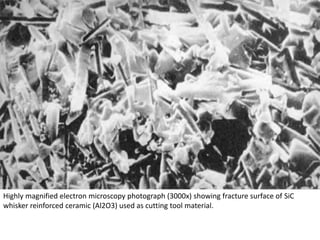

This document provides an overview of composite materials. Composites are materials composed of two or more physically distinct phases whose combination produces properties that are different from the constituent materials. The document discusses the different types of composites including metal matrix composites, ceramic matrix composites, and polymer matrix composites. It describes the components that make up each type of composite including the matrix and reinforcing materials. Various applications of composites are also mentioned.