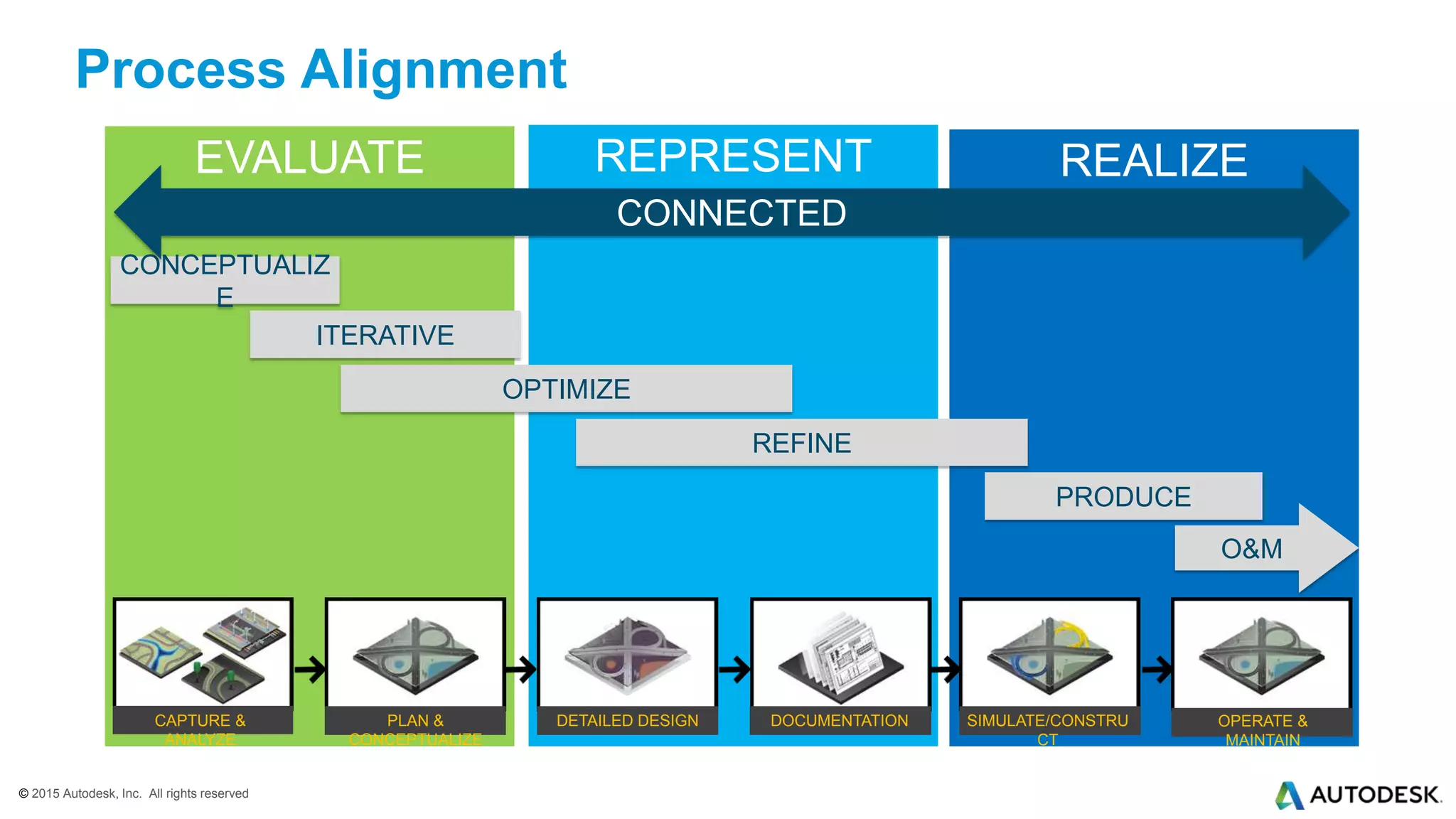

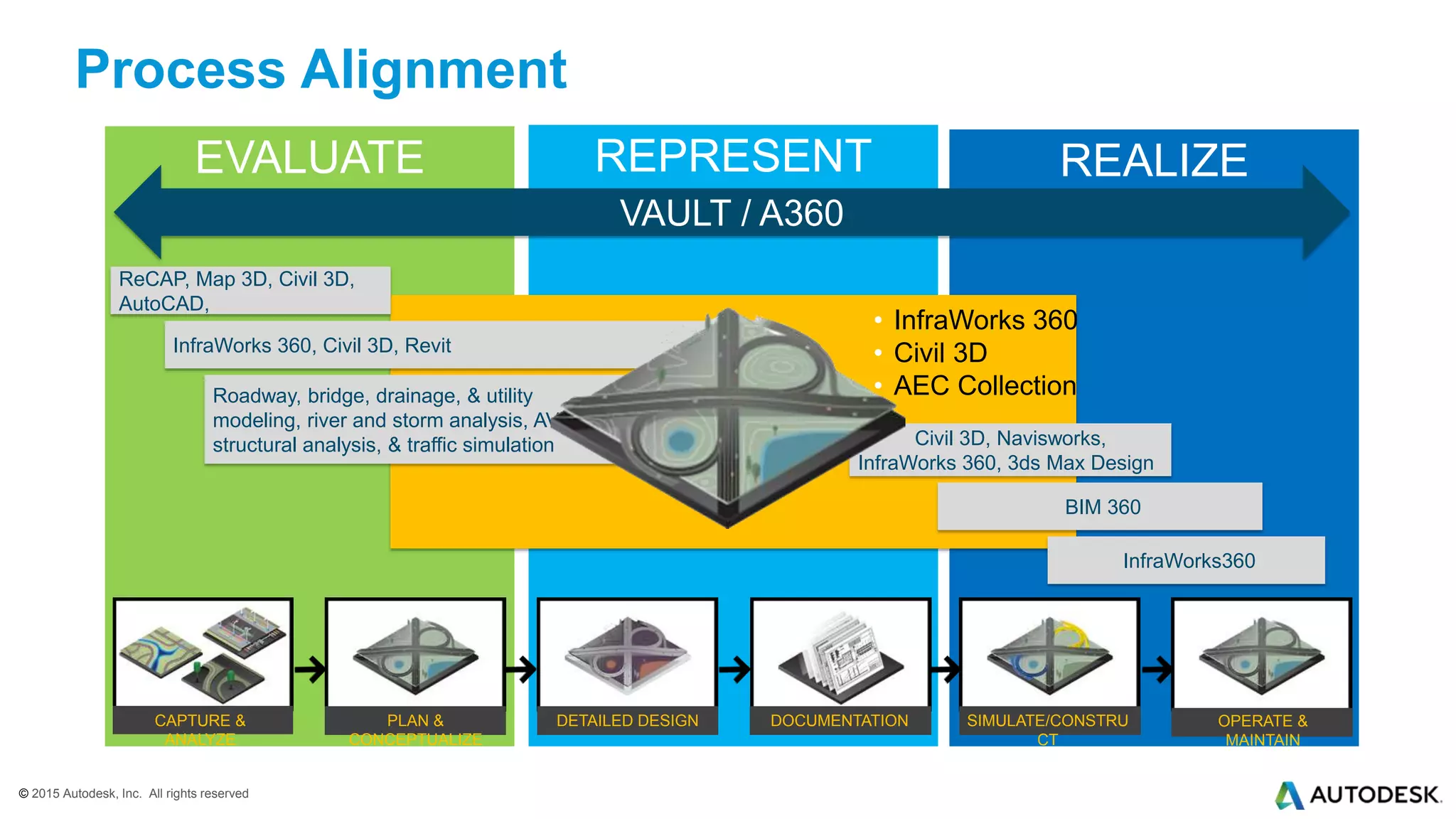

Документ представляет собой обзор технологических революций в проектировании объектов инфраструктуры, выделяя три ключевые эры: документации, оптимизации и соединенных систем. Он подчеркивает текущие вызовы в индустрии, такие как увеличение размера и сложности проектов, а также важность гибкой коммуникации между участниками. Кроме того, представлены технологии и методы, способствующие трансформации процессов проектирования и строительства.