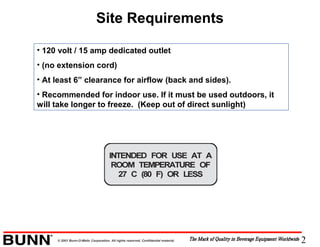

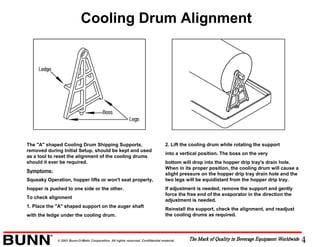

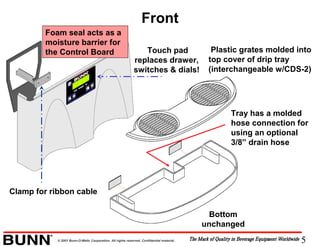

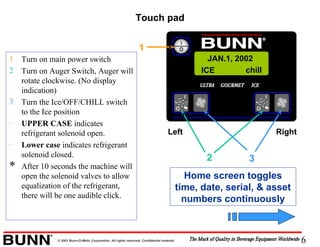

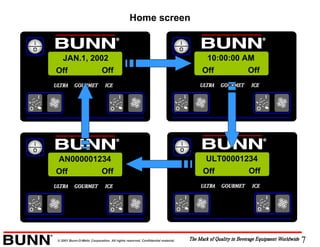

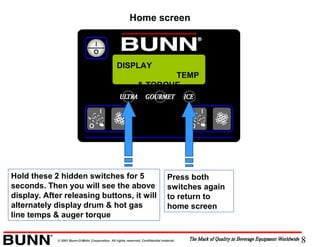

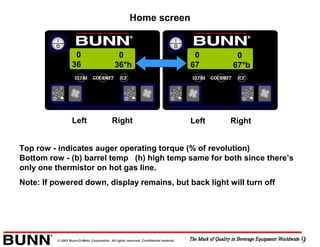

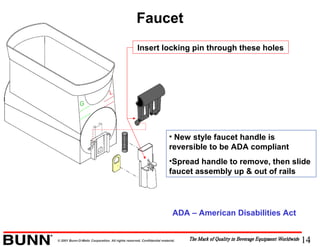

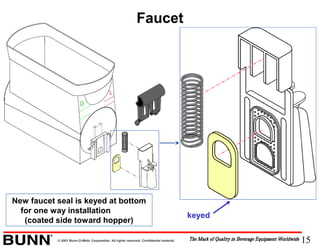

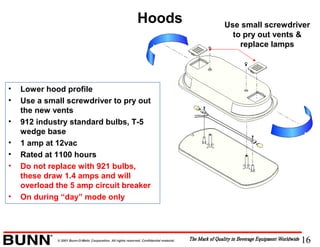

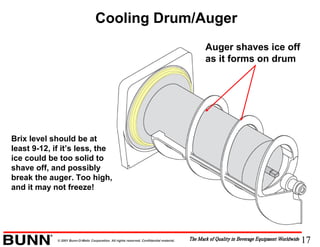

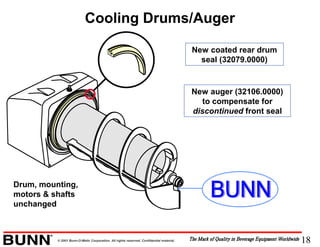

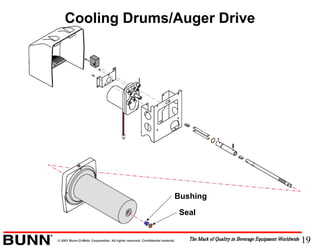

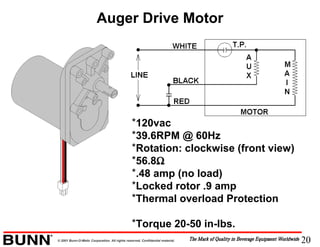

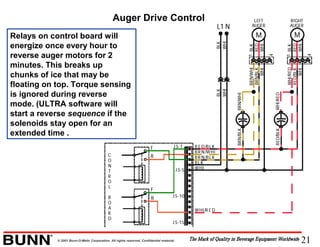

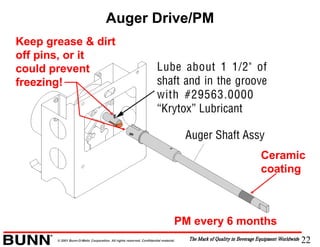

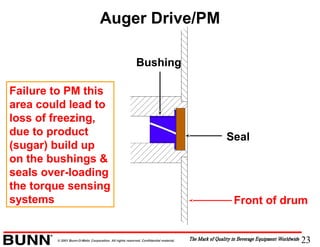

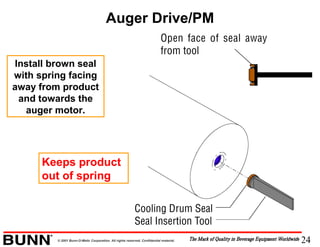

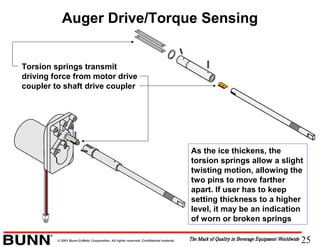

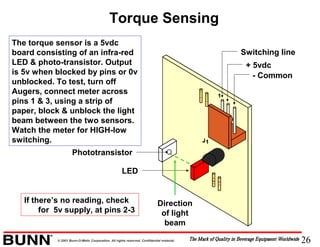

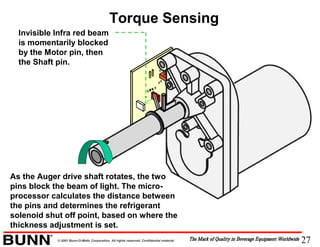

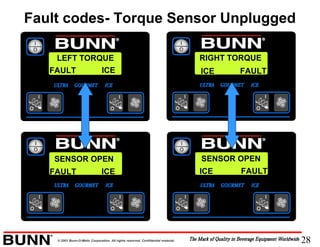

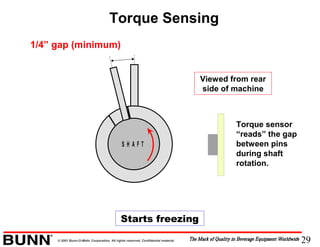

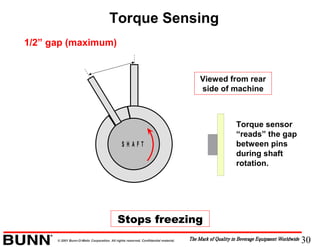

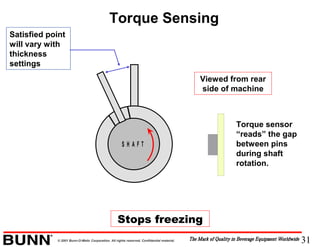

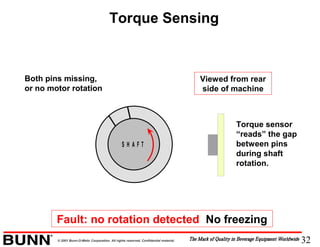

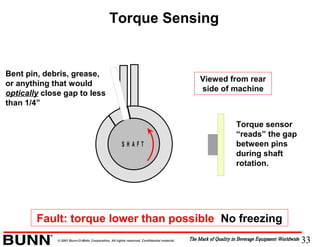

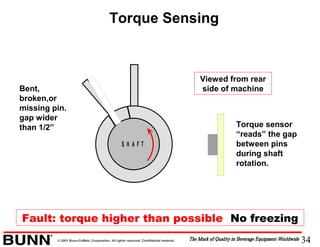

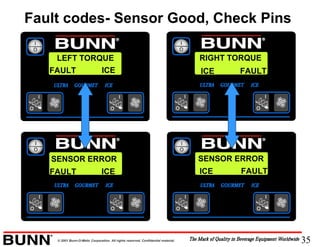

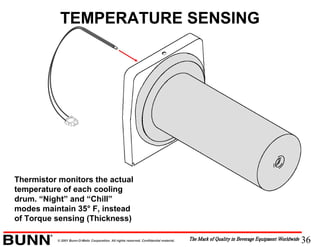

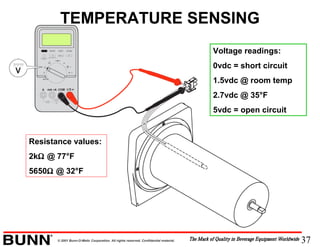

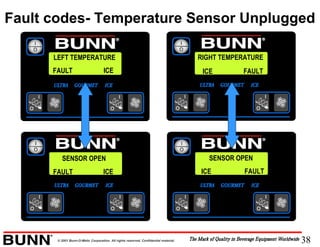

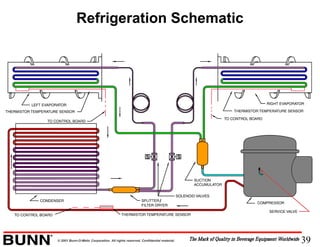

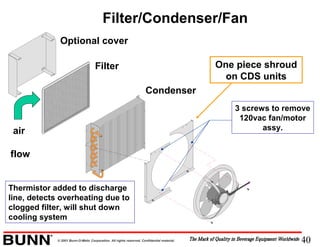

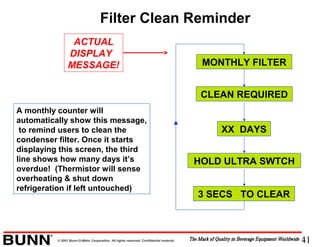

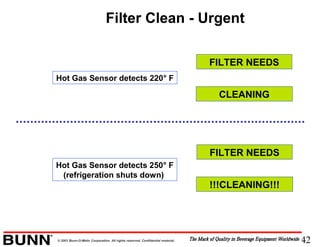

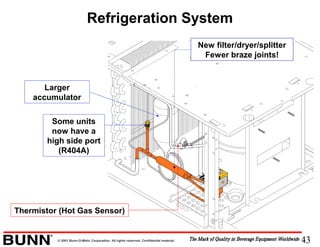

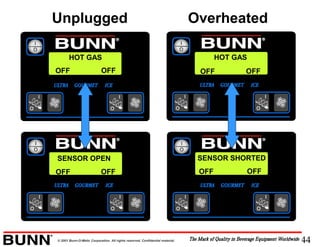

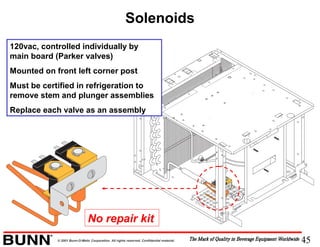

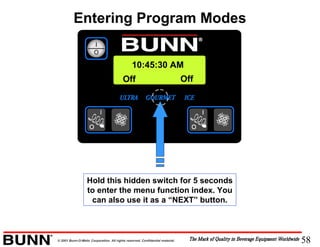

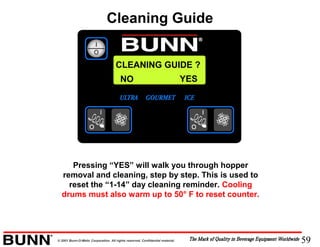

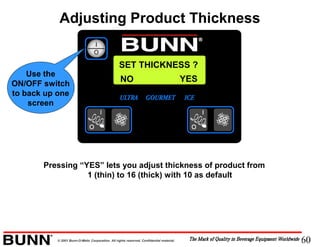

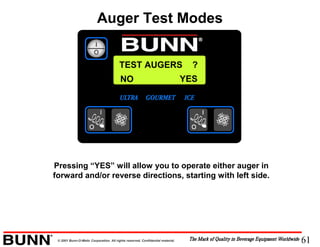

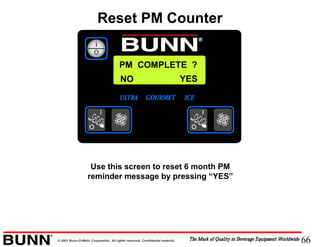

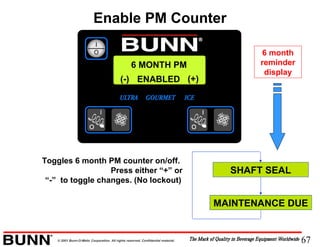

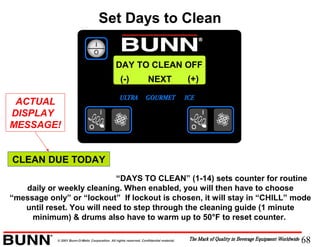

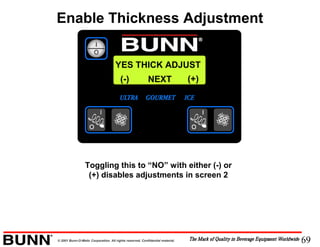

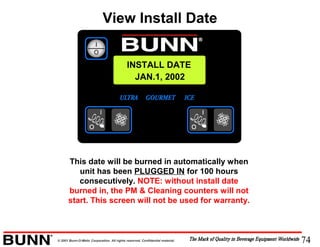

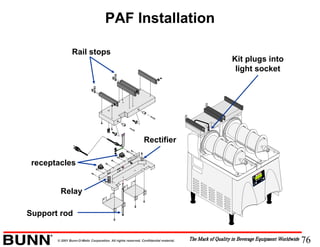

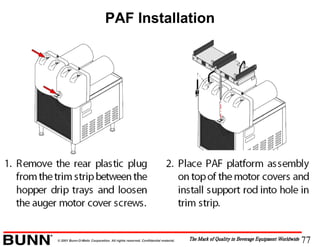

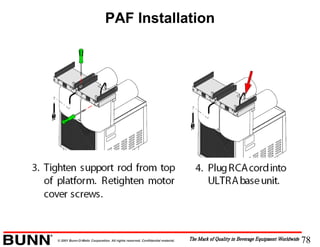

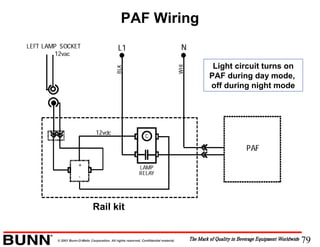

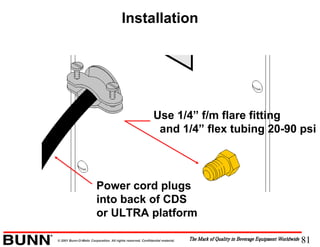

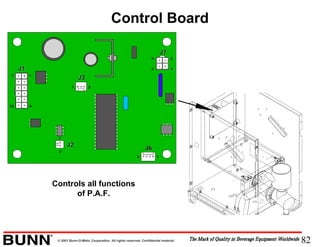

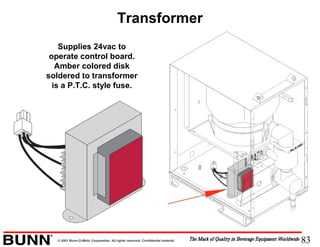

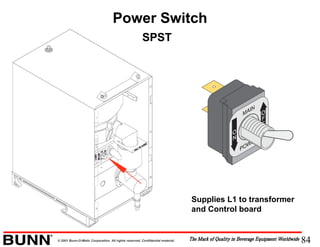

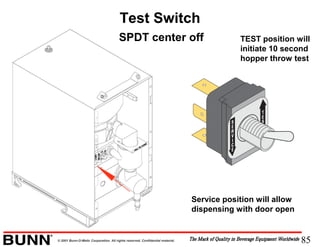

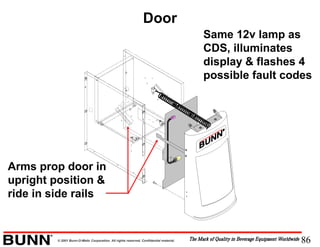

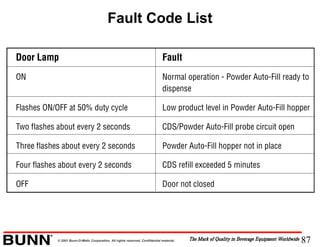

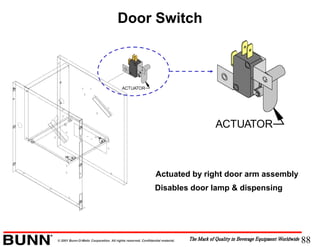

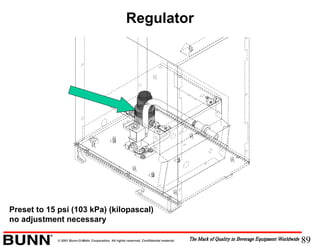

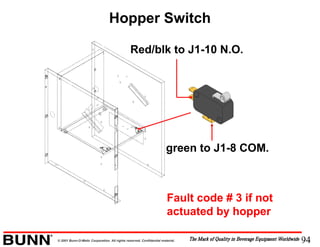

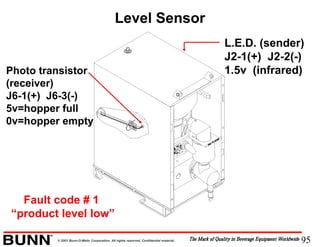

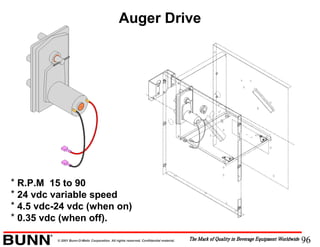

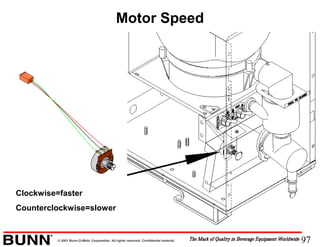

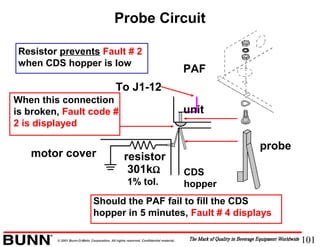

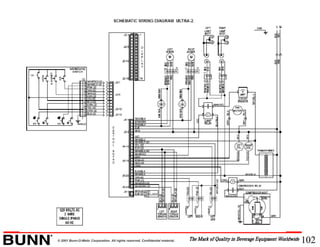

The document is a detailed instructional guide for the installation and operation of a Bunn-O-Matic machine, emphasizing site requirements, machine setup, and maintenance protocols. It includes specific information on cooling drum alignment, electrical operations, fault codes, and component details for troubleshooting. Safety and operational efficiency are highlighted, with reminders for regular maintenance tasks such as filter cleaning and temperature monitoring.