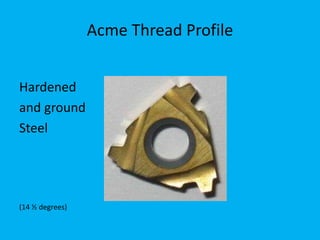

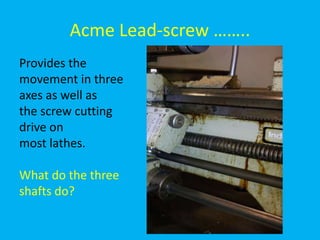

The document discusses backlash in machine tool lead screws. It aims to analyze the materials used for axial movement in manual machinery, specifically lead screws and nuts. It also aims to describe what backlash is in the context of machine tool lead screws. The document identifies that lead screws are typically made of hardened and ground steel to provide movement in three axes. It notes that nuts are often made of brass or bronze and discusses the reasons for these material choices. It also covers the concept of backlash, or wear, that can occur between the lead screw and nut, and how this impacts positioning precision.