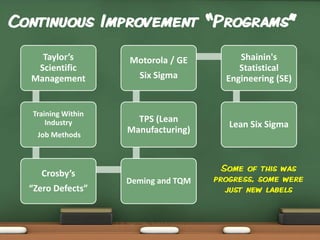

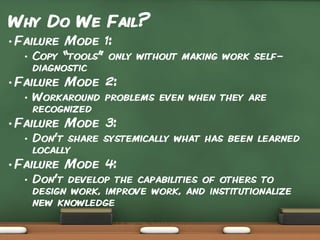

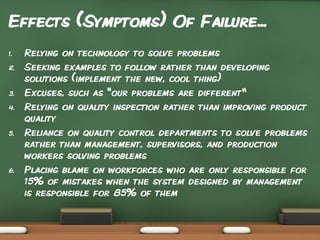

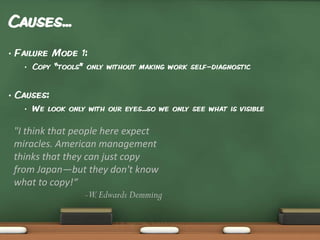

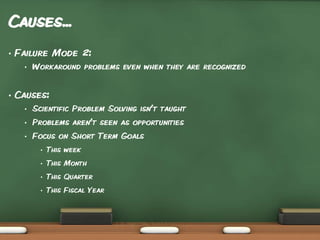

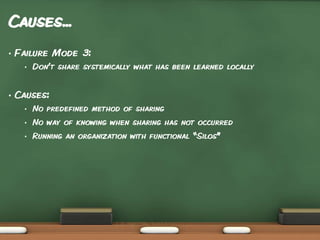

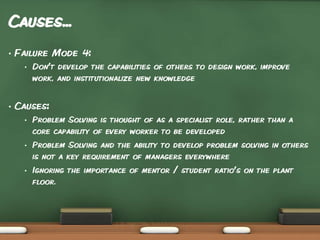

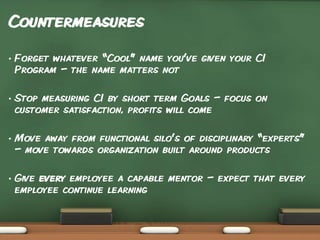

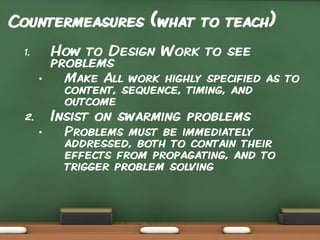

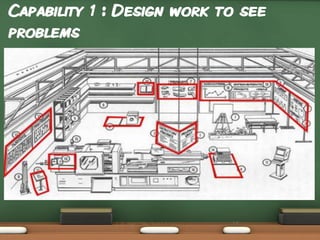

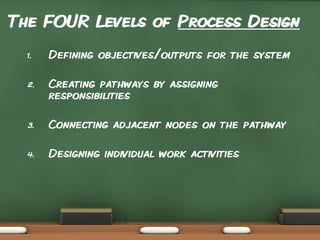

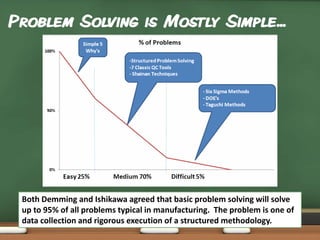

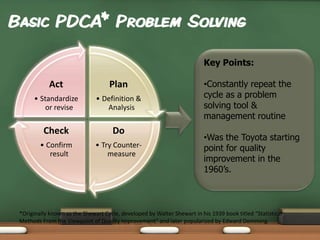

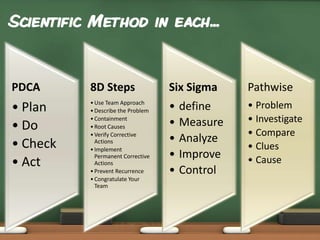

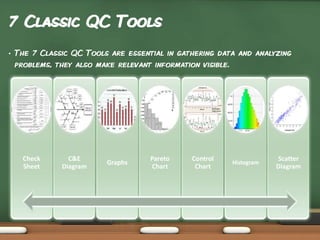

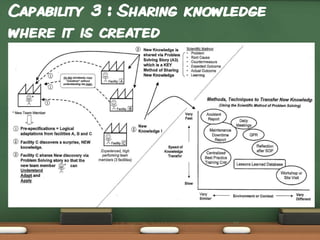

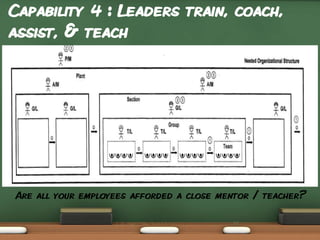

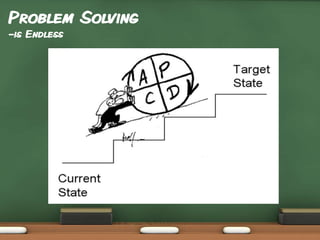

This document discusses continuous improvement programs and why they often fail. It provides an overview of common continuous improvement approaches and their failure modes. The four most common failure modes are: 1) copying tools without making work self-diagnostic, 2) working around problems rather than solving them, 3) not sharing learning across the organization, and 4) not developing problem-solving capabilities in others. The document then discusses effects of these failures, causes of the failures, and countermeasures to address the causes, including teaching scientific problem-solving methods, sharing knowledge locally, and leaders developing problem-solving skills in employees.