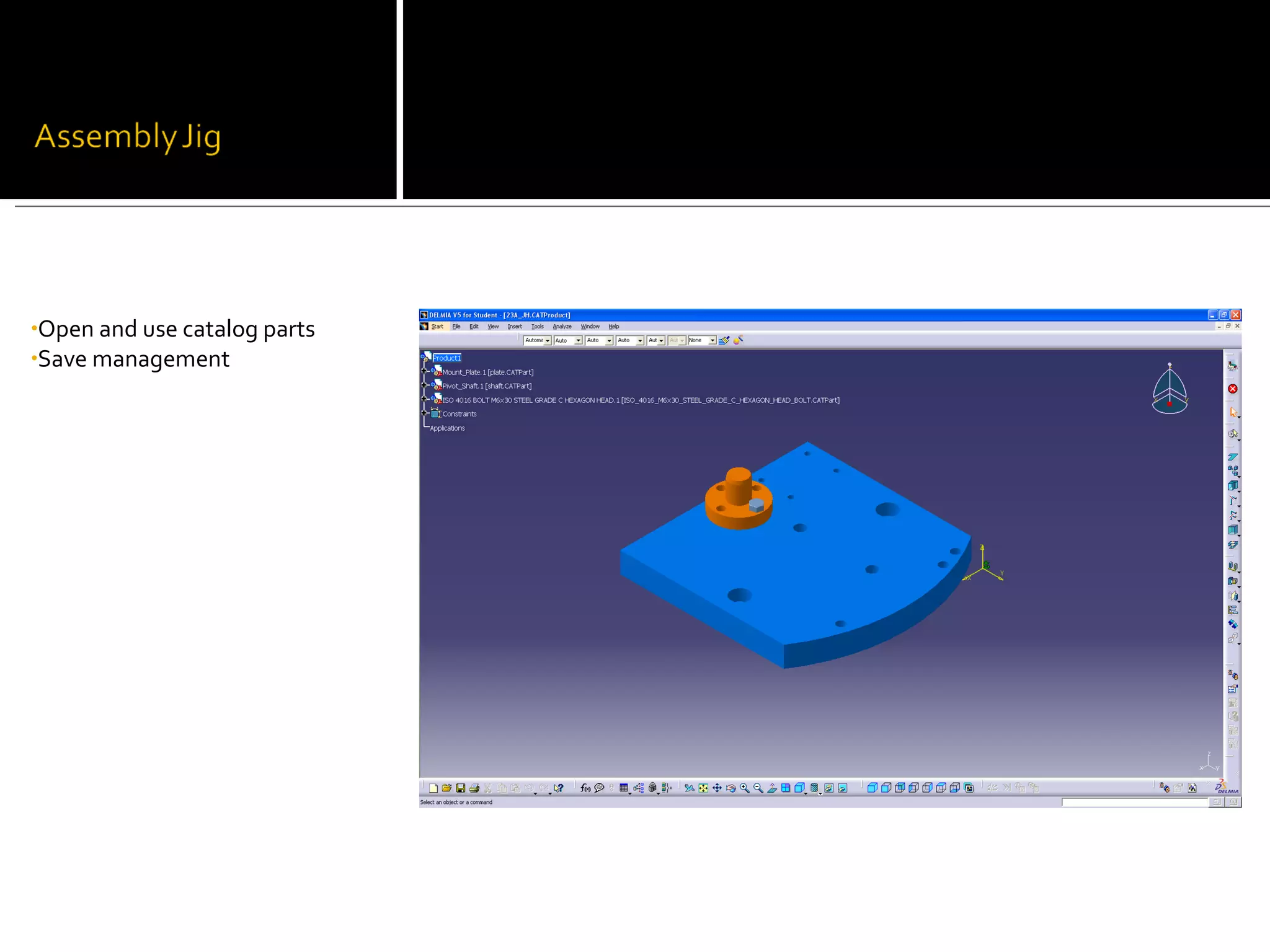

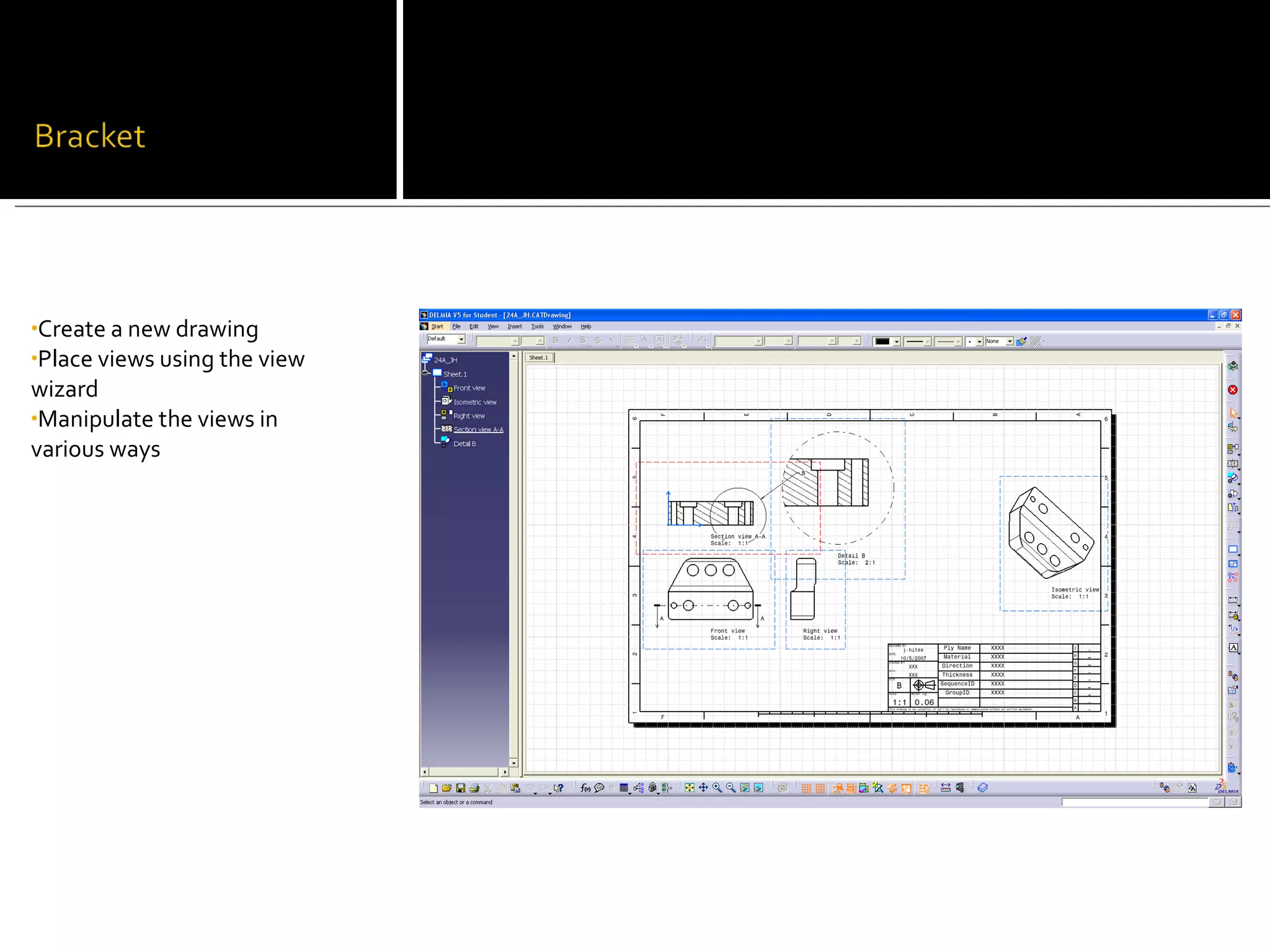

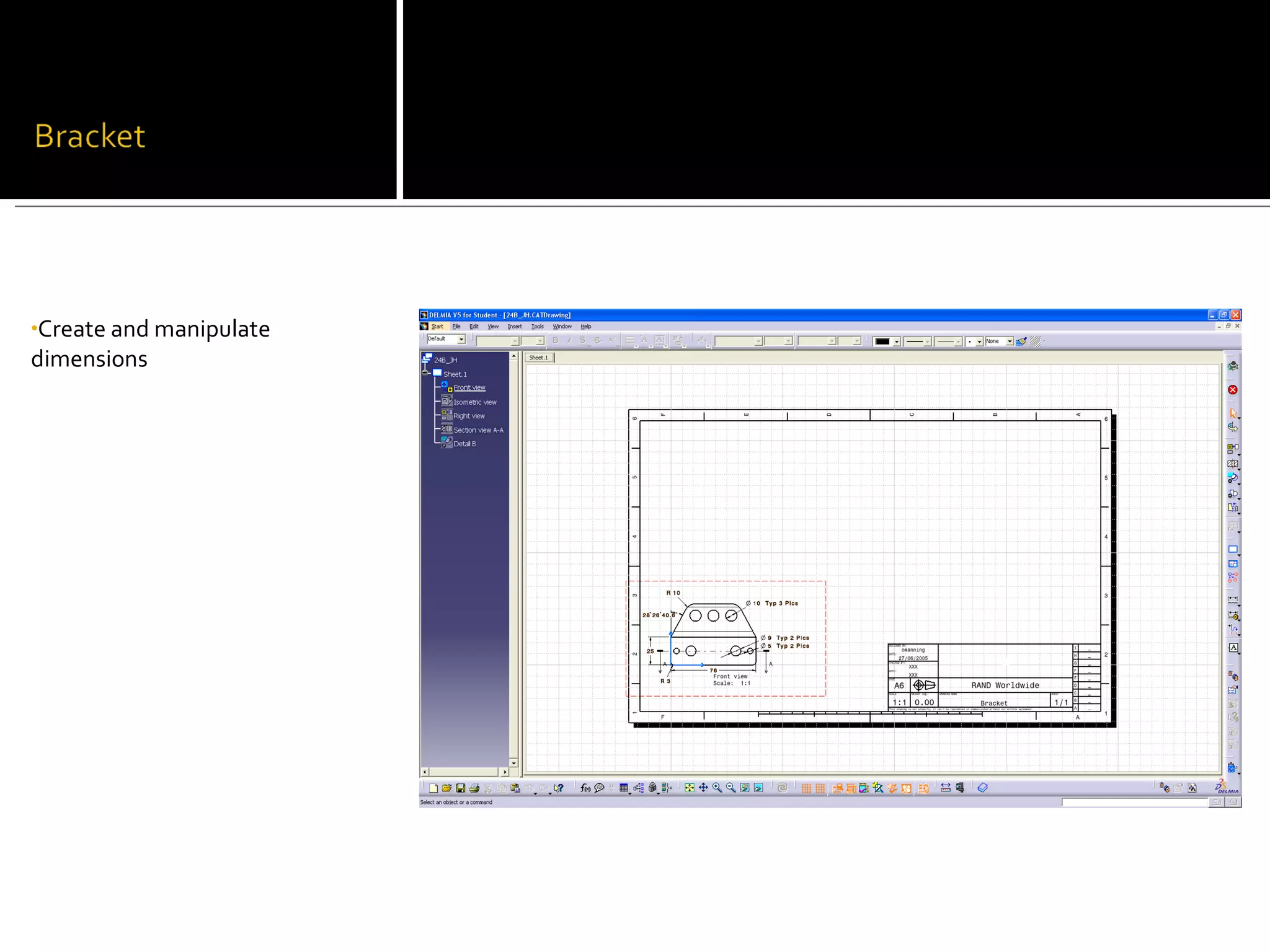

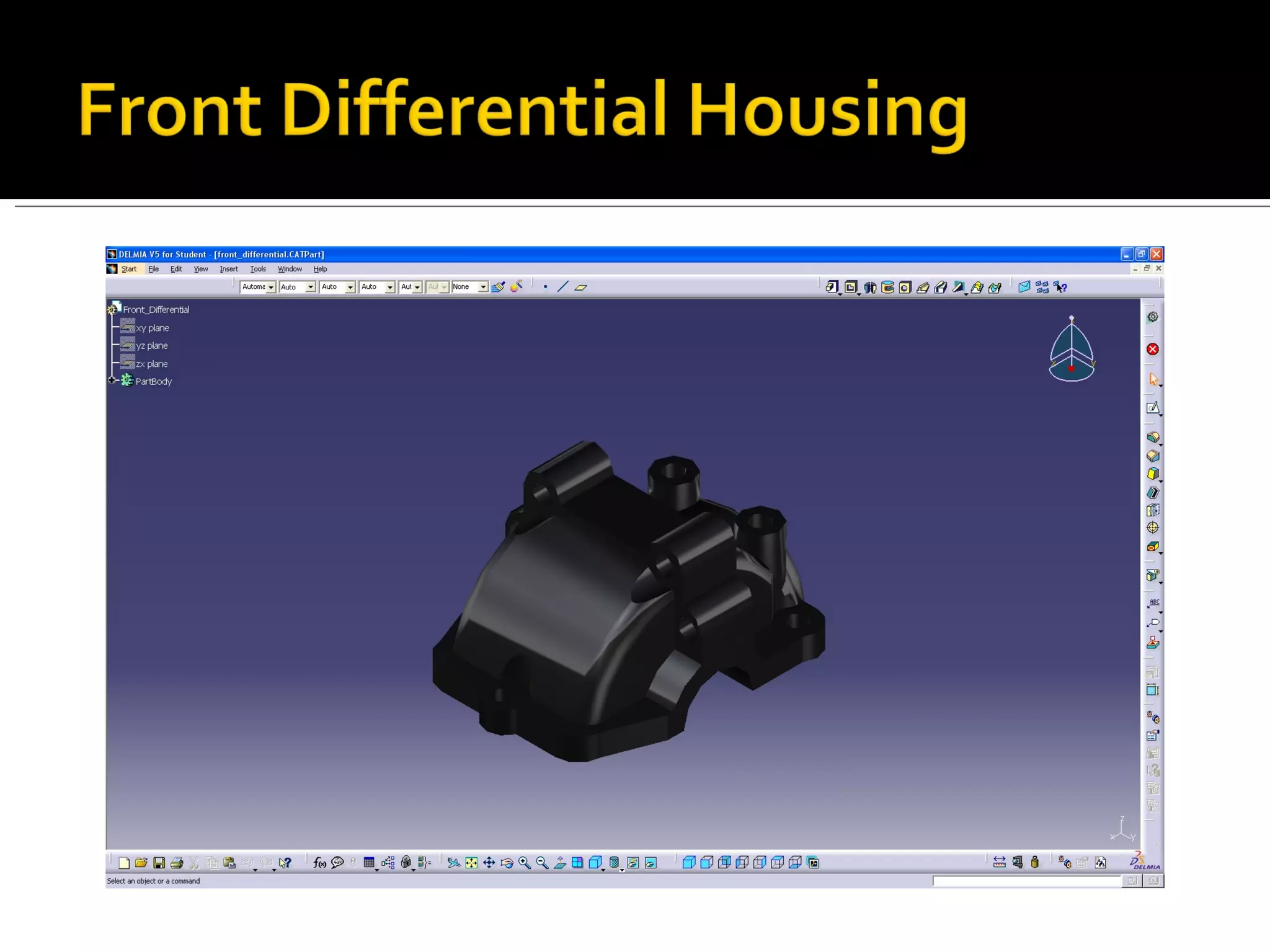

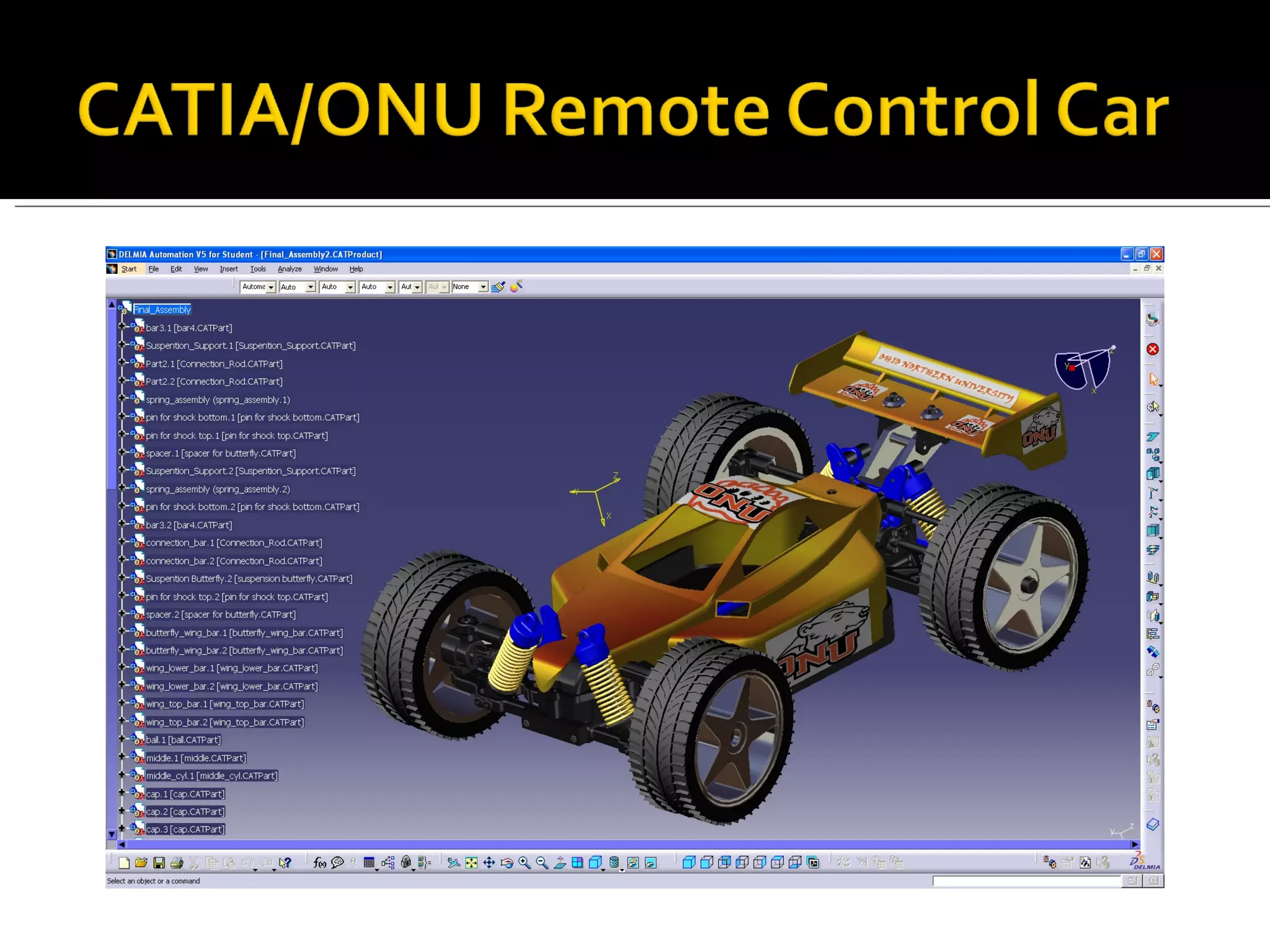

This document outlines a course on design of 3D CAD solid models for mechanical parts and products. It will cover creating sketches and 3D solid models in CATIA, building models from reference elements, creating drawings from solid models, and understanding parametric and solid modeling. Students will also learn about digital manufacturing applications like CAD, PLM, manufacturing simulation, and VR modeling to gain an understanding of how modern companies utilize these tools. Key skills covered include creating and modifying parts and assemblies, applying constraints, inserting sub-assemblies, creating drawings and dimensions, and using catalog parts and save management. The student providing feedback notes strengths of being able to work at their own pace and outside of class in a light-hearted environment.