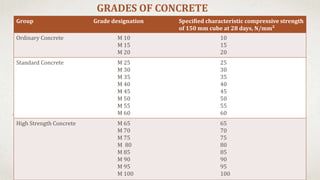

This document discusses concrete mix design. It defines mix design as determining the relative proportions of concrete ingredients to achieve desired properties economically. The key materials used are cement, fine and coarse aggregates, water, and admixtures. Mix designs can be nominal, standard, or designed. Factors that define mix proportions include compressive strength, workability, durability, aggregate type and size, water-cement ratio, and quality control. Common mix design methods are the IS, ACI, Road Note 4, and IRC 44 methods.