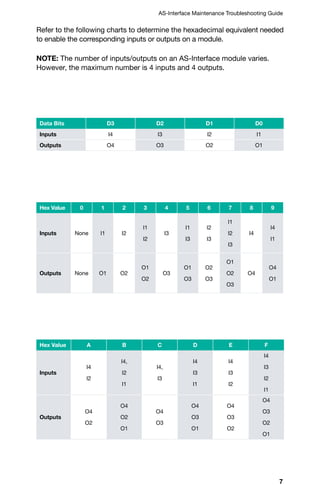

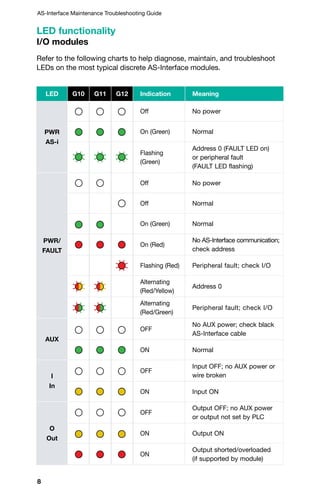

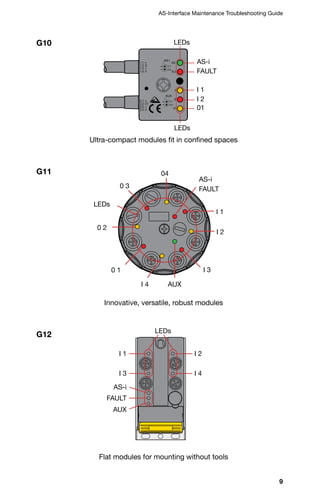

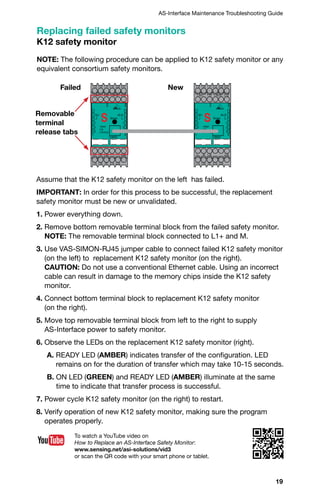

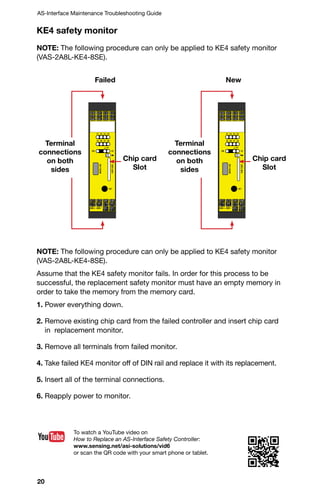

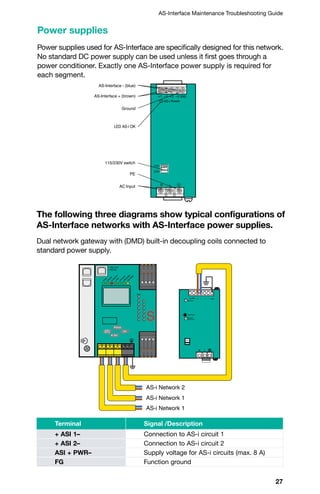

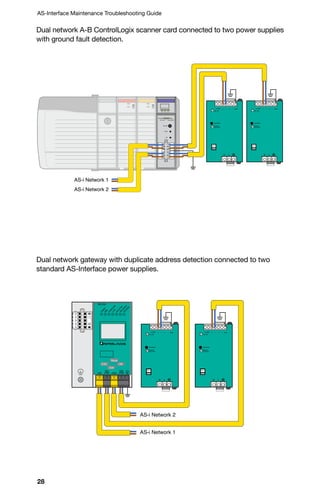

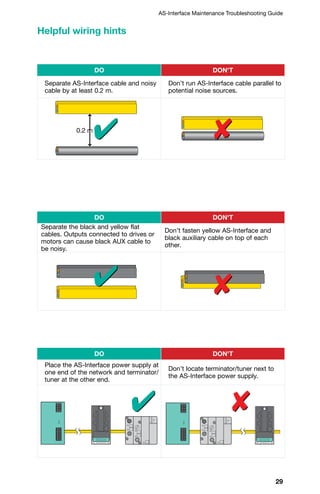

The document provides troubleshooting and maintenance guidance for AS-Interface networks. It includes instructions for using an AS-Interface handheld programmer to set module addresses, read profiles and I/O, and replace failed modules. LED functions are described for various AS-Interface components like I/O modules, safety monitors, and gateways. Common error codes for gateways are explained and steps are provided to resolve configuration errors. Procedures are outlined for replacing single failed safety modules configured in safety monitors.