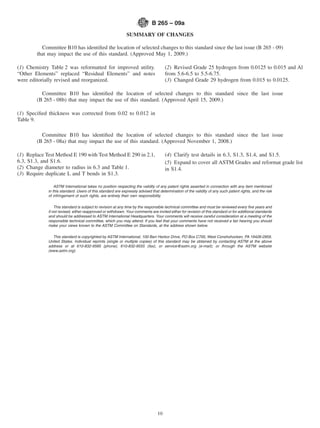

The document is the ASTM B 265 - 09a standard specification for titanium and titanium alloy strip, sheet, and plate, which details various grades and their chemical compositions. It establishes guidelines for mechanical properties, testing methods, and dimensional tolerances relevant to the materials covered. This standard has been approved for use by the Department of Defense and includes specific requirements for different grades of titanium alloys.