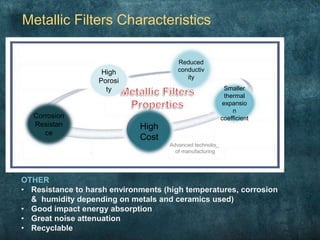

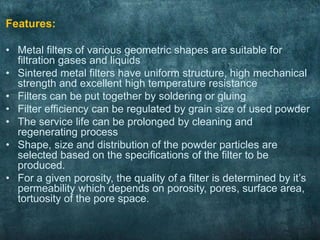

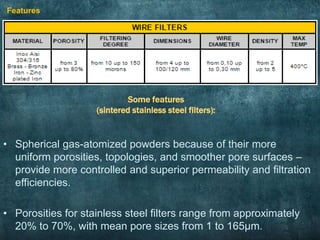

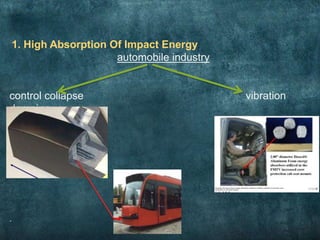

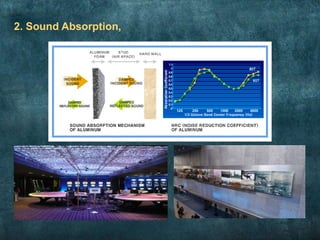

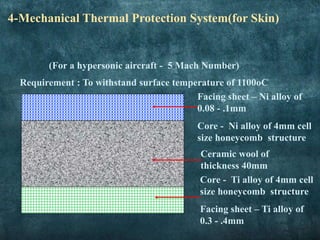

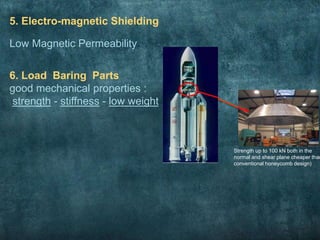

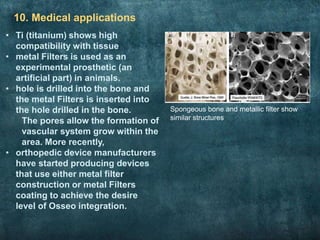

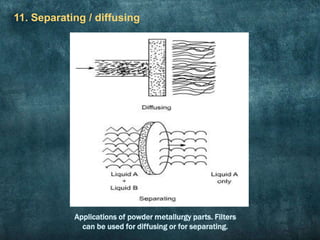

Metallic filters can be manufactured through powder metallurgy techniques like cold isostatic pressing and sintering metal powders. Common materials used include stainless steel, titanium, and aluminum alloys. Metallic filters have applications in filtration, heat exchange, sound absorption, energy absorption, and medical implants due to their uniform porosity, mechanical strength, and corrosion resistance. Key advantages over solid metals include lower density, higher surface area, and ability to form complex 3D shapes.