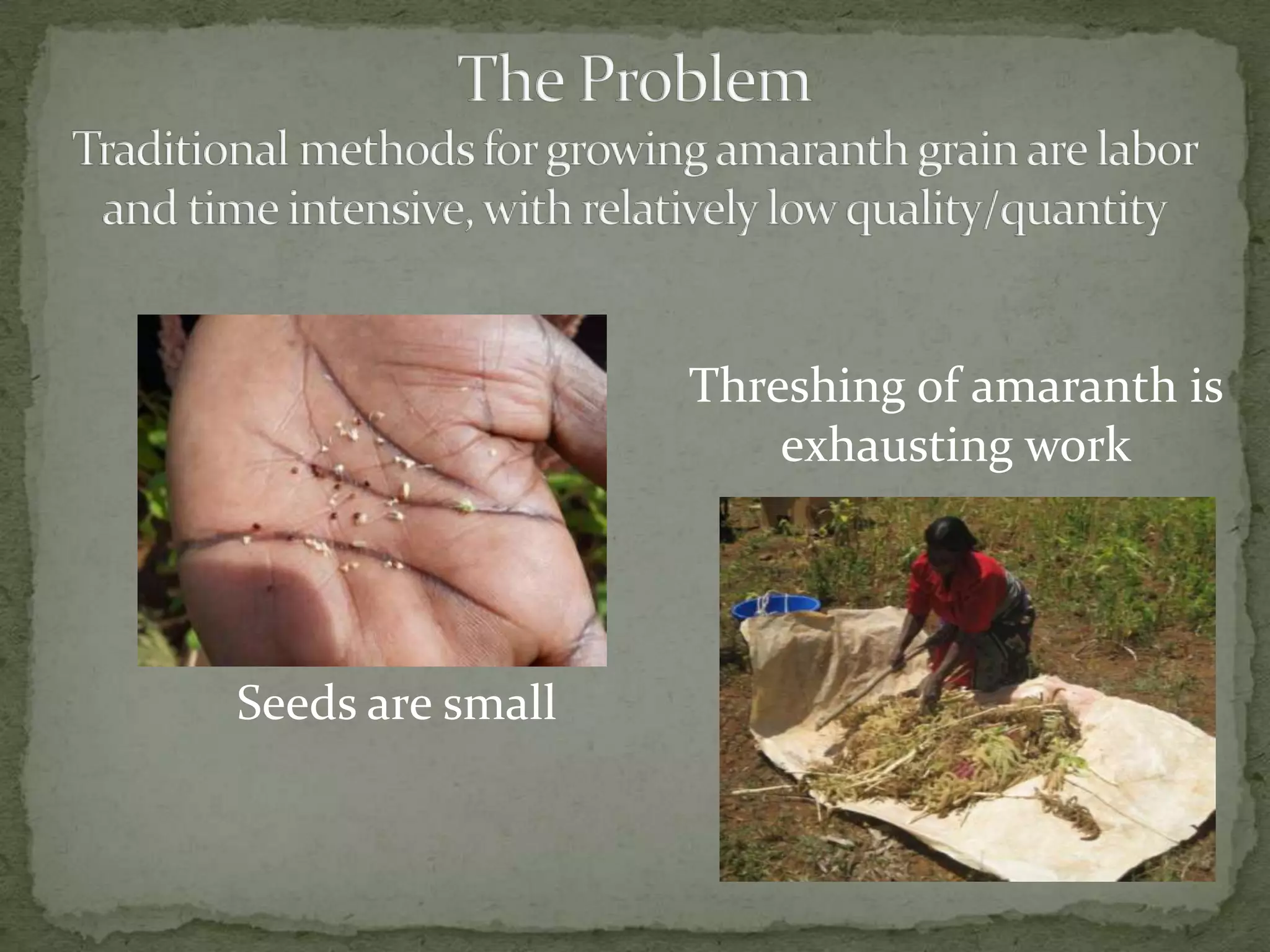

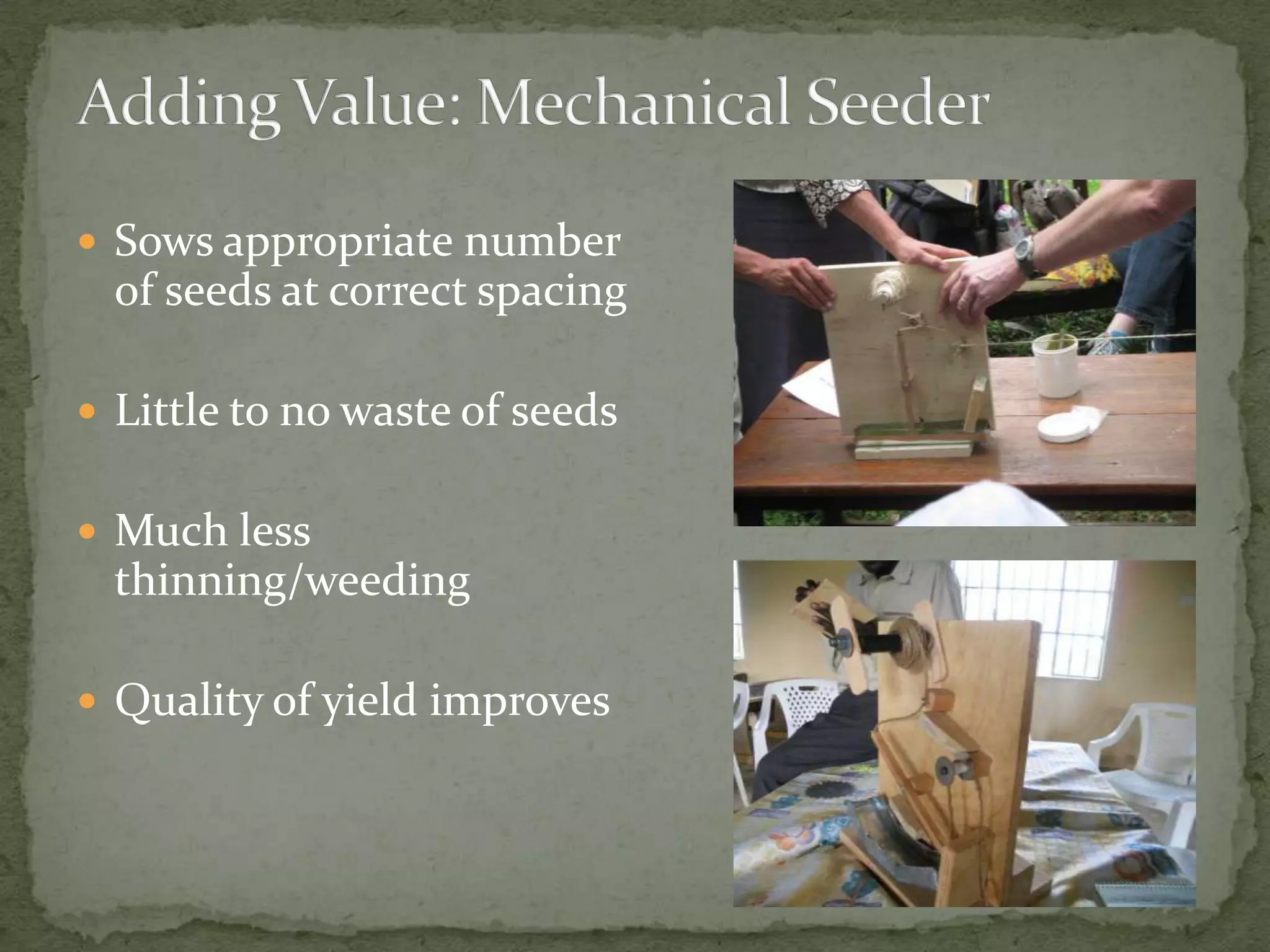

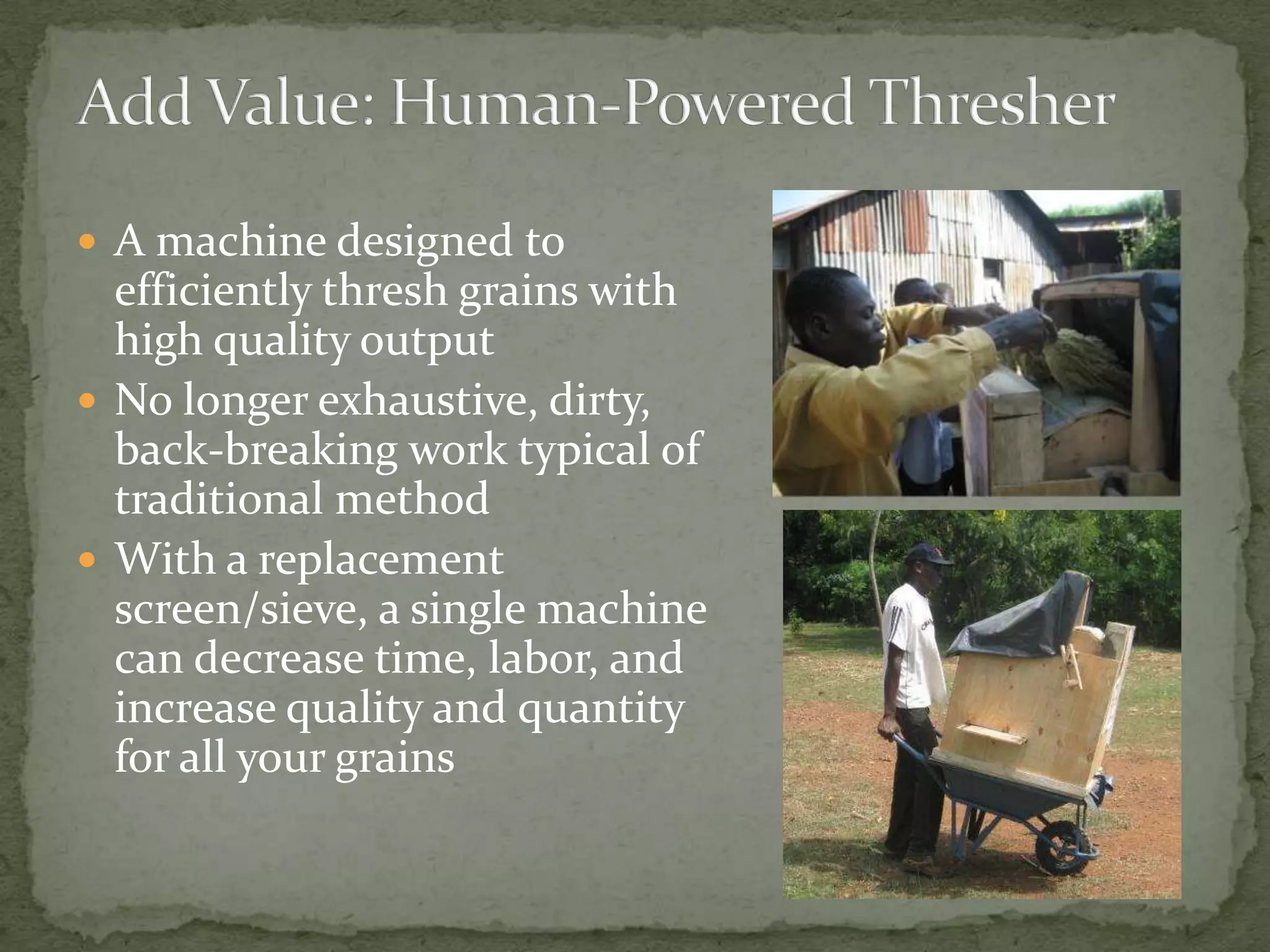

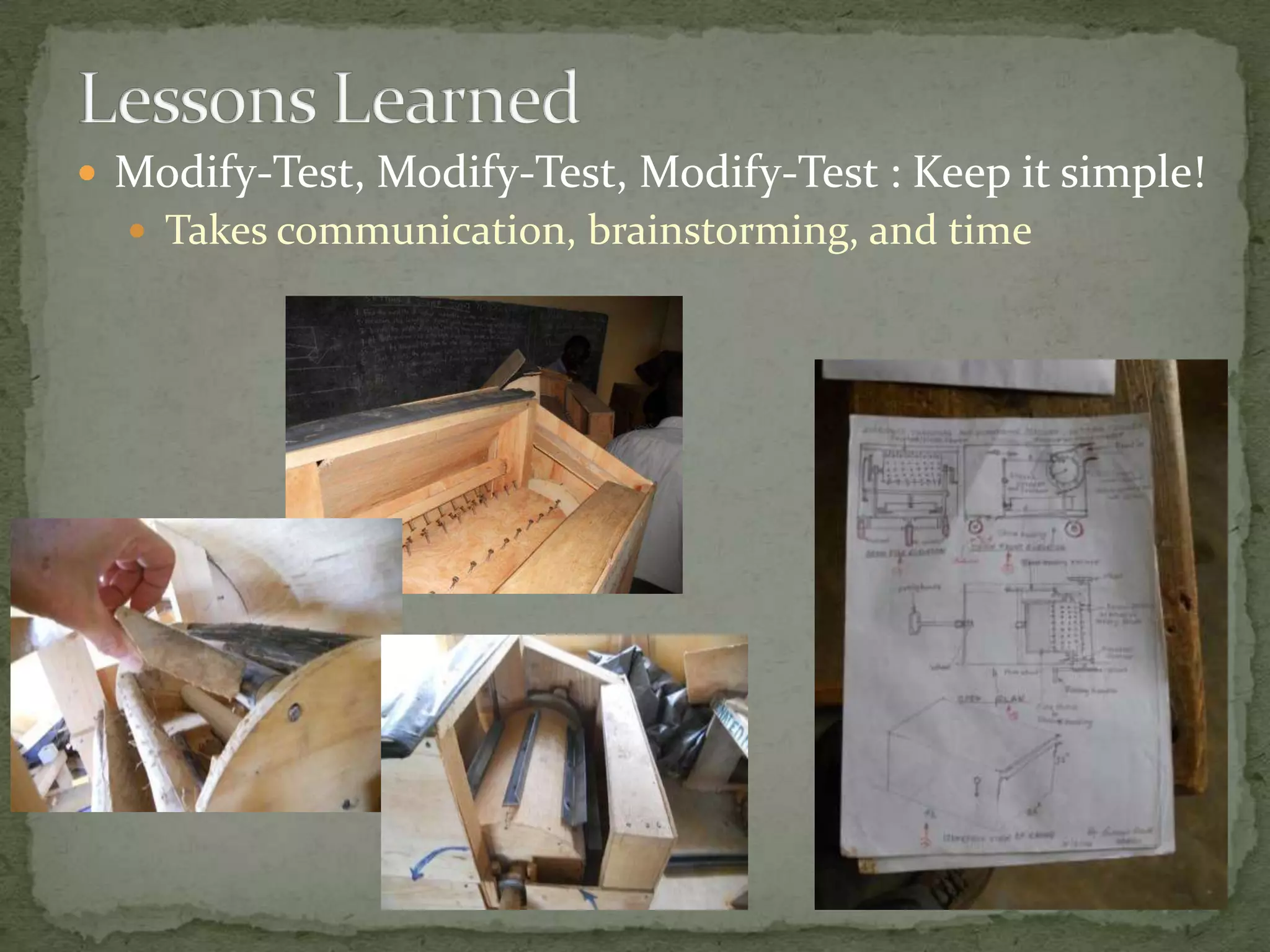

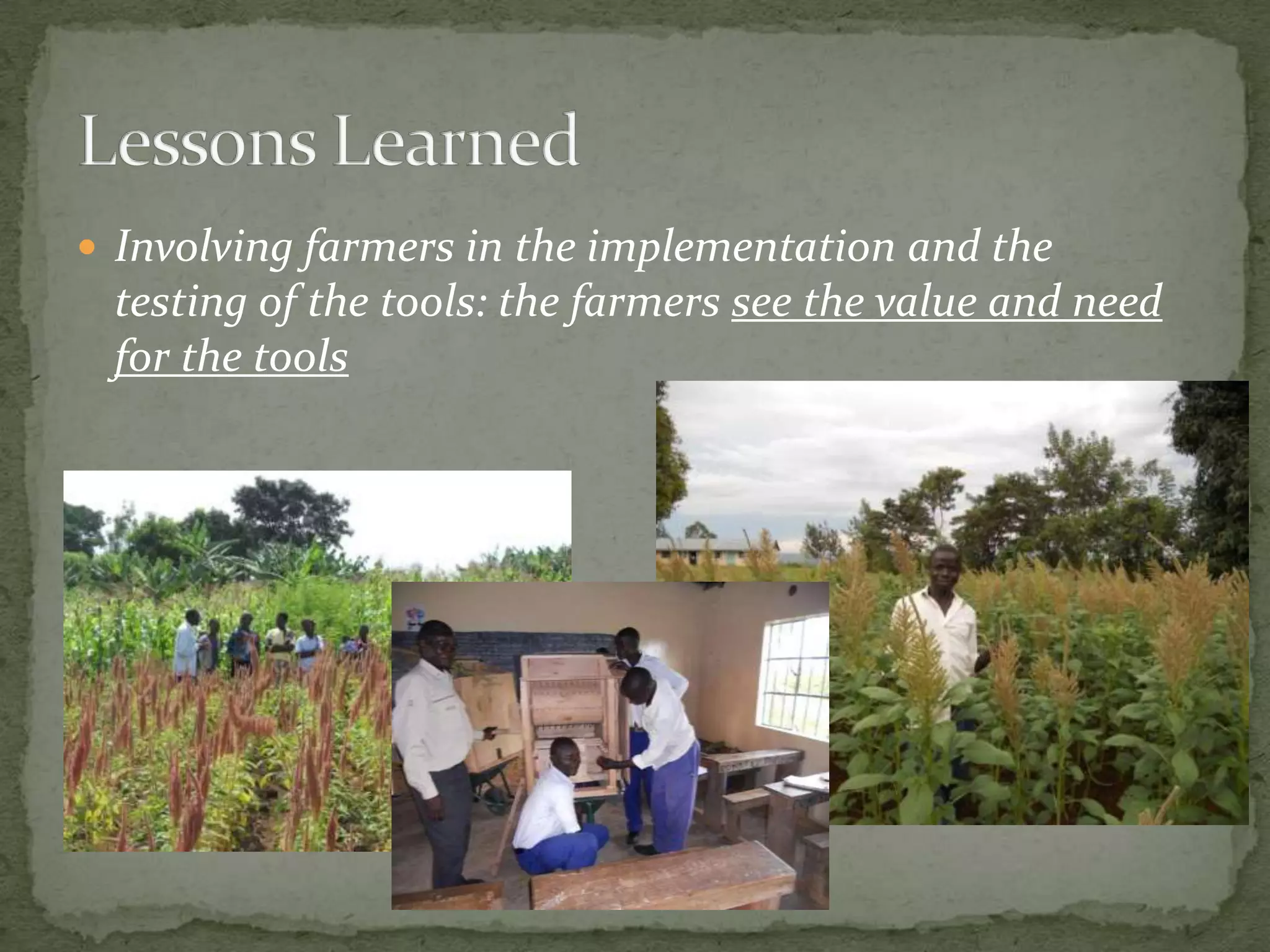

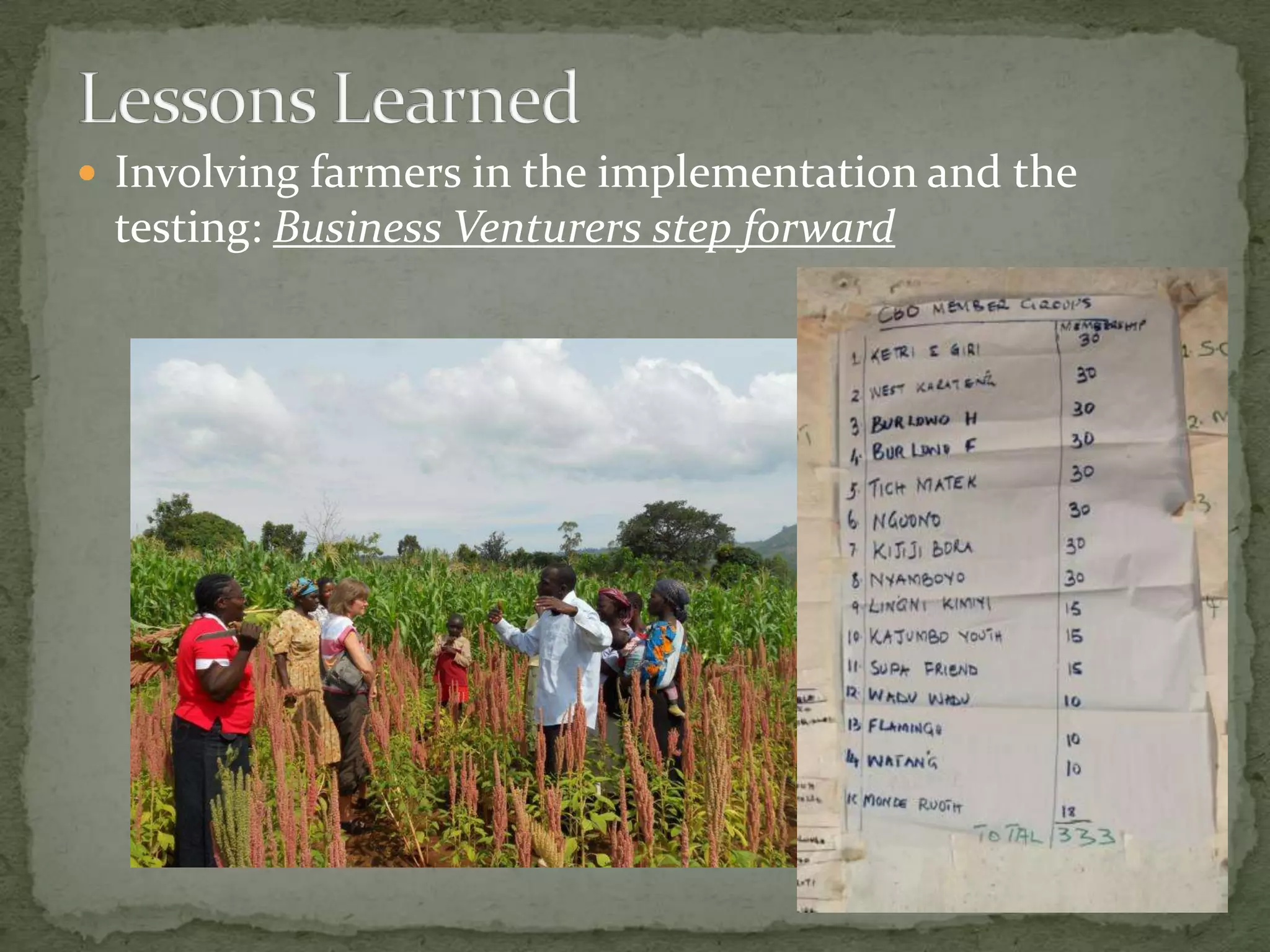

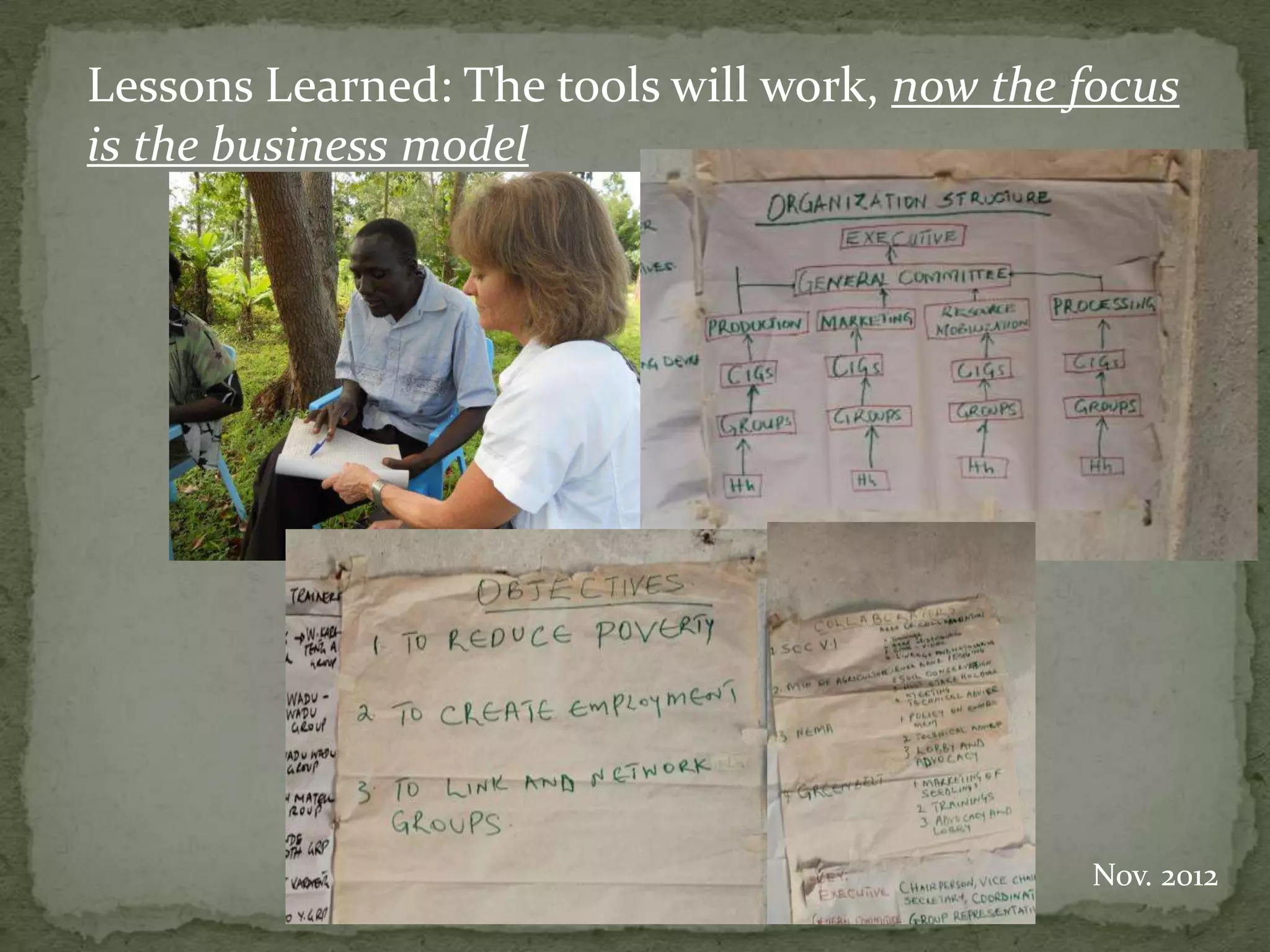

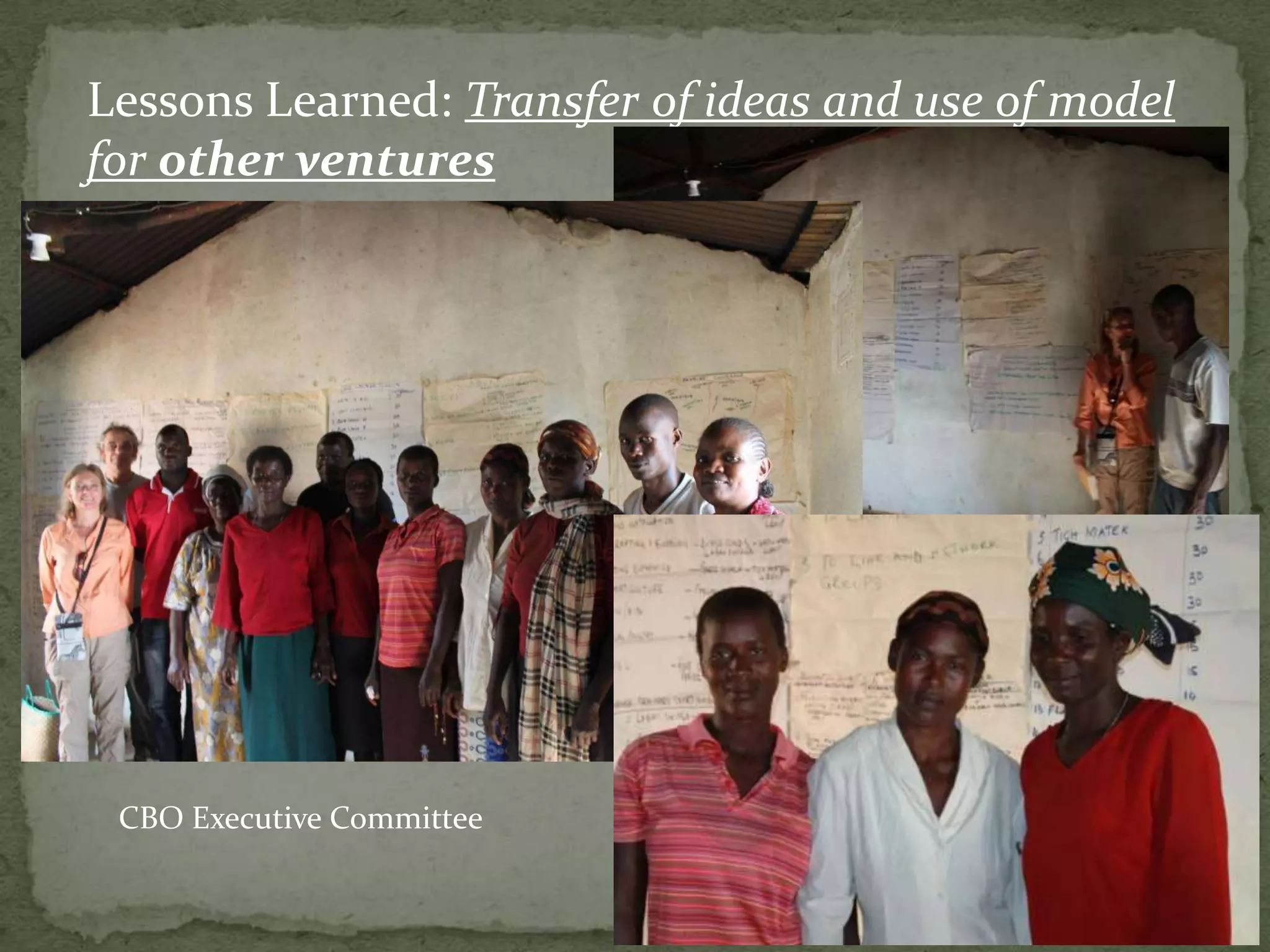

This document summarizes the development of a project to introduce mechanical tools to farmers in Western Kenya to assist in the production of the drought-resistant crop amaranth. It describes the stakeholders involved, including universities and local organizations. Prototypes were developed for a mechanical seed planter and human-powered thresher and tested on farms through a shared-use model. The testing focused on improving efficiency and quality of production. The project aims to establish local manufacturing and a business venture model to scale up the tools and amaranth production in the region.