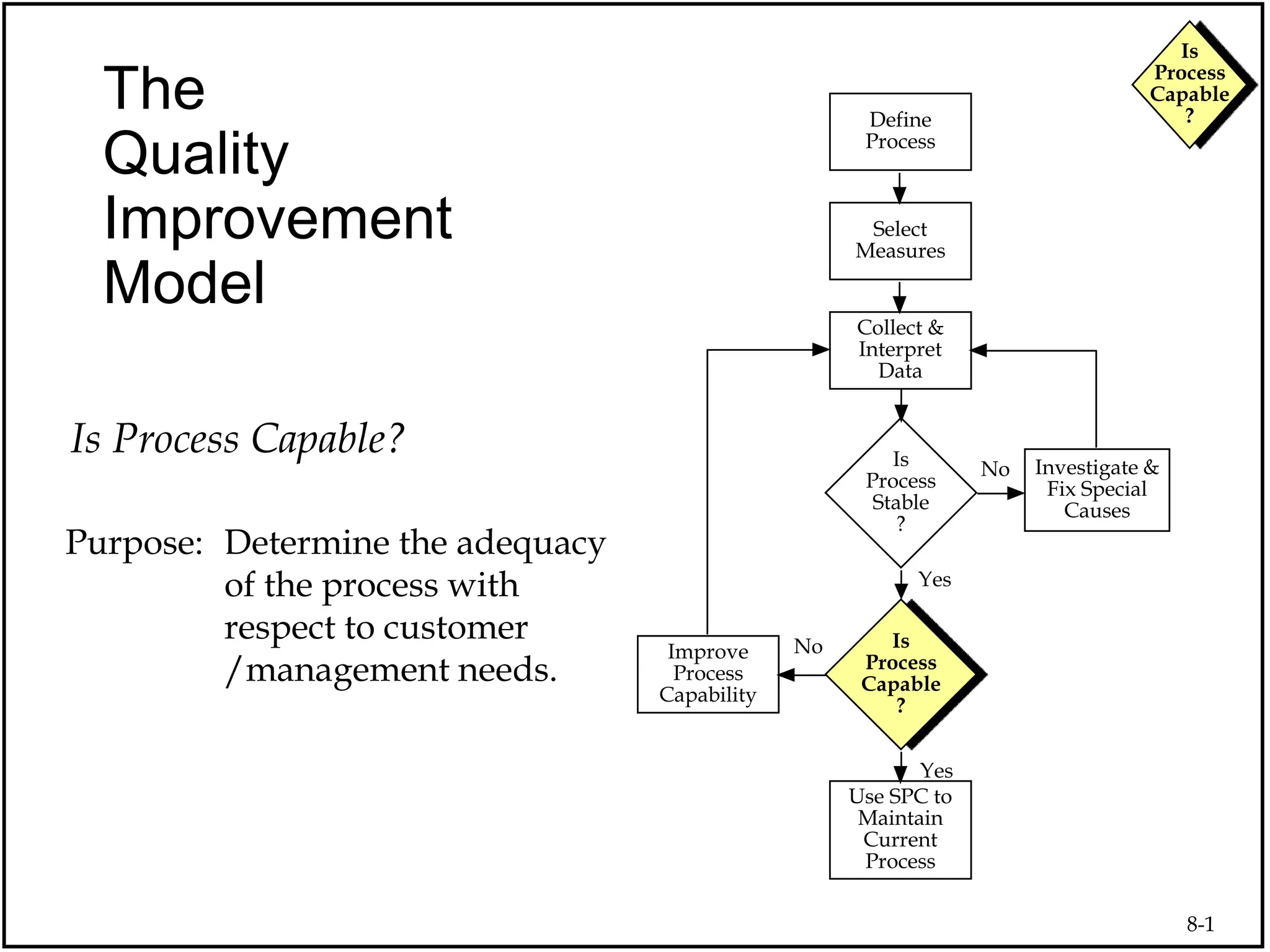

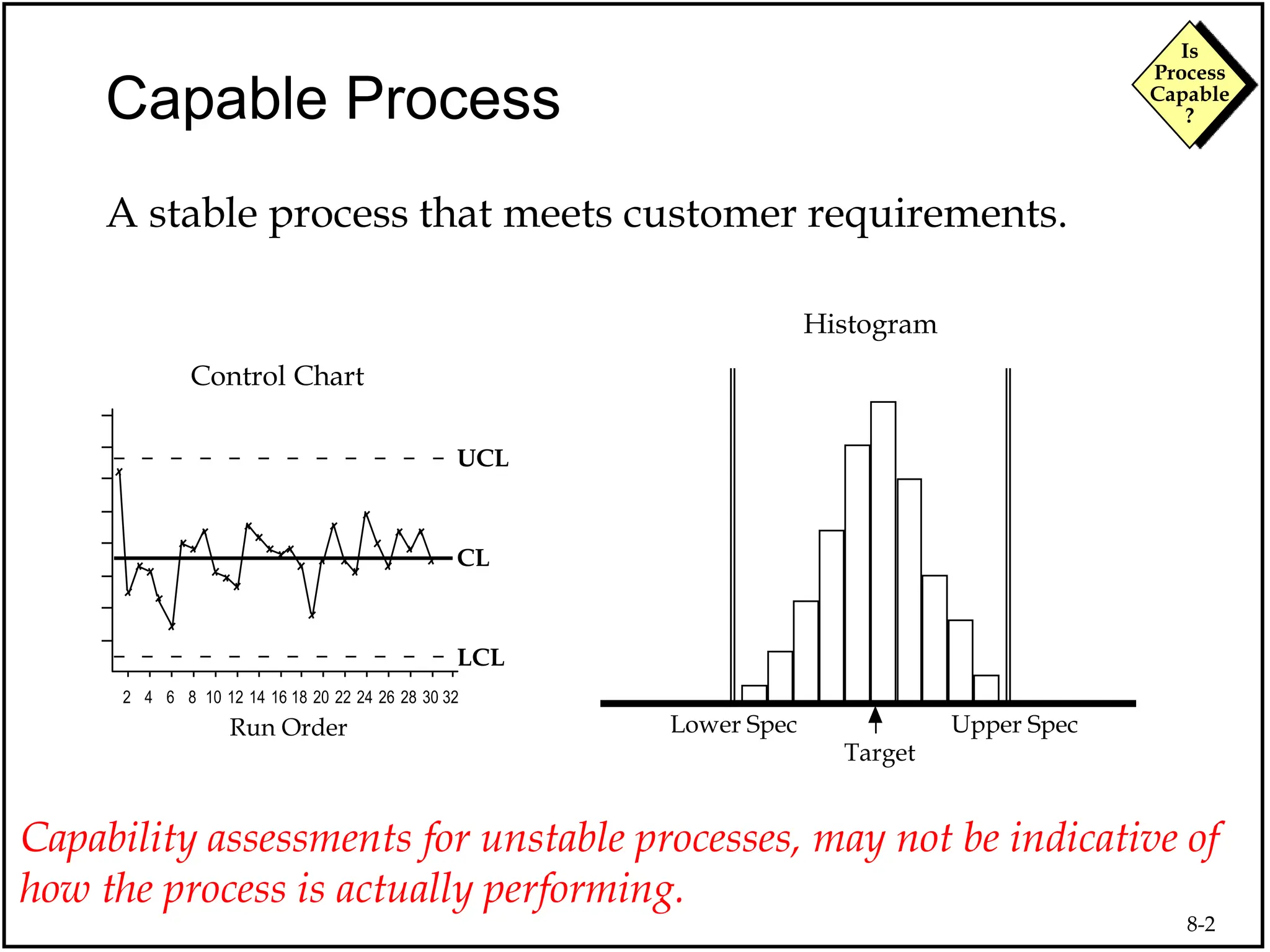

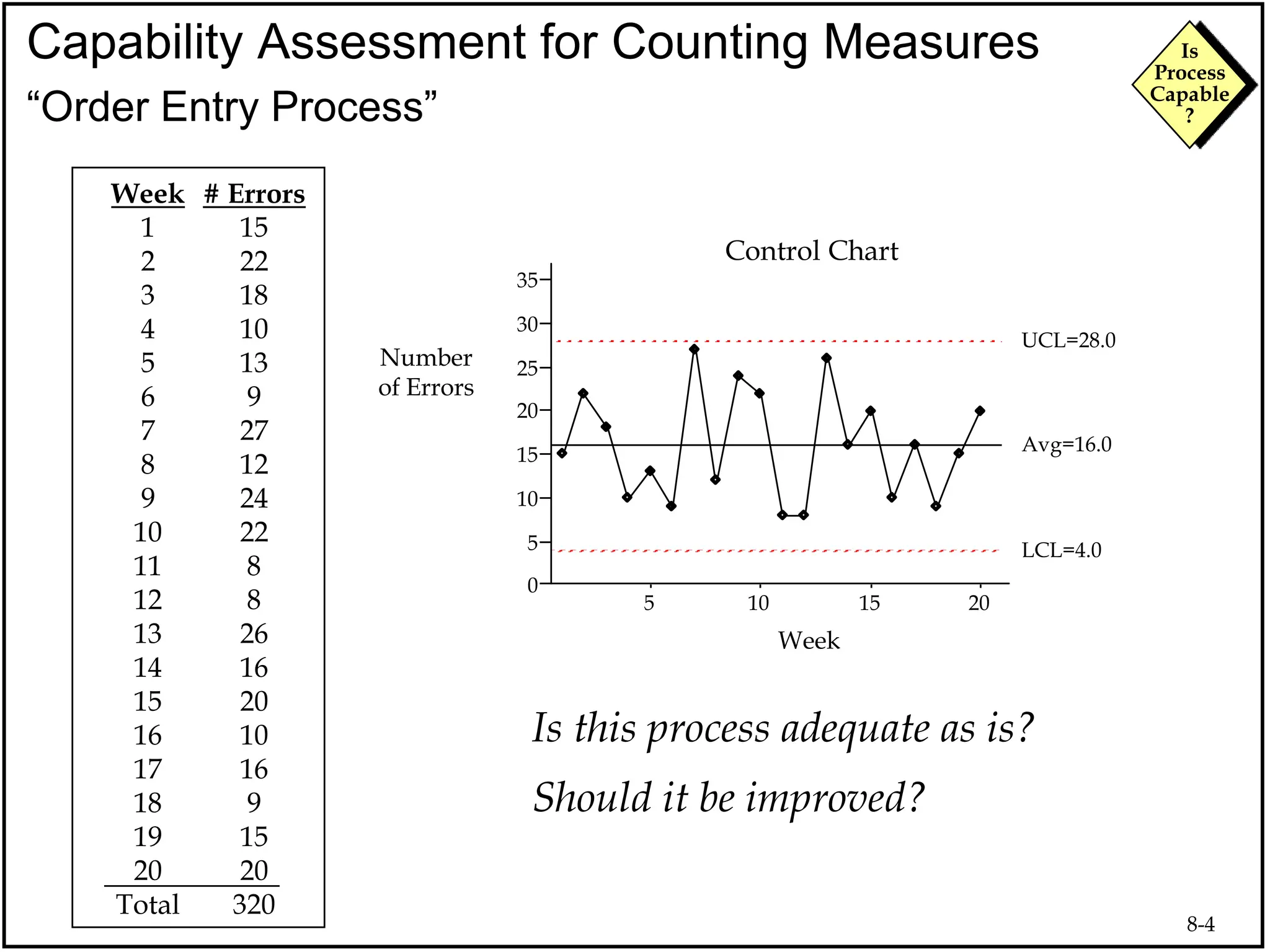

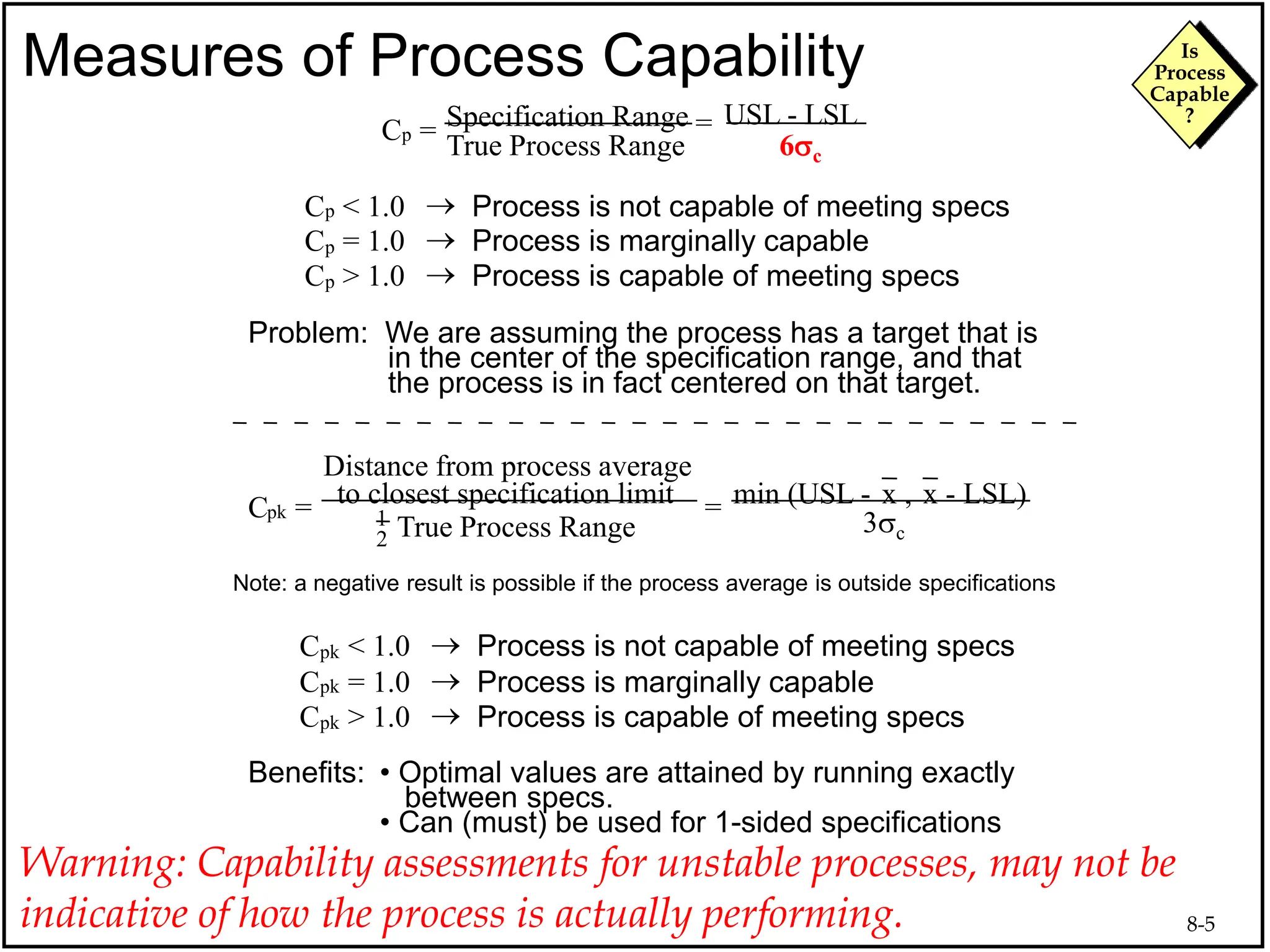

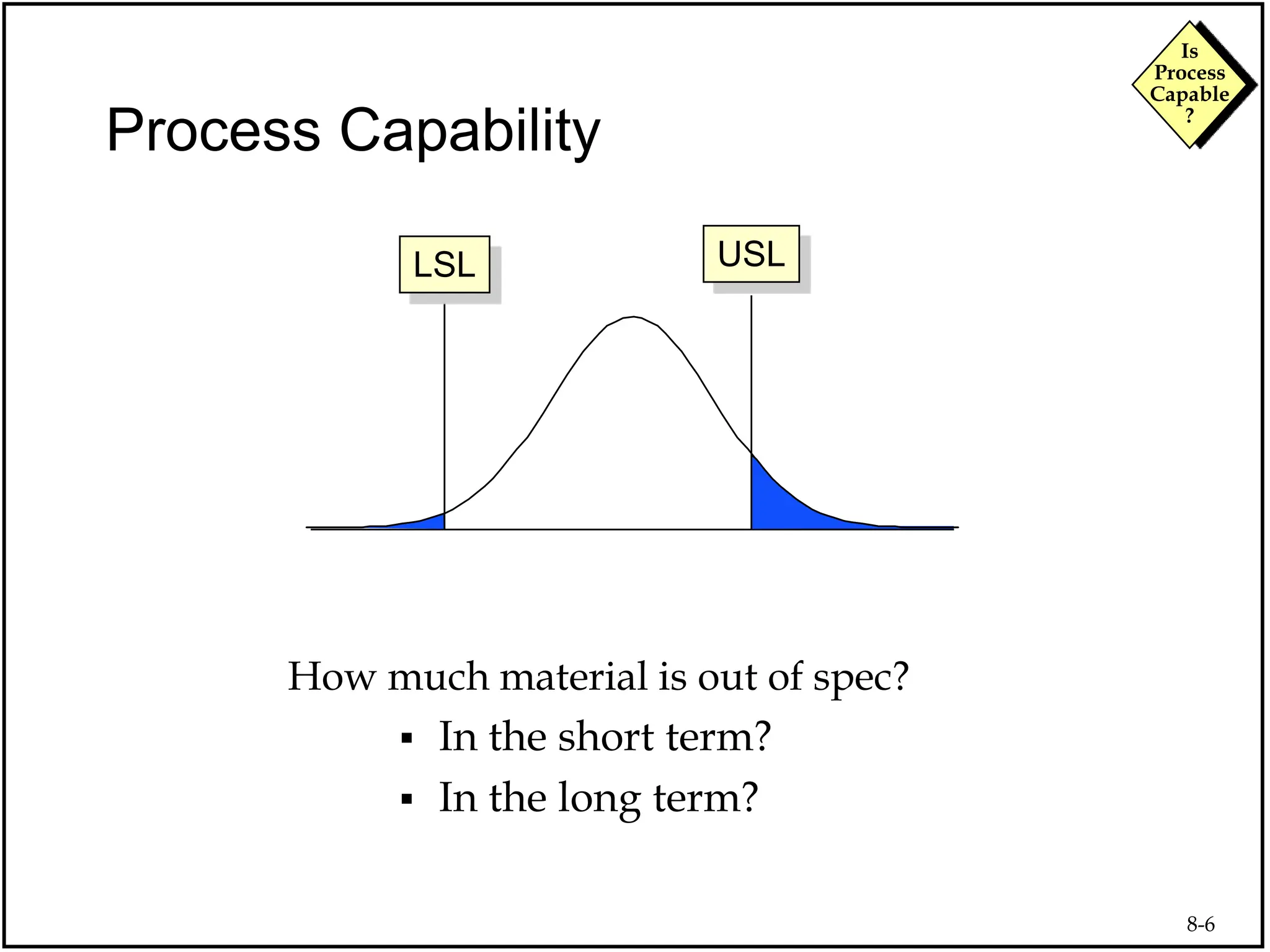

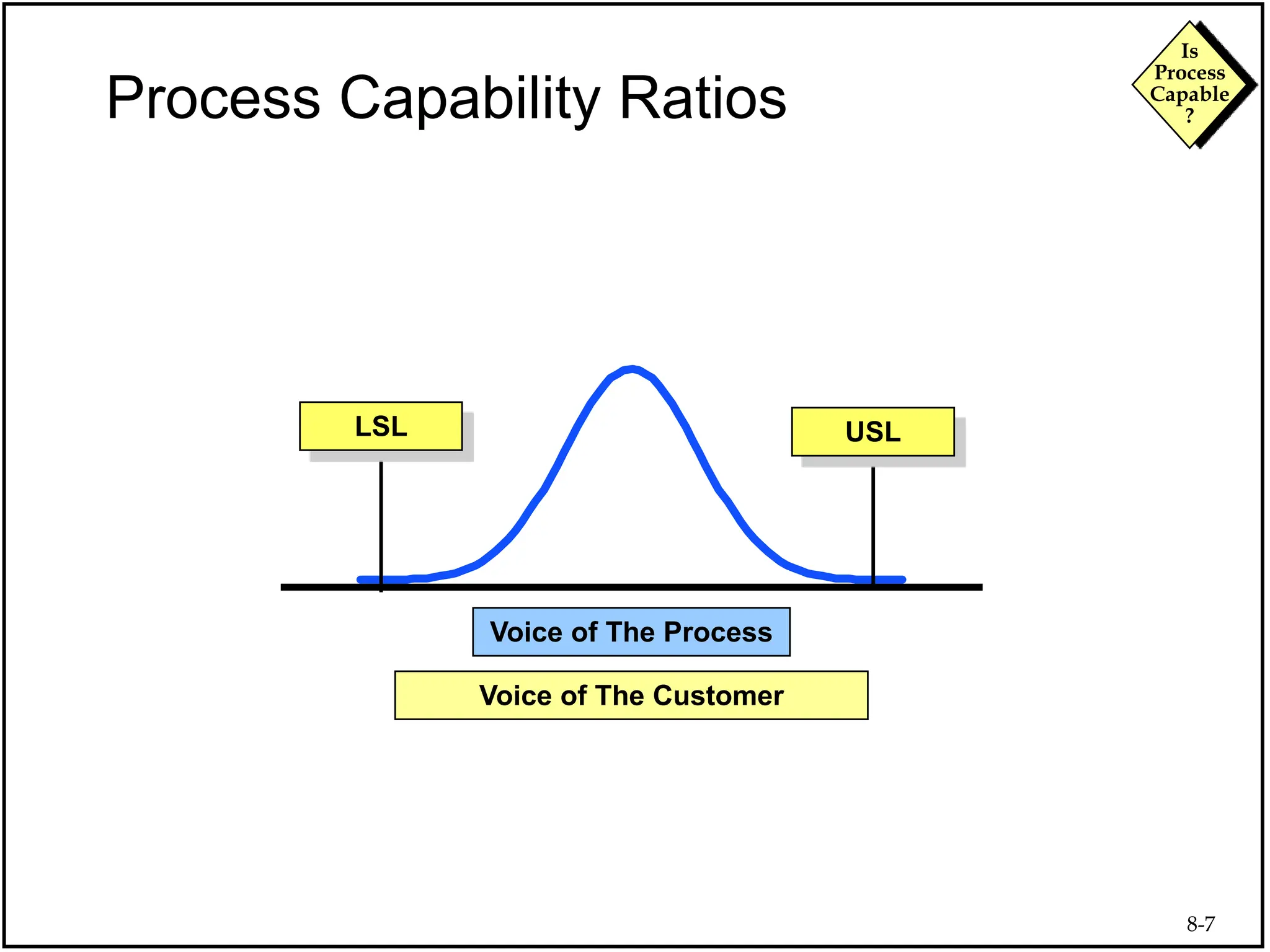

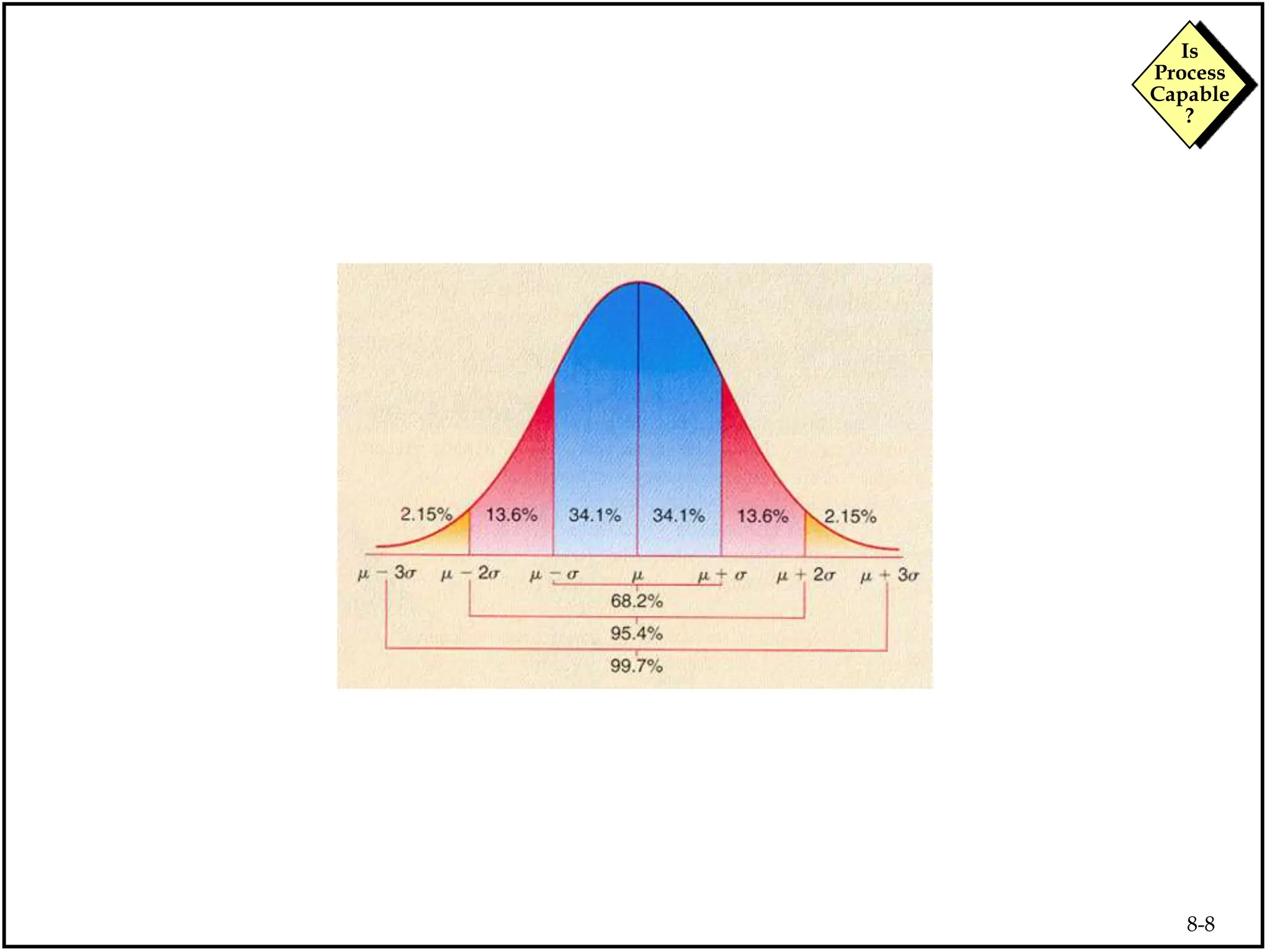

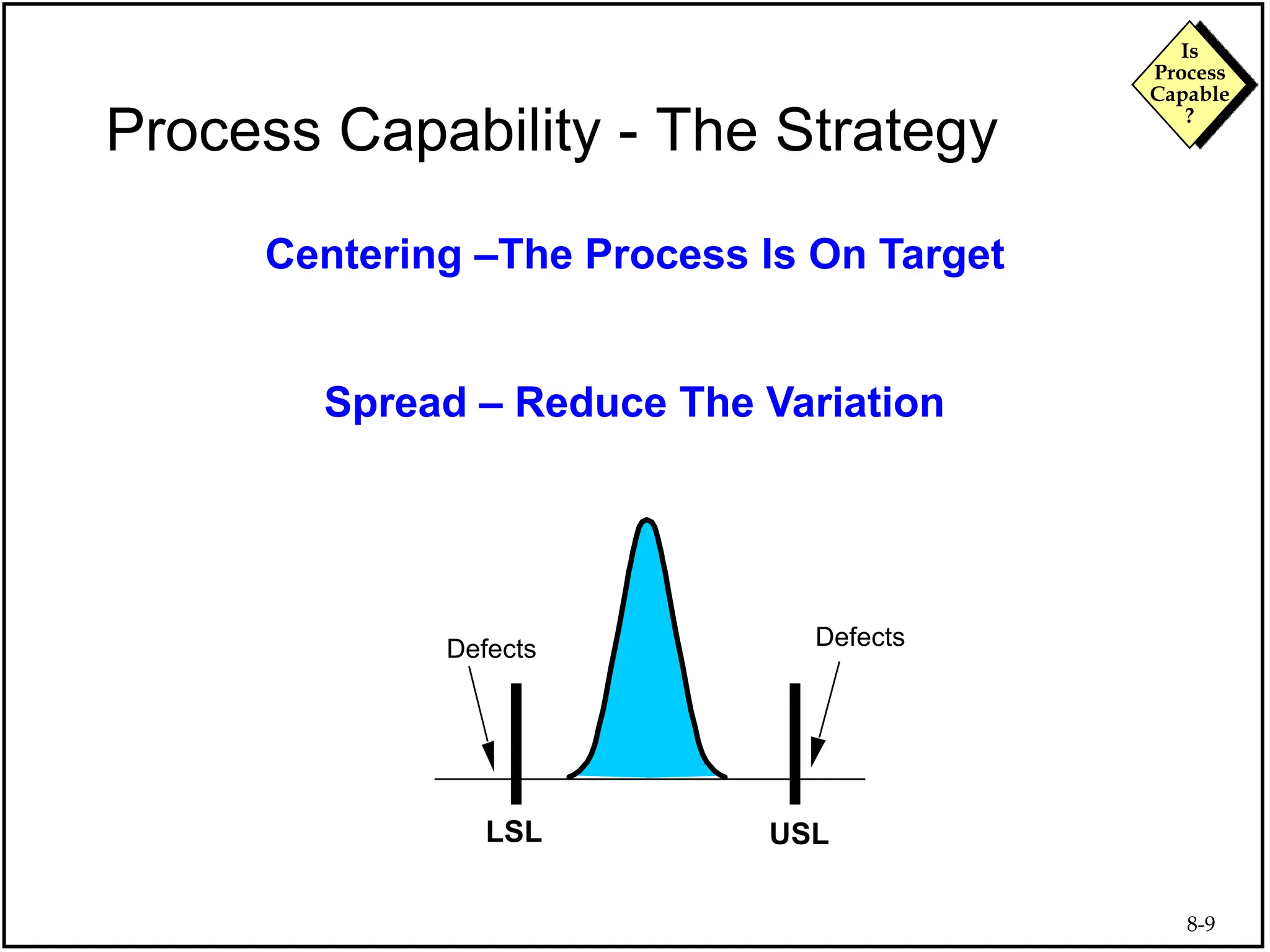

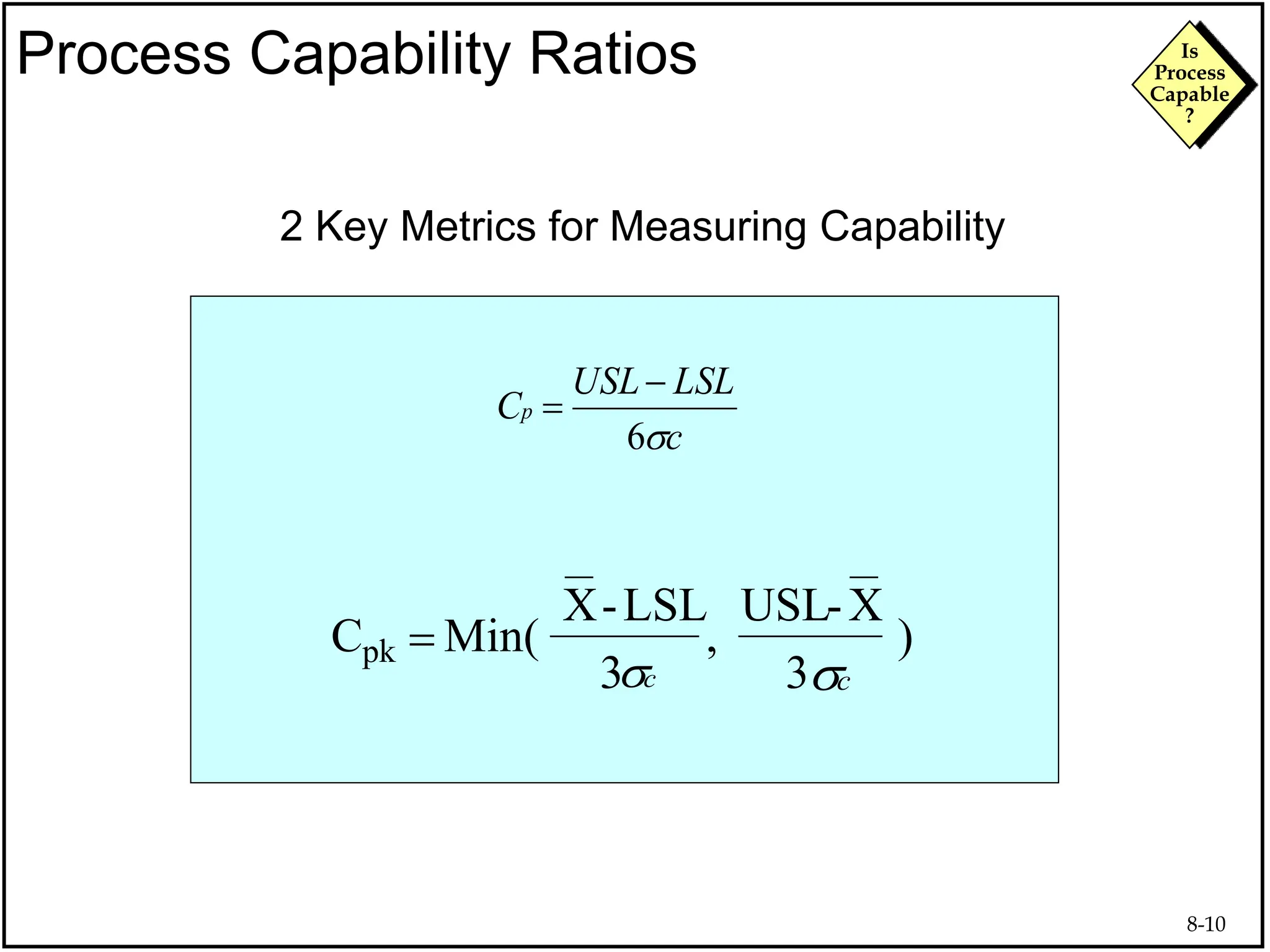

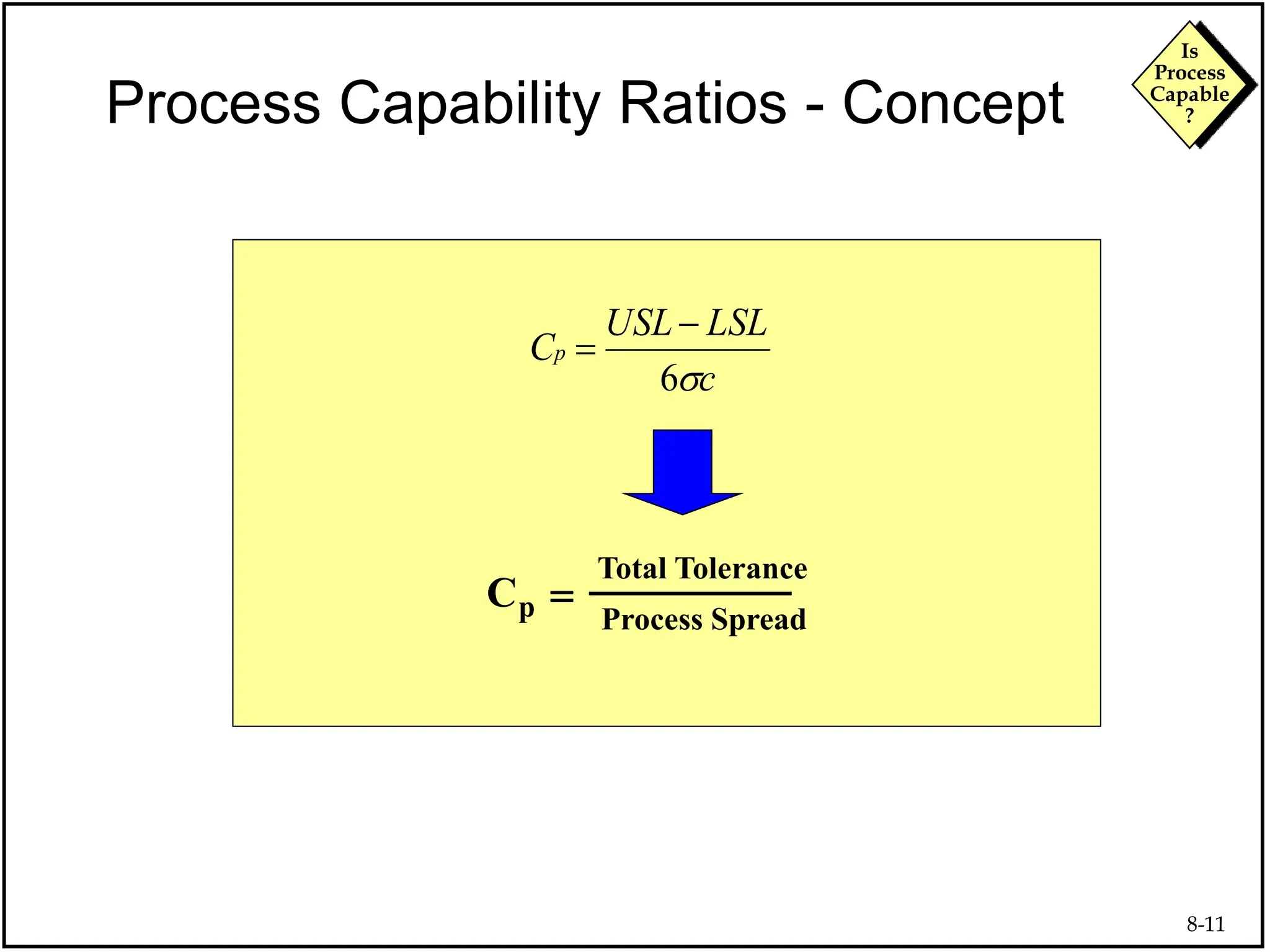

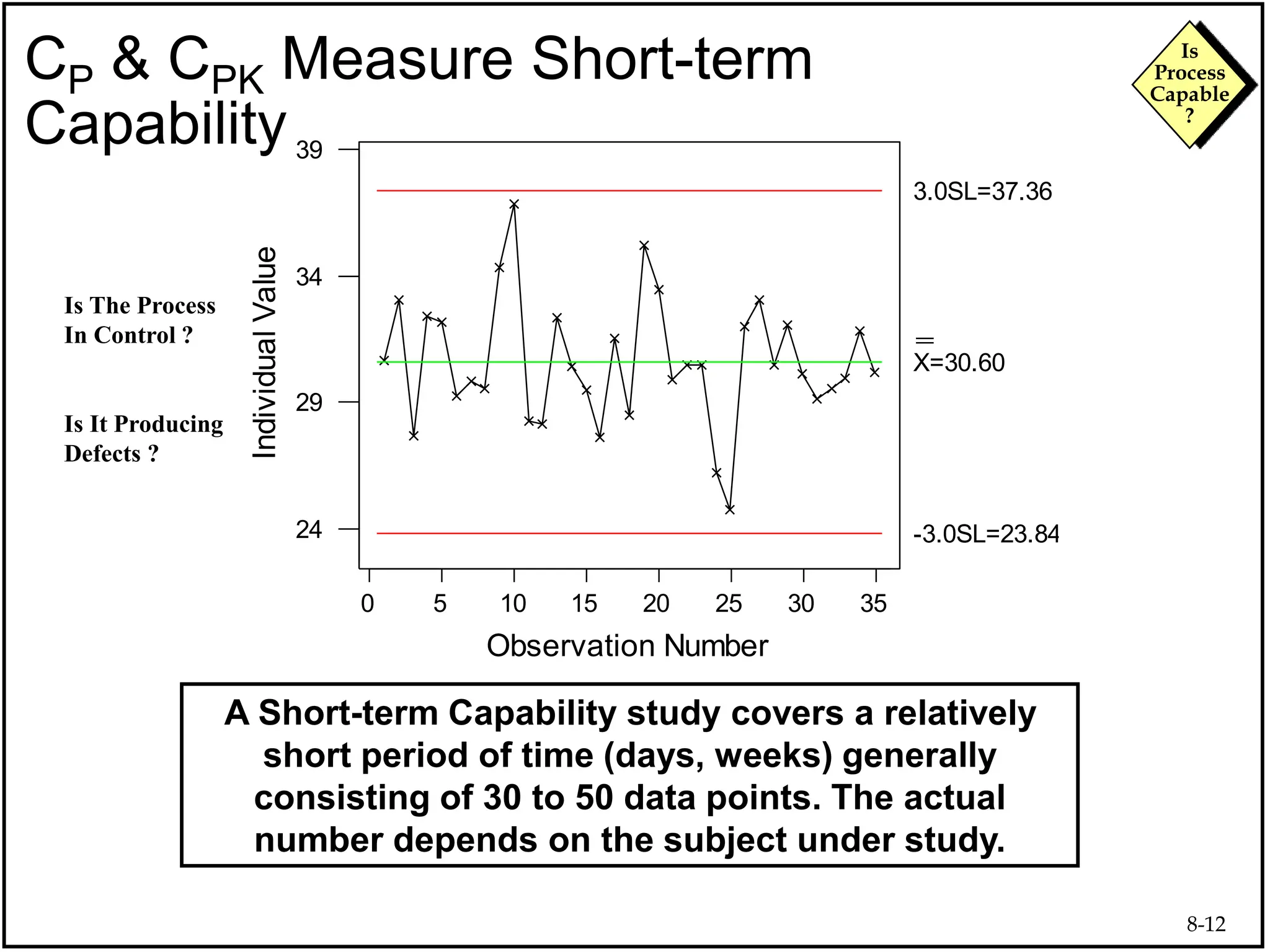

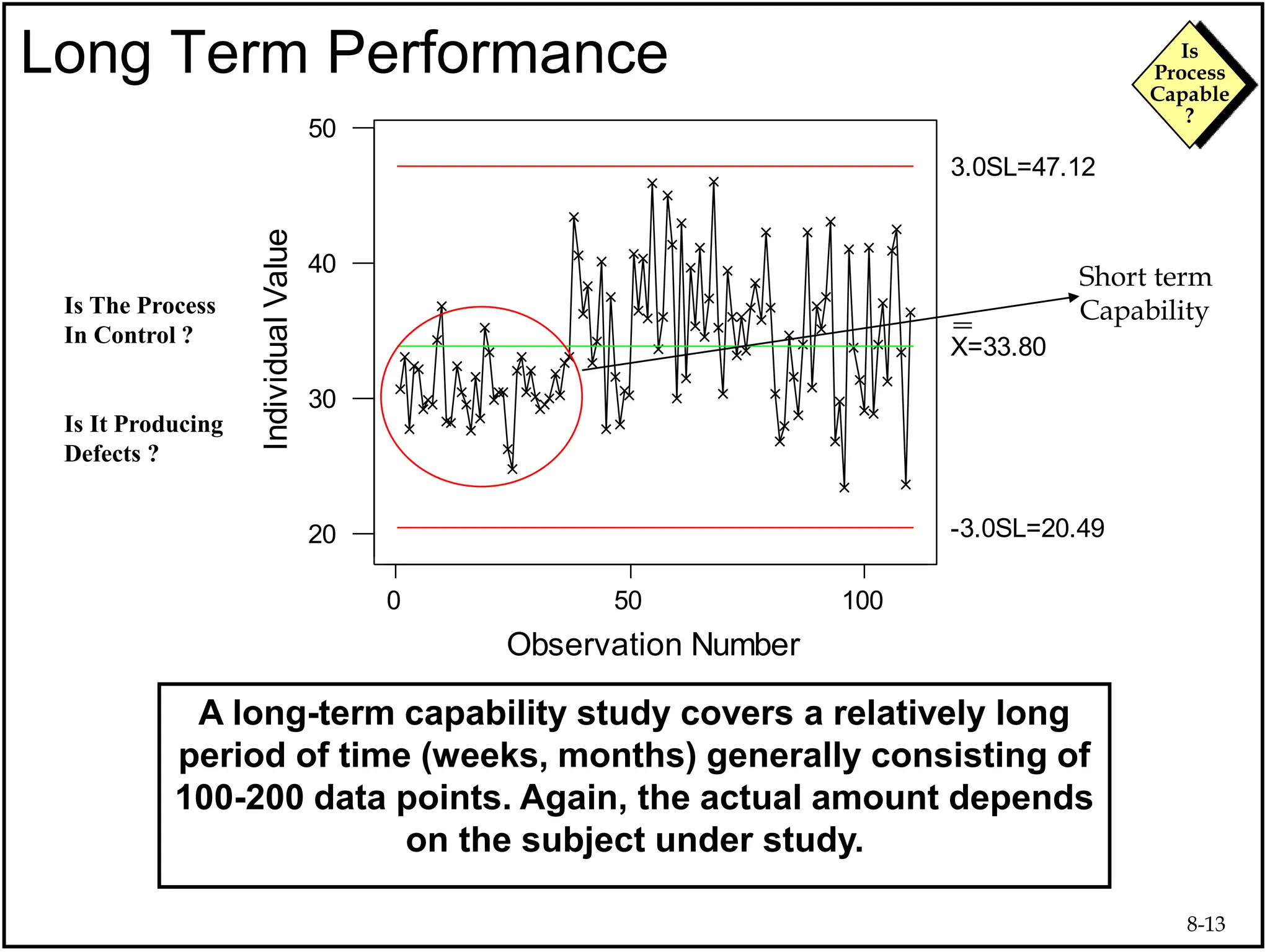

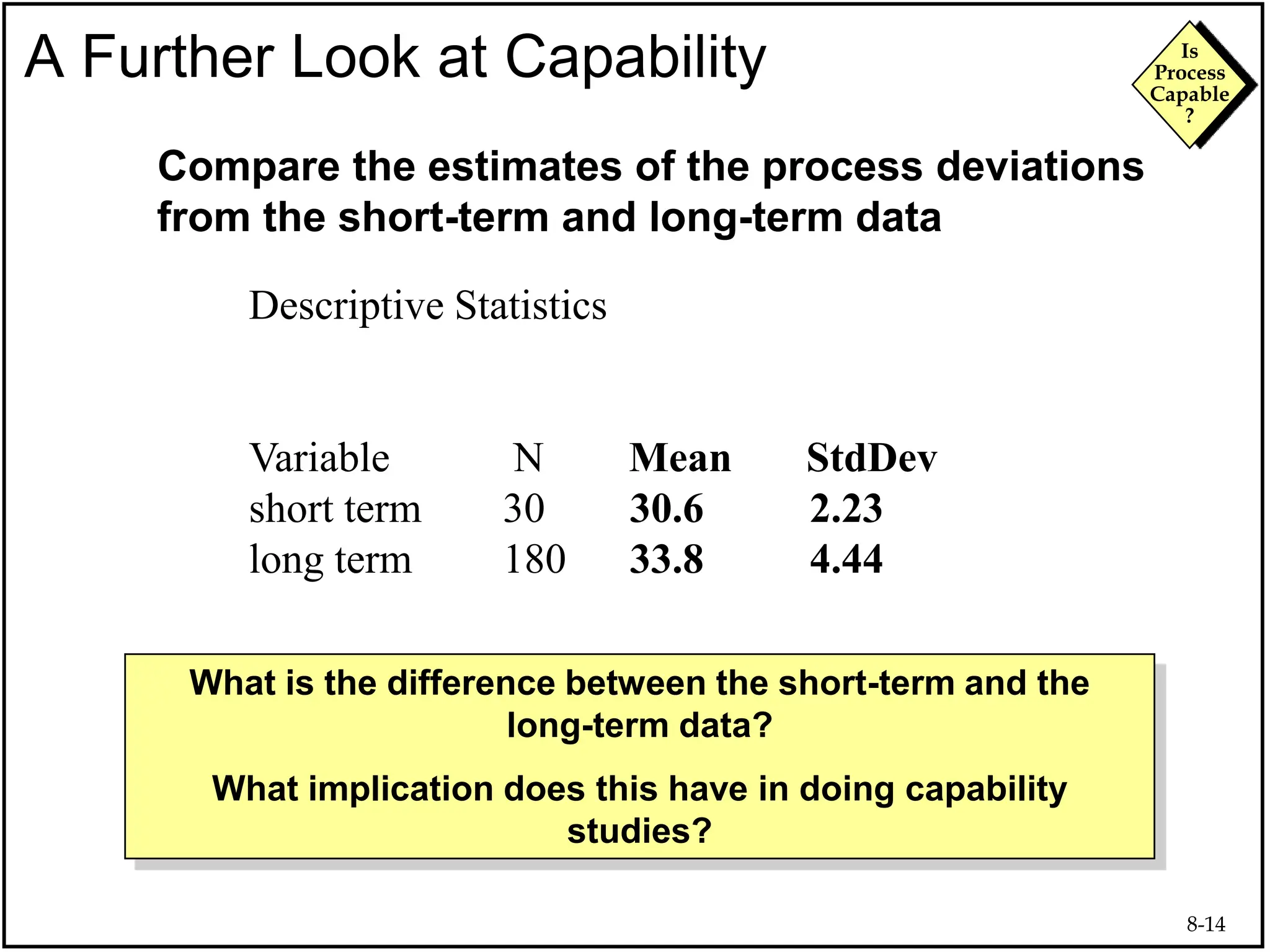

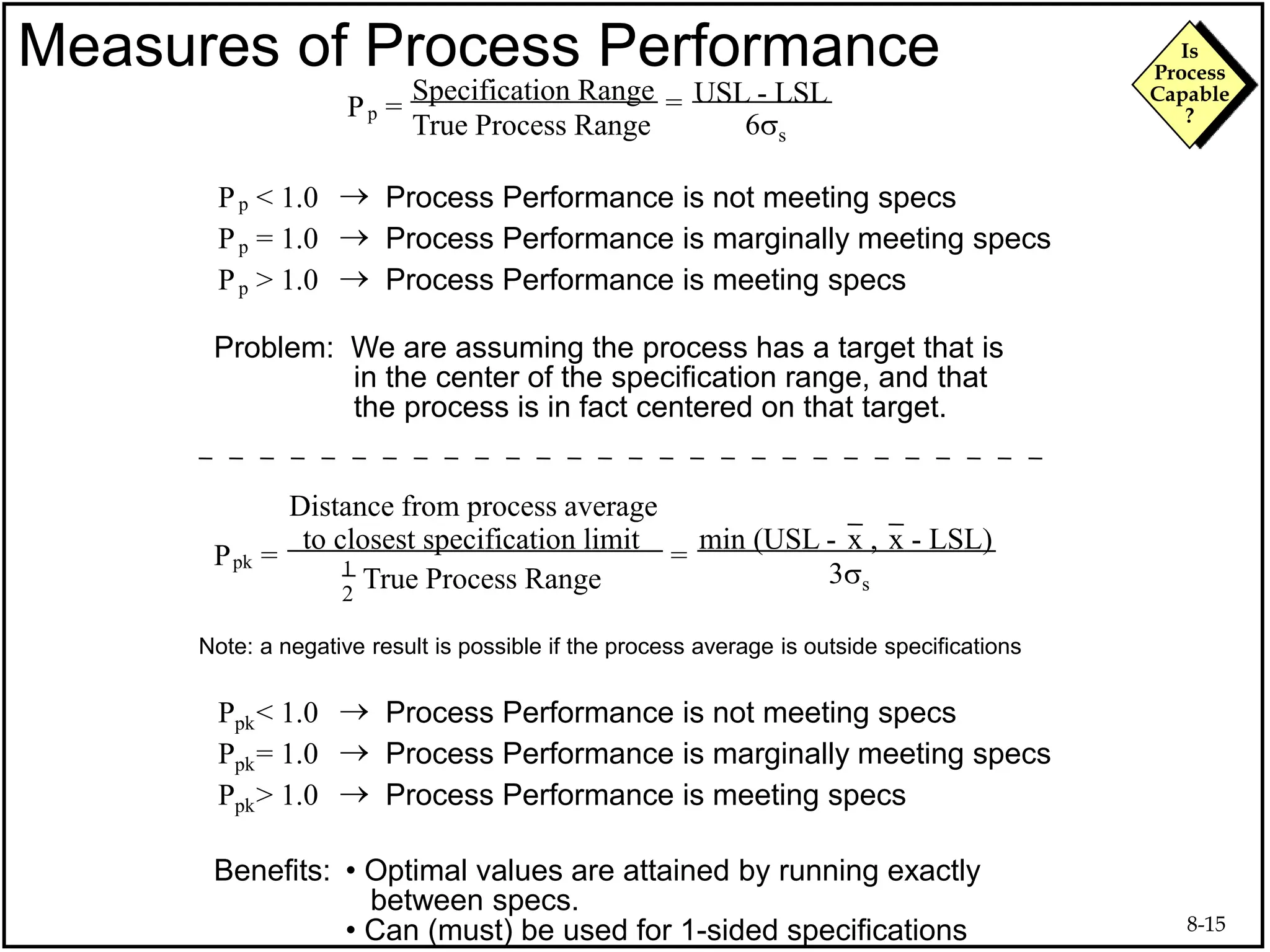

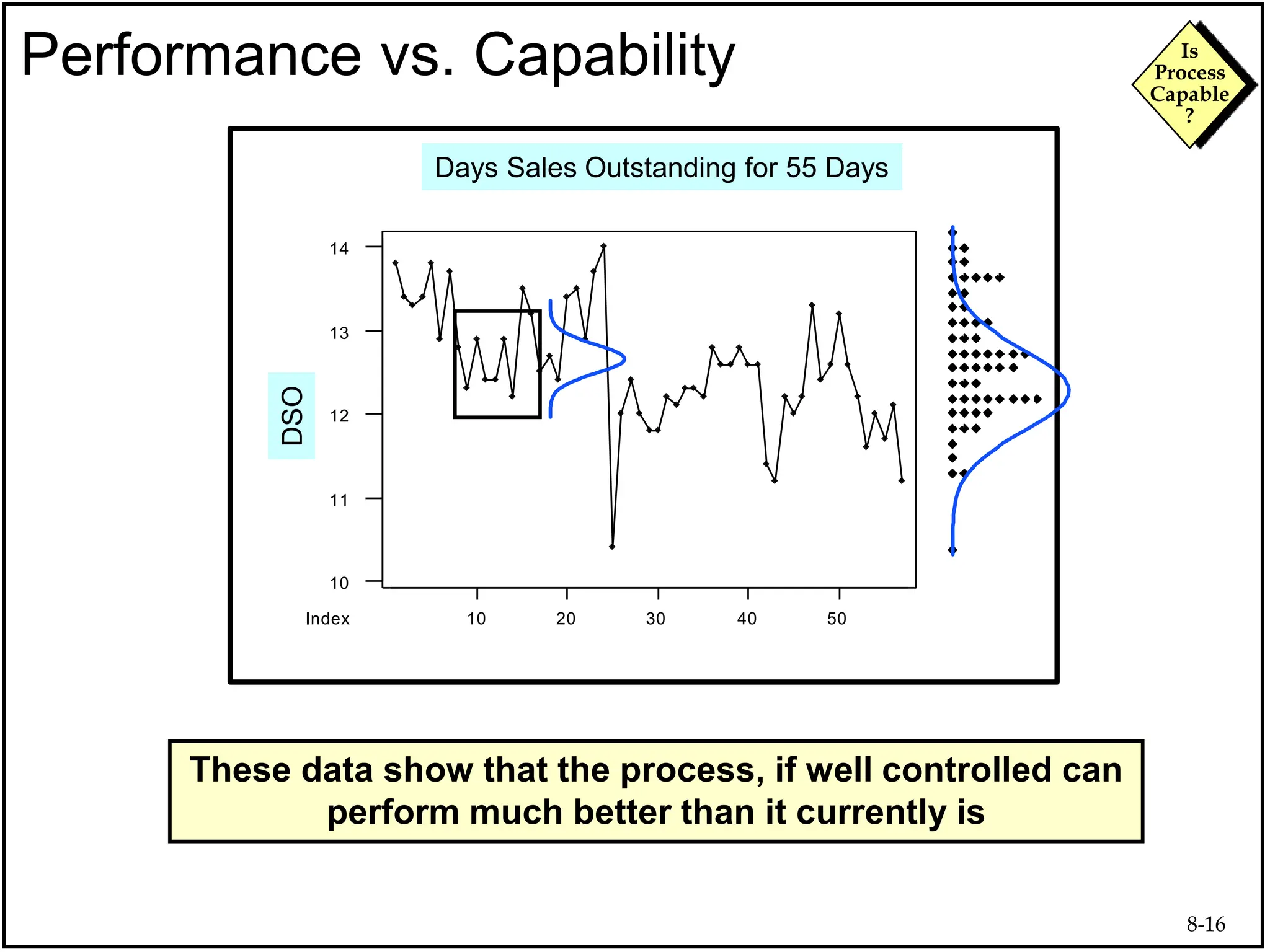

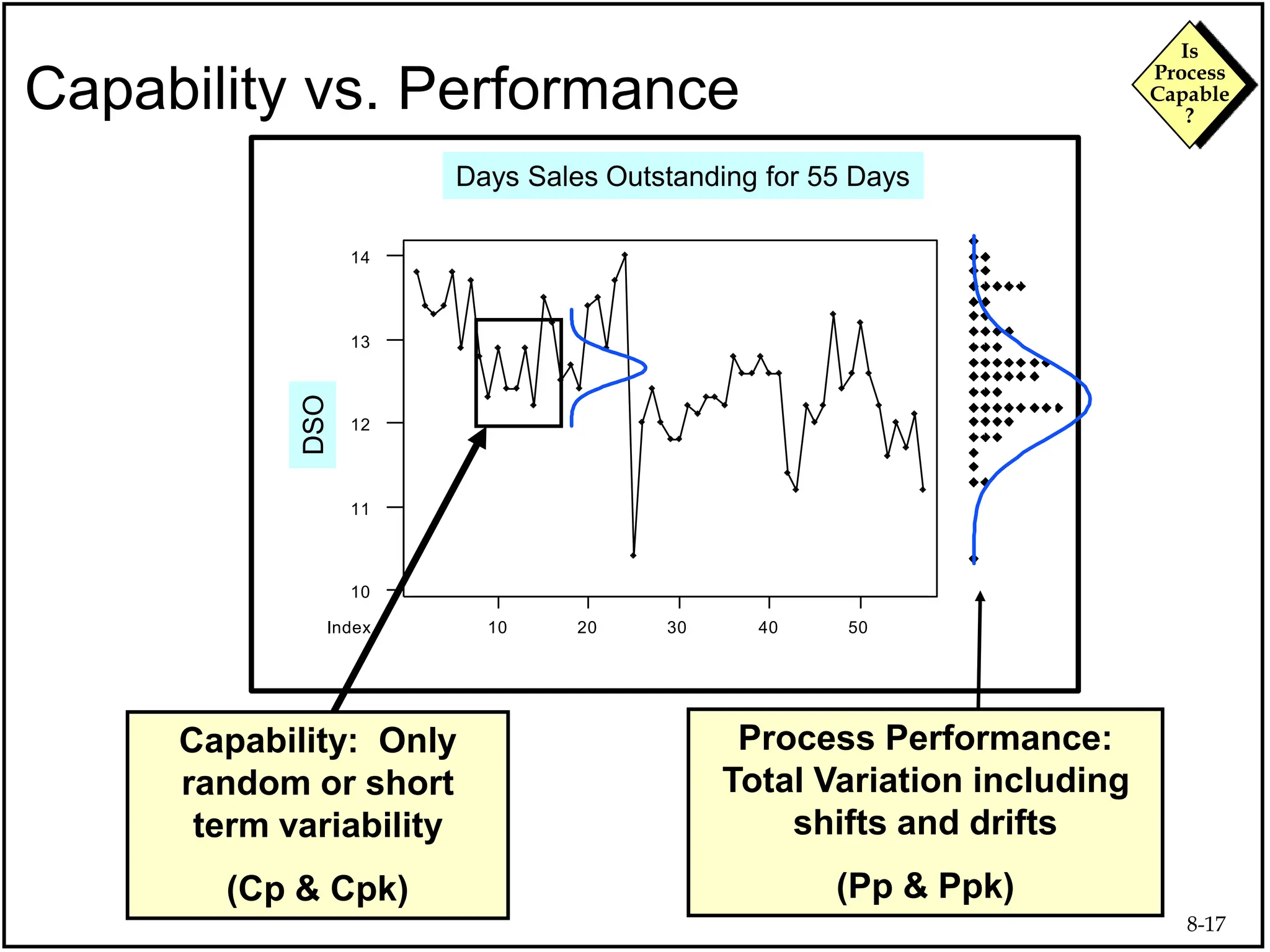

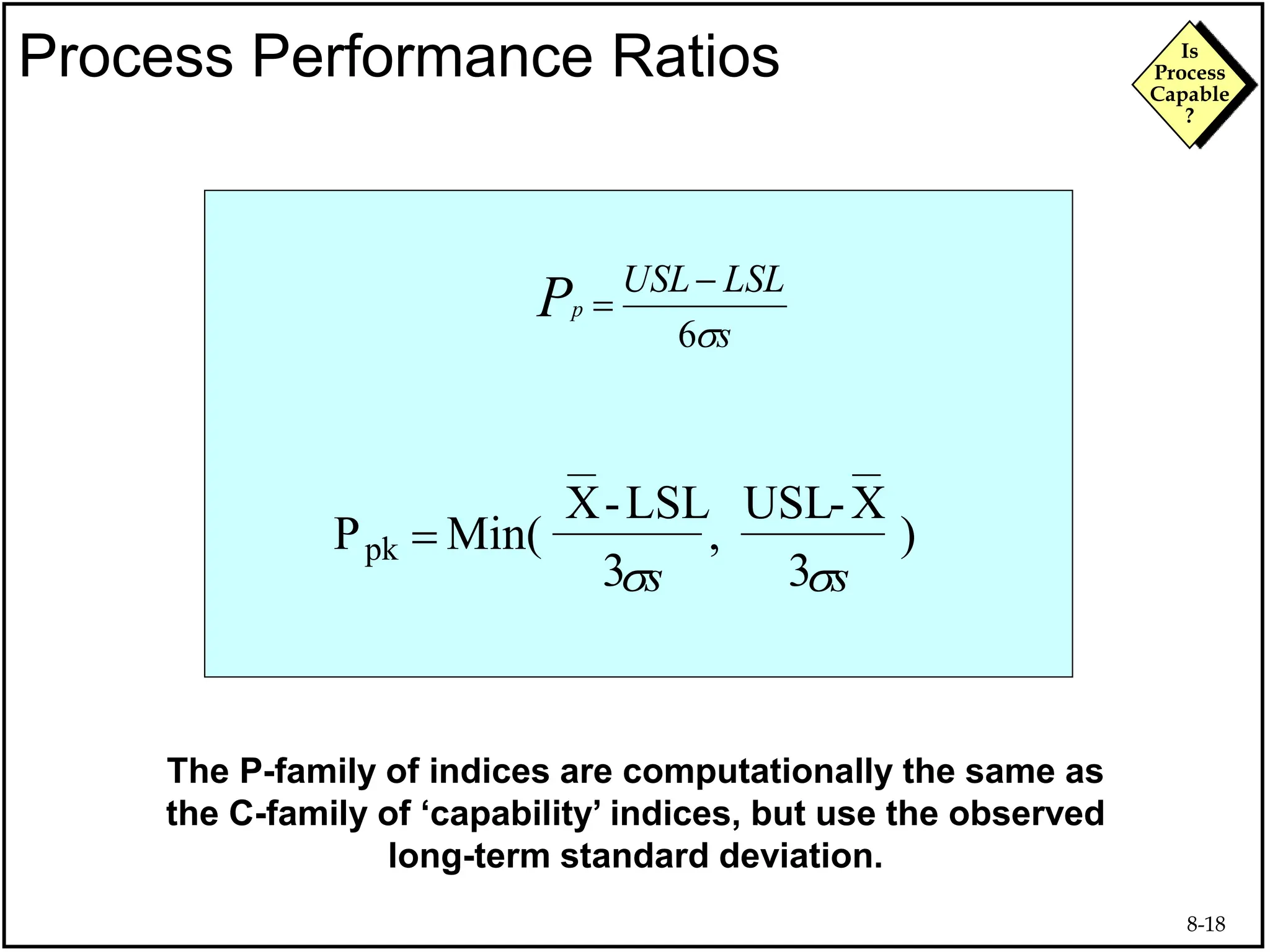

The document outlines a framework for assessing process capability using statistical process control (SPC) measures to determine if processes meet customer requirements and are stable. It emphasizes the importance of understanding short-term and long-term capability metrics, detailing various measurements like Cp, Cpk, Pp, and Ppk, and highlights the necessity of stable processes for accurate assessments. The content warns against the interpretation of capability results for unstable processes and discusses improvement strategies to enhance process capability.