More Related Content

Similar to B 1 b-12 f0371b(standard operation procedure)

Similar to B 1 b-12 f0371b(standard operation procedure) (20)

B 1 b-12 f0371b(standard operation procedure)

- 1. 1

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

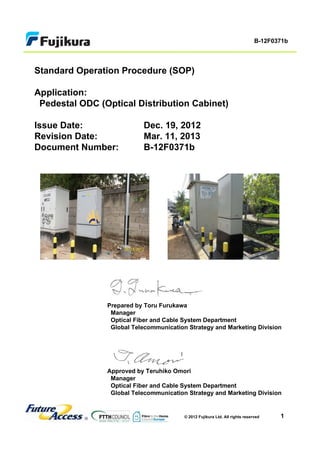

Standard Operation Procedure (SOP)

Application:

Pedestal ODC (Optical Distribution Cabinet)

Issue Date: Dec. 19, 2012

Revision Date: Mar. 11, 2013

Document Number: B-12F0371b

Prepared by Toru Furukawa

Manager

Optical Fiber and Cable System Department

Global Telecommunication Strategy and Marketing Division

Approved by Teruhiko Omori

Manager

Optical Fiber and Cable System Department

Global Telecommunication Strategy and Marketing Division

- 2. 2

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

1. Introduction:

This standard operation procedure (SOP) based on the best practices

has been issued to provide guidelines for the construction and

implementation of FTTH in access network and will help access network

construction staff on how to install pedestal ODC (Optical Distribution

Cabinet) in outside plant (OSP).

2. Application:

This standard operation procedure (SOP) based on the best practices is

to be applied to installation of pedestal ODC (Optical Distribution Cabinet)

in outside plant (OSP). The SOP shall be modified along with national and

regional laws/regulations and the best practices in each country/region.

Feeder Cable Section Distribution Cable Section

Pedestal

ODC

- 3. 3

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

No. Product Description

(Specification / Model No.)

External View

(The Largest One, Example)

Remarks

1 Optical Distribution Cabinet (ODC)

Spec. No. PNJBC-0516-54-03

(1) ODC-C-96 Splitter

(2) ODC-C-144 Splitter

(3) ODC-C-288 Splitter

(4) ODC-C-576 Splitter

ODC-C-576 Splitter (Example):

0.75 m W x 1.45 m H x 0.54 m D

230 kg

2 Passive Splitter (PS), ODC

Spec. No. PNJBC-0516-54-10

(1) PS-1-2-ODC

(2) PS-1-4-ODC

(3) PS-1-8-ODC

(4) PS-1-16-ODC

(5) PS-1-32-ODC

Spec. No. PNJBC-0516-54-11

(6) PS-2-2-ODC

(7) PS-2-4-ODC

(8) PS-2-8-ODC

(9) PS-2-16-ODC

(10) PS-2-32-ODC

PS-1-32-ODC (Example):

18 mm W x 80 mm H x 120 mm D

PS-2-32-ODC (Example):

18 mm W x 80 mm H x 120 mm D

3 Pigtail, 0.9 mm, SC/UPC, 1.2 m

Spec. No. TS1211-01

FJC-T1A-SCUC-1.2

FJC-T1A-SCUC-1.2:

4 Fiber Protection Sleeve

Spec. No. B-05F0040

FP-03

FP-03:

60 mm L x 3.1 mm dia. after Shrink

Preferred.

3. Bill of Materials/Specific Tools:

Table 1. Bill of Materials

- 4. 4

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

No. Product name

(Type)

Exterior Remarks

5 Connector Cleaner

SC-CLK-B¡

SC-CLK-B:

17.5 mm W x 17.5 mm H

x 165* mm L

*200 when nozzle

extended.

-

6 Messenger wire cutter

7 Scissors

8 Nipper

9 Pliers

10 Screw driver ( + )

11 Alcohol

12 Cotton

13 Marker White color

preferred

Table 2 . Specific Tools

*Please prepare necessary tools if needed.

- 6. 6

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

5. Overview of Design Flow:

(1) Decide an installation location.

(2) Select materials.

(3) Decide cabling routes.

(4) Decide hardware/accessories for cabling.

Annex :

Foundation for ODC-C-144 Splitter

Foundation for ODC-C-288 Splitter

- 7. 7

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

6. Overview of Work Flow:

The steps in the installation of the pedestal ODC after the

base/foundation built include the following:

(1) Start:

Prepare work directions (layout documents), manuals and tools.

(2) Unpack:

Unpack crates/boxes with opener/lever.

(3) Check:

Check descriptions and numbers of materials in accordance with

delivery documents.

(4) Carrying:

Take the pedestal ODC, materials and tools to the installation location.

(5) Marking & Drilling / Setting & Positioning:

Place the pedestal ODC on the foundation that has been provided.

(6) Structure Assembling:

Install the bolts/nuts, then stack the pedestal ODC in position and do

leveling to water level so that the pedestal ODC is not skewed.

(7) Related Material Setup:

Set up related materials into the pedestal ODC. Follow the manuals for

the pedestal ODC and related materials.

(8) Cable Laying & Cable Forming:

Lay cables/cordage that connect related materials, not only fiber optic

cables/cordage but also grounding wires to grounding terminals if

applicable, then tie the cables/cordage at cable trays, holders or guides.

Arrange cables/cordage at more than permissible bend radius especially

around the cable tray, holder or guides with ties at an appropriate distance.

- 8. 8

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

(9) Cable Termination:

Terminate cables/cordage in the pedestal ODC in accordance with work

directions (cabling diagram) and attach labels to cables/cordage or record

their connections in the attached sheet to be easily recognizable.

(10) Cabling Check:

Check all cabling connections with test equipment if applicable.

(11) Cleaning:

Clean the installation location and collect the remaining unused materials

for installation to other places.

(12) Finish:

Perform testing/measuring along with commissioning test procedures

and create test reports.

- 9. 9

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

7. General Requirements

General requirements for the pedestal ODC include the following:

(1) If the pedestal ODC is installed close to the intersection, it shall not be

placed too close to the street corner, the minimum distance from the

street corner shall be 5 meters and the distance from the curb shall be at

least 1 meter. Here's an example placement of the pedestal ODC.

Figure: Pedestal ODC Placement at Street Corner

(2) The pedestal ODC has an outdoor cabinet with a cover with/without air

vents and the cover and its air vents shall not be closed with obstacles.

(3) The pedestal ODC shall be mounted securely, not tilted and meet the

aesthetic beauty and come with a good grounding if applicable.

(4) To prevent dirt, dust and animals/insects from going inside, all unused

holes except air vents shall be closed.

(5) If the pedestal ODC shall be placed in the yard of the resident or office

for some reason, it shall obtain prior written permission from the owner.

(6) If there are more than one pedestal ODC in a location, the placement

shall pay attention to operating ease, aesthetics a in a location more than

one outdoor device, placement should pay attention to operating ease,

aesthetics, beauty and comfort.

Unit: Meters

Pedestal ODC

- 10. 10

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

8. Location Requirements:

Location requirements for the pedestal ODC include the following:

(1) The location of the pedestal ODC shall be close to the site/plot

customer groups as much as possible so that the cable pulled towards

customers can be shorter and technical requirements (loss budgets) can

be met.

(2) The location of the pedestal ODC shall not be in a location prone to

landslides or flooding.

(3) The location of the pedestal ODC shall pay attention to the installation

location's city plan as possible widening of roads, construction of public

facilities and so forth.

(4) The location of the pedestal ODC shall be secure from external

disturbances such as vehicular traffic, pedestrians and crime. If the

location needs additional safety, crime-prevention solutions such as

fences or locks may be considered.

(5) Foundation of ODC & Hand hole location is related closely.

Please follow the arrangement below figure:

Figure : Foundation of ODC & Hand hole location

More detail, please see

Annex attached.

- 11. 11

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

9. Above-ground Installation Requirements:

Above-ground installation requirements are as follows:

(1) Cabinet stakes protective toward the pedestal ODC may be considered

so as not to accidentally struck by a vehicle in some specific location and

the stakes may be installed either at the front or at the two sides of the

pedestal ODC for other specific location. The installation of the safety

stakes is as shown below.

Figure: Safety Cabinet Stake

Front View Side View

Cast

Concrete

Cabinet

Foundation

Galvanized Pipes

Diameter 3”

Yellow

Black

Cabinet

Safety stakes may

be installed in some

specific location.

- 12. 12

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

(2) The pedestal ODC shall be mounted on the concrete base/foundation

with minimum depth of 600mm and height of at least 500mm from ground

level. The foundation depth and height may be adjusted along with heavy

loads and capacity of the pedestal ODC. The foundation length and width

may be adjusted along with length and width of the pedestal ODC to be

installed. The foundation above ground level shall be plastered/smoothed

and the top surface of the concrete base shall be sloped so that water

does not stagnate around the pedestal ODC, especially for high flood-

prone areas, the foundation shall be adjusted.

(3) The foundation is made of concrete with a ratio of cement, sand, rock

fragments = 1 : 2 : 3 (example). Please contact the supplier of cement for

the best mix ratio or follow contractors’ best practices. The foundation

size may be adjusted along with the size of the pedestal ODC and the

foundation can be made on the spot or in advance (precast).

Please see "Annex " attached for more detail.

Annex : Foundation for ODC-C-144 Splitter

Foundation for ODC-C-288 Splitter

Foundation for ODC-C-288 Splitter

Foundation for ODC-C-144 Splitter

- 13. 13

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

(3) The foundation is made of concrete with a ratio of cement, sand,

rock fragments = 1 : 2 : 3 (example). Please contact the supplier of

cement for the best mix ratio or follow contractors’ best practices. The

foundation size may be adjusted along with the size of the pedestal

ODC and the foundation can be made on the spot or in advance

(precast).

(4) The bottom of the pedestal ODC (cabinet root) shall be firmly

attached to the concrete foundation with appropriate depth not to close

root/skirt cover as the following cabinet installation image on concrete

base/foundation:

Cabinet

Land

Cabinet Foundation

Not to close the cover

with the foundation.

500

600

Figure: Cabinet Root Installation

- 14. 14

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

(5) The interior of the foundation shall be made hollow and have sufficient

space for laying fiber optic cables, power supply cable and grounding

wires if applicable.

(6) In order to avoid the insect after the cables installed, their cavity

should be closed with seal material/paraffin or so. Please follow

contractors’ best practices.

(7) For the convenience of operating personnel, made cabinet shop floor

on site if possible. The size of the working floor may have length 150 cm

and width 135 cm and it can be adapted to the situation on the ground. An

example of the image for the work floor space at the site is the following.

Figure: Example of Work Floor Space

- 15. 15

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

10. Block Diagram of Pedestal ODC:

The block diagram of the pedestal ODC is shown as follows:

Figure: Block Diagram of Pedestal ODC

11. Physical Configuration (Example) of Pedestal ODC:

The physical configuration (example) of the pedestal ODC is shown as

follows:

Figure: Physical Configuration (Example) of Pedestal ODC

- 16. 16

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

Feeder Cable

Distribution Cable

Feeder Cable

Feeder Cable

Termination

Distribution Cable

Termination

12. Cable Termination (Example) of Pedestal ODC:

The cable termination (example) of the pedestal ODC is shown as

follows:

Figure: Cable Termination (Example) of Pedestal ODC

- 17. 17

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

13. Feeder and Distribution Cabling (Example) of Pedestal ODC:

The feeder and distribution cabling (example) of the pedestal ODC is

shown as follows.

P-to-P PON Distribution

(if applicable)

Figure: Feeder and Distribution Cabling (Example) of Pedestal ODC

14. Cabling in Hand Hole:

The cabling in hand hole for the pedestal ODC is shown as follows.

Figure: Cabling in Hand Hole

- 18. 18

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

15. Final Configuration of Pedestal ODC:

The final configuration of the pedestal ODC is shown as follows.

Figure: Final Configuration of Pedestal ODC

Not to close the cover

with the foundation.

Front View Side View

Cast

Concrete

Cabinet

Foundation

Galvanized Pipes

Diameter 3”

Yellow

Black

Cabinet

Safety stakes may

be installed in some

specific location.

Permissible tensile strength and bending

radius shall be considered during and after

installation along with cable specifications.

Cabinet

Land

Cabinet Foundation

500

600

- 19. 19

B-12F0371b

© 2012 Fujikura Ltd. All rights reserved

16. Safety Precautions and Best Practices:

Safety Glasses:

Safety glasses for eye protection should be worn when handling

chemicals, bare fibers, cordage and fiber optic cables.

Chemicals:

Chemicals for cleaning should be handled with care along with health,

safety and environmental instructions on suppliers’ instructions and

material safety data sheets, your company’s instructions and regional

regulations.

FAST connectors and mechanical splice (if applicable) contain index

matching gel. It may be ignited by heat, sparks or flames. Contact with

eyes may cause irritation. Prolonged and/or repeated skin contact may

result in mild irritation or redness.

Upon eye contact, immediately flush eyes with plenty of water for at least

15 minutes as first aid measures and get immediate medical attention.

Upon skin contact, wash off with soap and water as first aid measures and

get medical attention if symptoms occur.

Please contact us for more details.

Bare Fiber Handling:

Cleaved or broken glass fibers are sharp and can pierce the skin or

damage the eyes. Use tweezers when handling pieces of glass fibers.

Recommend to use a fiber cleaver with a fiber scrap collector.

Fiber/Cable Handling:

Optical fiber and fiber optic cable may be damaged by excessive forces.

Please contact suppliers for proper handling.

Laser Safety:

Never look directly into the end of a fiber and connector. Laser light that

may be invisible can damage your eyes.

Cleanliness of Fiber Optic Connectors:

One of failure cases of fiber optic connectors is caused by

contaminations on connector end-face. They could result in worse

insertion/return loss and failure of the end-face. Recommend to clean the

end-face of connector before mating as one of the best practices.