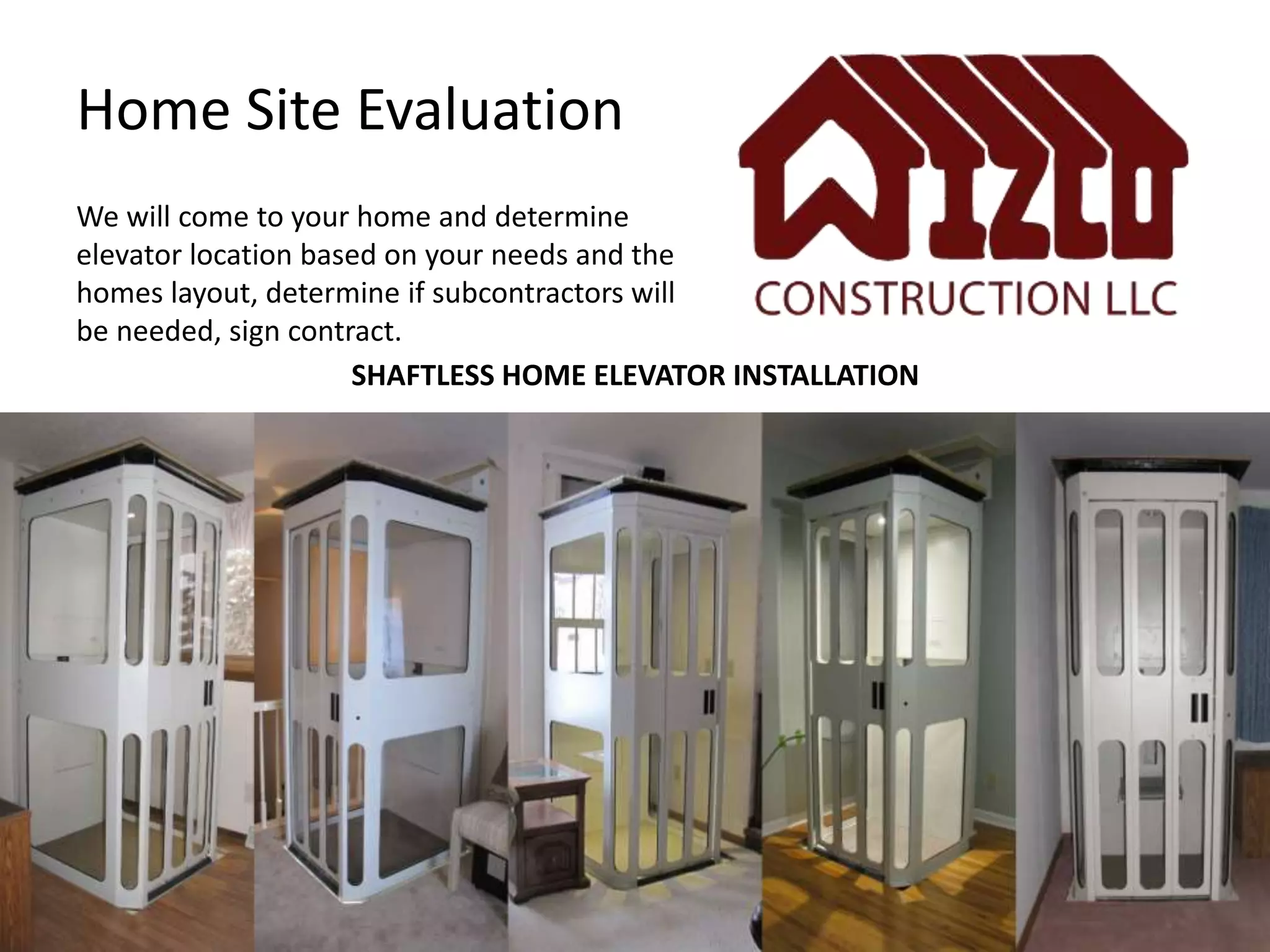

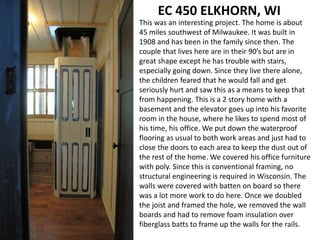

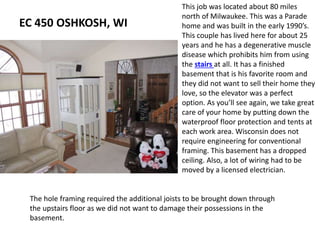

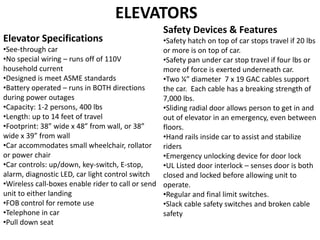

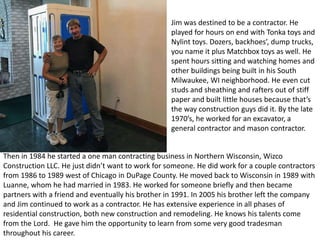

The document discusses the evaluation and installation process for shaftless home elevators in two Wisconsin homes, addressing the specific needs of elderly residents with mobility issues. It provides details on the elevators' specifications, safety features, and the installation process, emphasizing a careful approach to protect the homes. Additionally, it includes a brief background on the contractor's experience in residential construction.