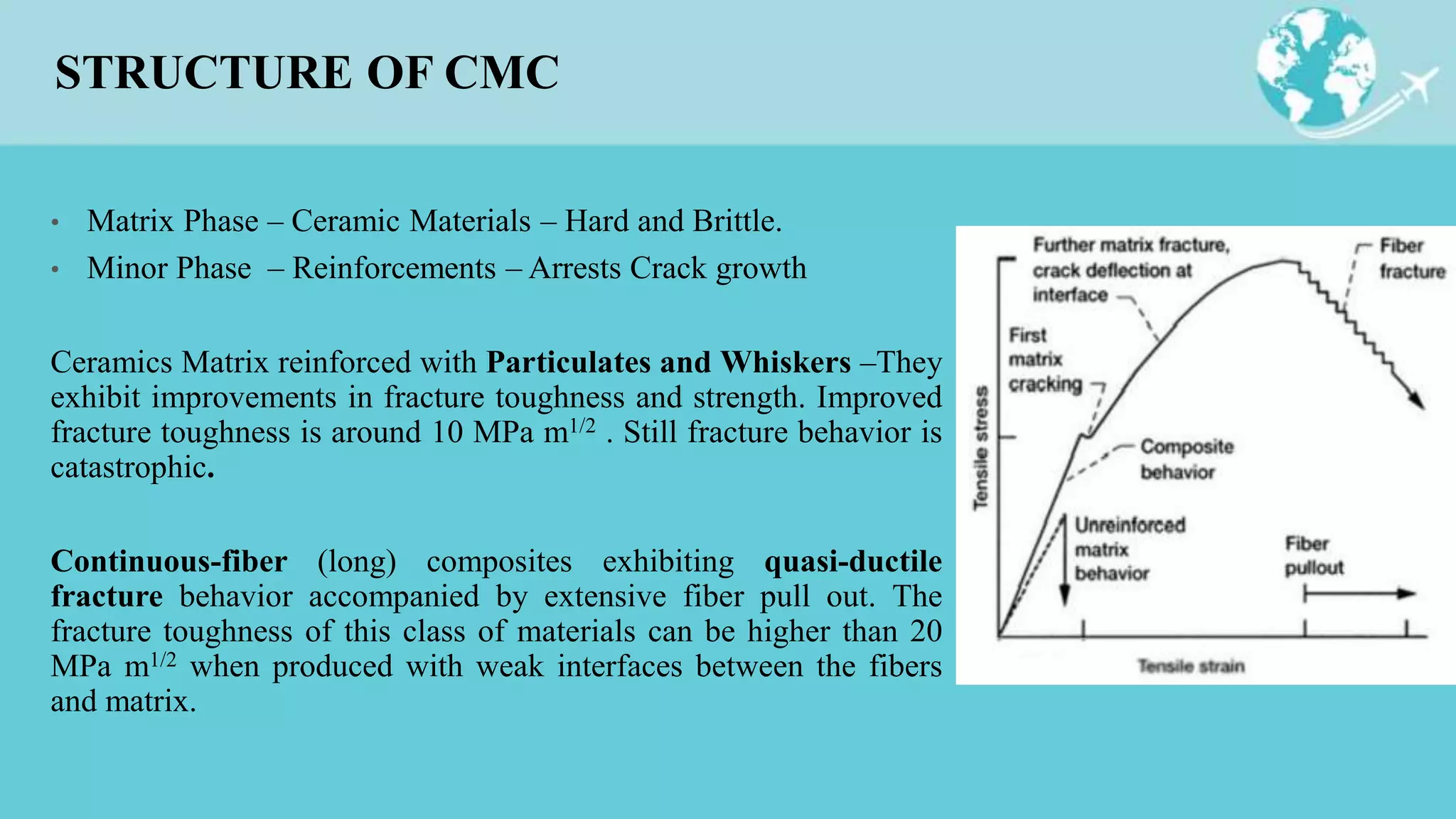

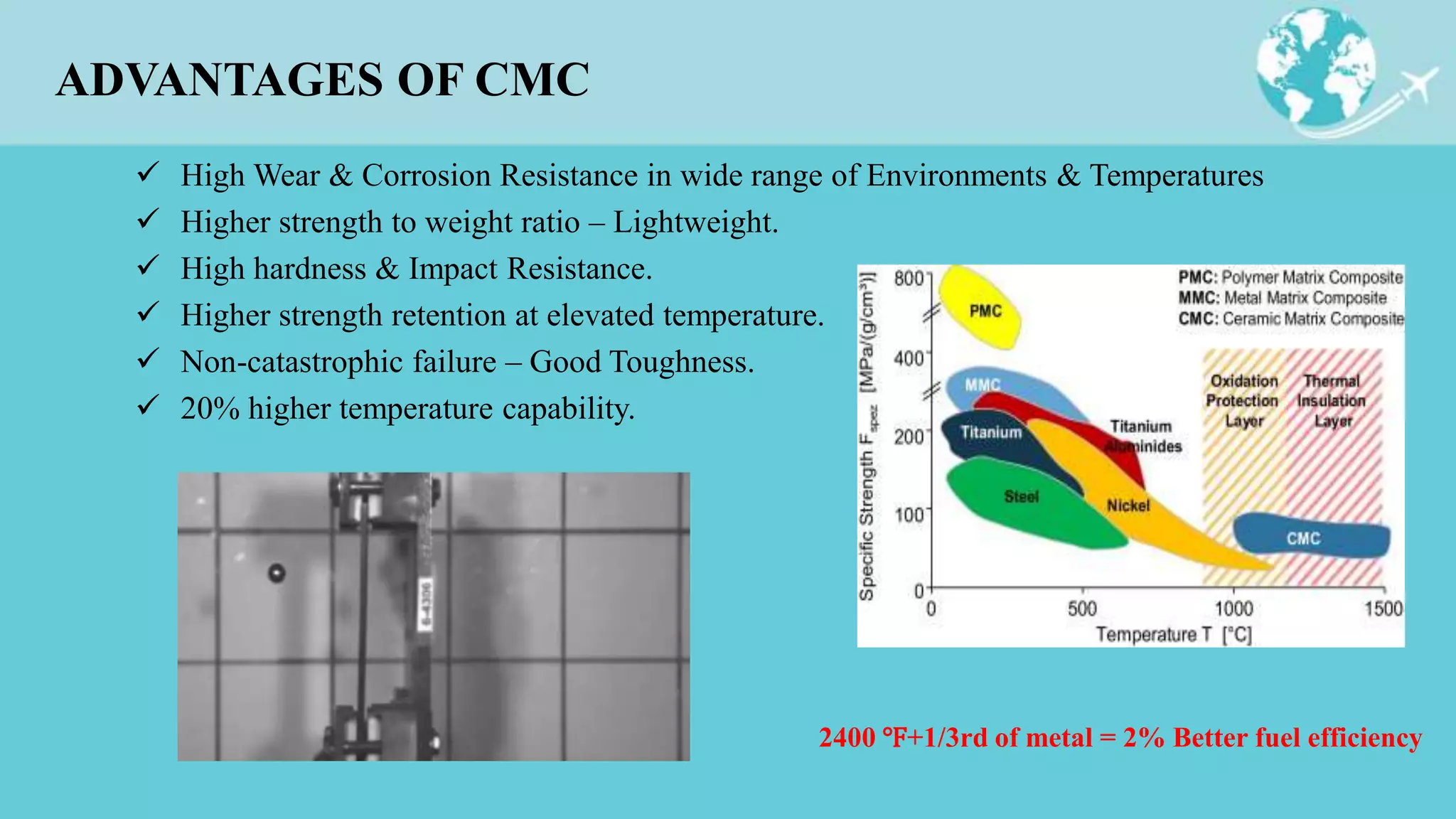

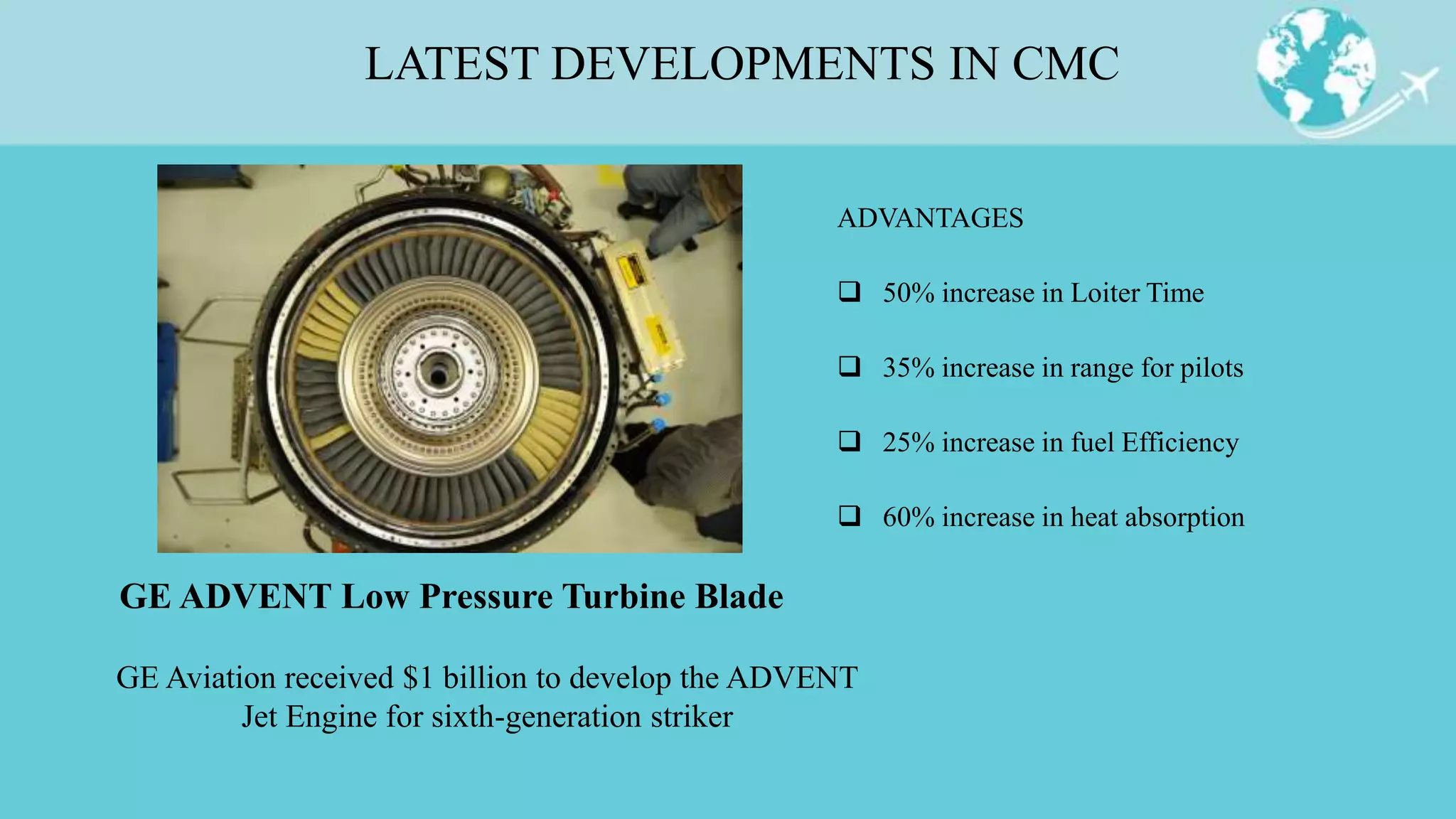

The document discusses the application of ceramic composite materials (CCM) in aviation, highlighting their advantages over conventional materials like superalloys, including improved strength-to-weight ratio, wear and corrosion resistance, and enhanced toughness. It outlines the structure, properties, challenges, and applications of CCMs, particularly in high-temperature environments and advanced aerospace technologies. Recent developments, such as GE's adaptive versatile engine technology, demonstrate the benefits of CCMs in enhancing fuel efficiency and performance in jet engines.

![[1] Ceramic Matrix Composites: Processing Techniques and Recent advancements by Neera Singh et.al

Journal of Materials and Environmental Sciences – 2017 Volume 8 Issue 5 ISSN : 2028-2508

[2] Ceramic Matrix Composites Manufacturing and Applications in the Automotive Industry by Diego Brach

García, Advanced Composite Centre for Innovation and Science - University of Bristol

[3] Ceramic Matrix Composites (CMC) for demanding Aerospace and Terrestrial Applications Dr. Karin E.

Handrick – MT Aerospace XXI C AIV – Catania May 2013

[4] Modelling of Damage and Fracture In Ceramic Matrix Composites – An Overview by Michał Basista in

Journal of Theoretical and Applied Mechanics 2006 Volume 44, Page 454 -484

[5] Comprehensive Composite Materials, Volume 4: Carbon/Carbon, Cement, and Ceramic Matrix Composites,

4.01 Matrix Materials, R. MORRELL

REFERENCES](https://image.slidesharecdn.com/ceramicpresentation-180316073646/75/Application-of-Ceramic-Composite-Materials-in-Aviation-15-2048.jpg)