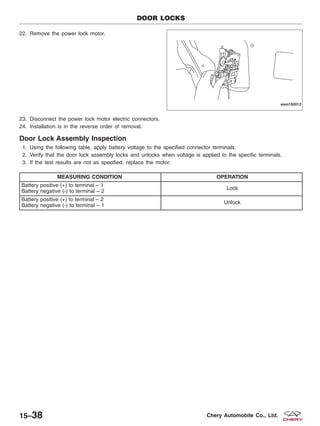

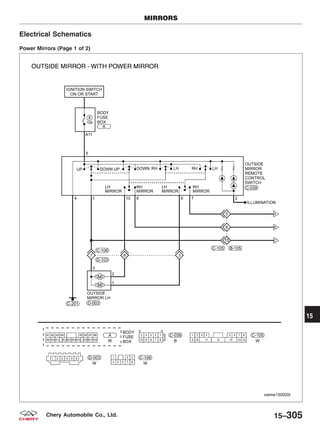

This document provides information for diagnosing electrical failures, including performing efficient diagnosis, simulating failure conditions, handling electrical components safely, and checking connectors. Key steps include obtaining details on the failure, inspecting for physical issues, using diagrams to determine involved circuits, repairing or replacing components, and verifying the system works properly under all conditions. Failure simulations include tests for vehicle vibration, heat, freezing, water intrusion, electrical load changes, and cold/hot starts.