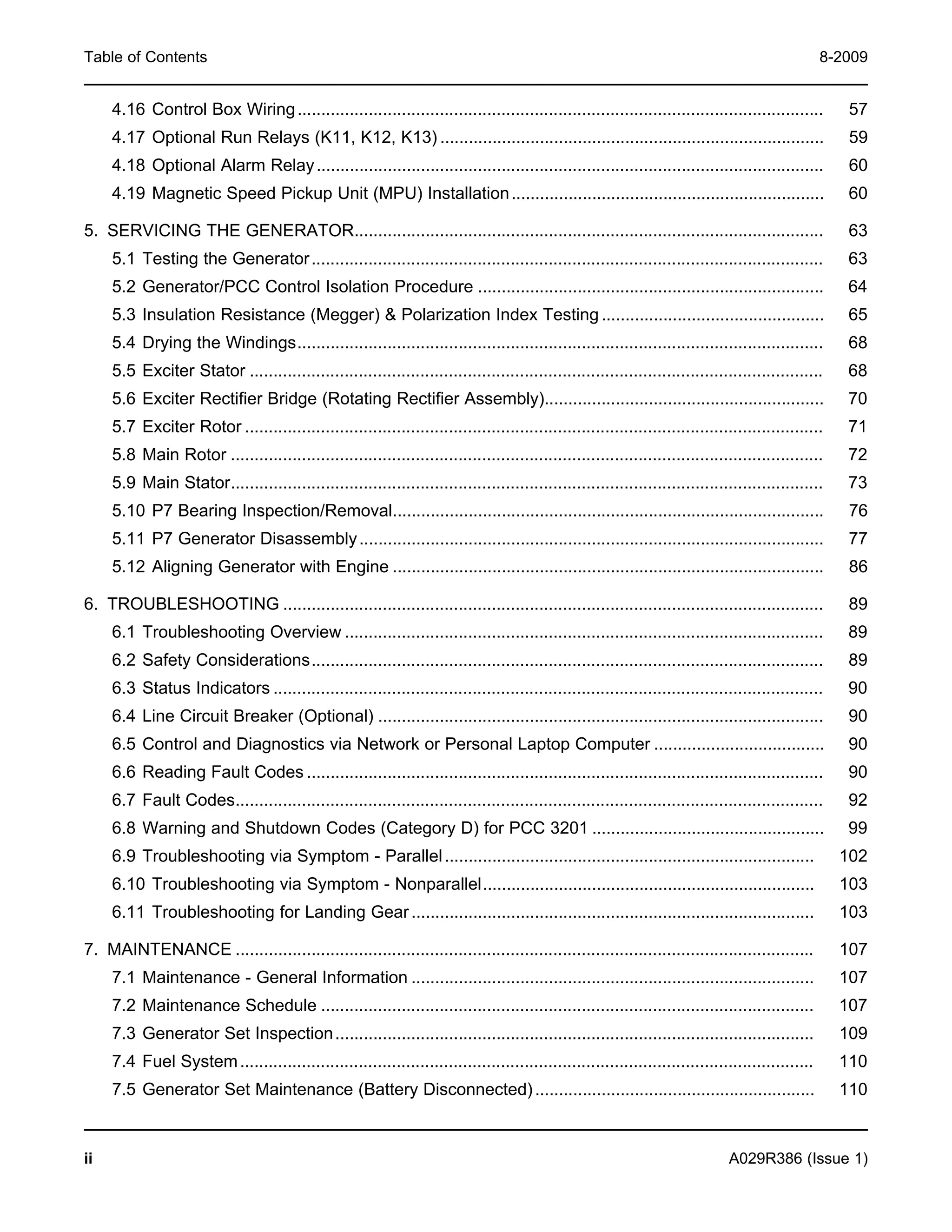

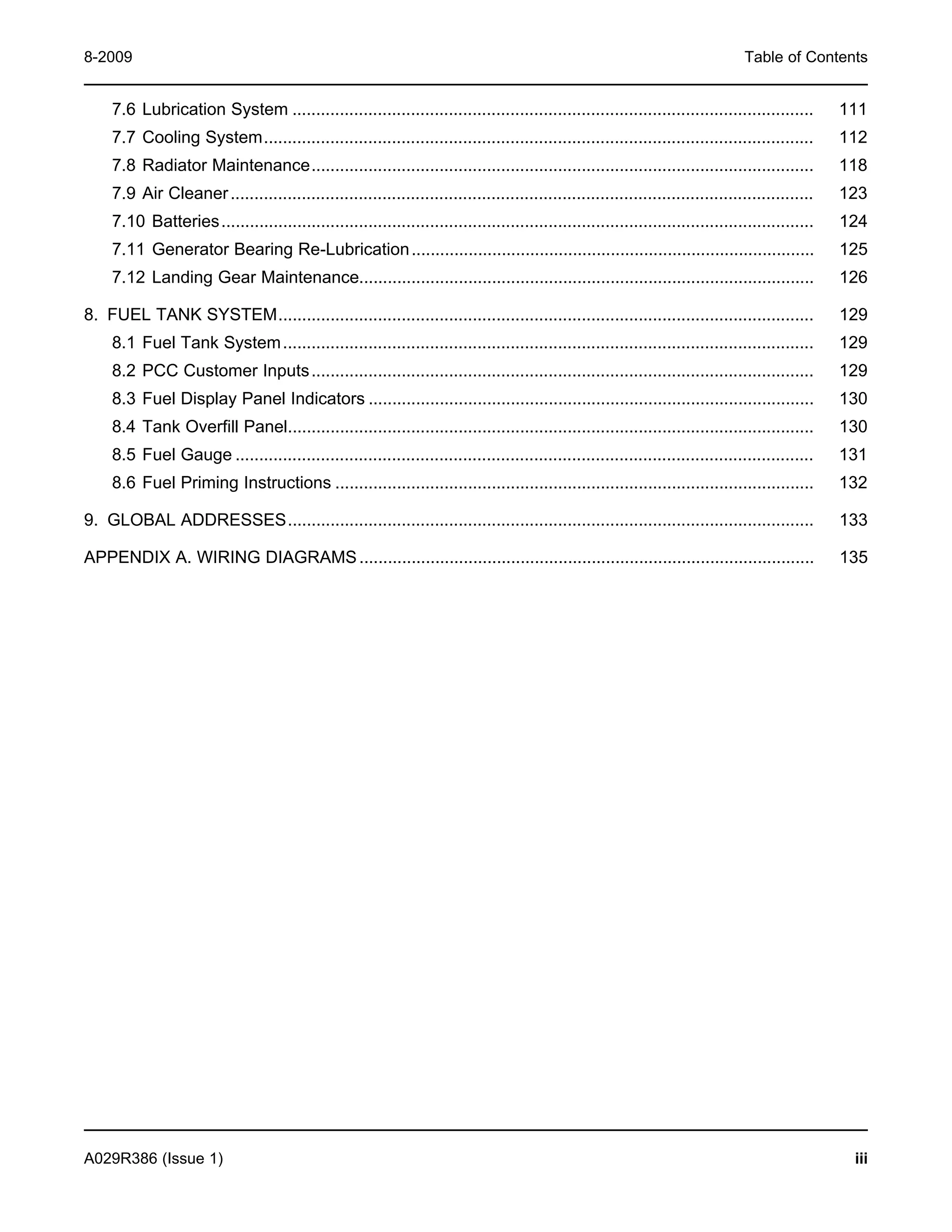

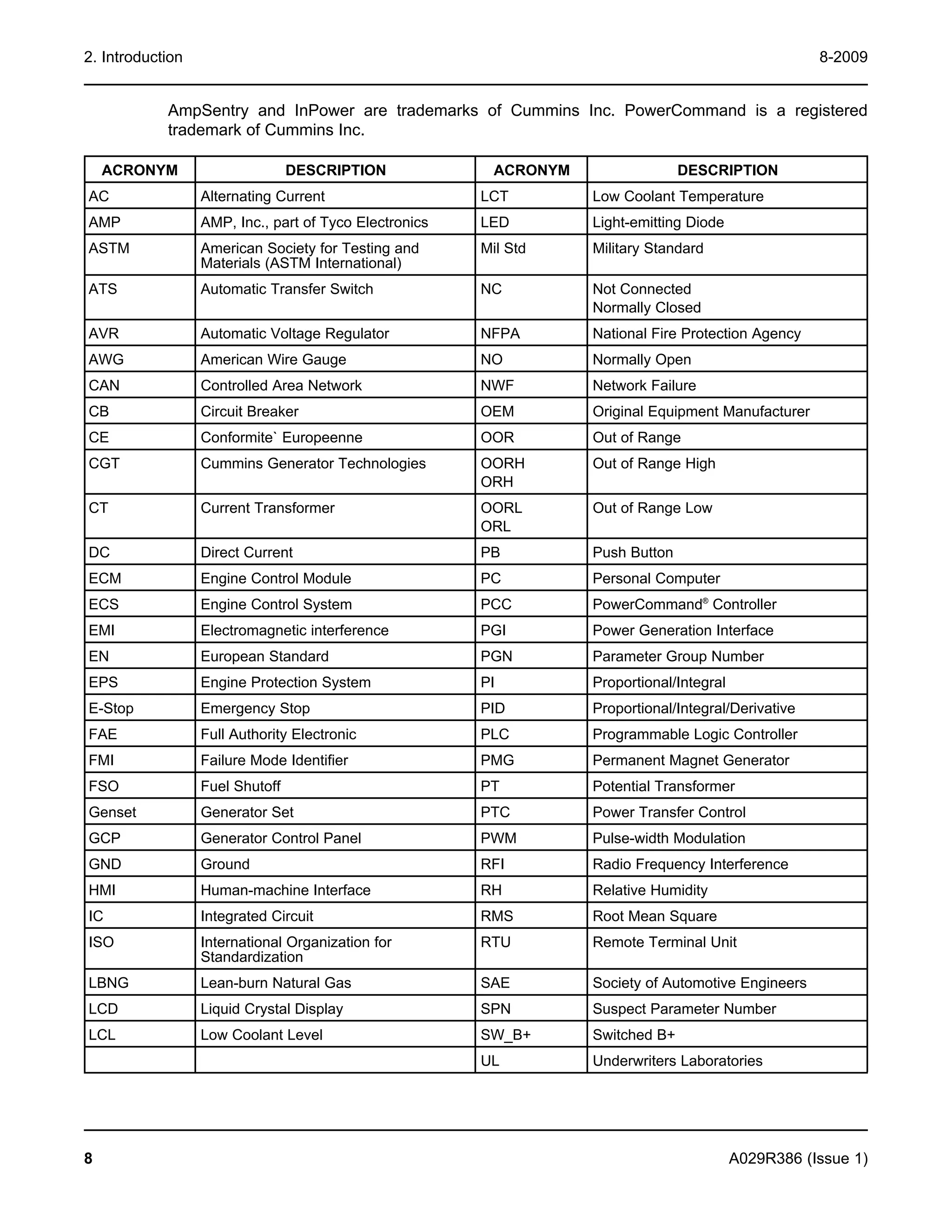

This document is a service manual for a rental package generator set with a PowerCommand 3201 controller. It contains sections on safety instructions, an introduction, the control system, control calibration and adjustment, servicing the generator, troubleshooting, and maintenance. The table of contents lists subsections on testing the generator, insulation resistance testing, drying the windings, servicing various generator components, fault codes, troubleshooting symptoms, and maintenance schedules and procedures.