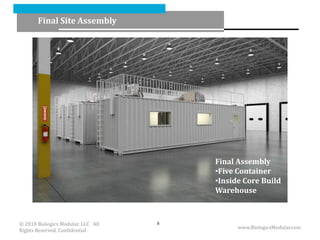

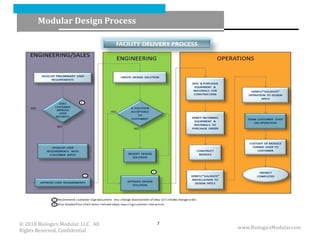

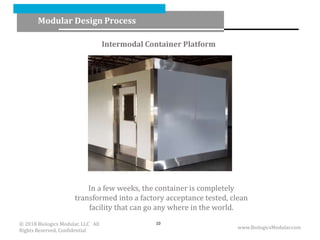

Biologics Modular designs and manufactures modular facilities for biomanufacturing. Their DeployReady Platform uses pre-engineered modular designs that allow for cost-effective and flexible manufacturing facilities. The modular designs can be transported globally and assembled on site, providing a standardized approach to setting up biomanufacturing operations anywhere in the world.