The document is a service manual for an LG Mini Hi-Fi System model RAT375. It contains sections on safety precautions for servicing the unit, ESD precautions, specifications for the unit, exploded views of parts, and electrical diagrams. The manual provides guidance on servicing the unit safely and properly as well as replacing parts. It aims to prevent damage from electrostatic discharge or other hazards during repair.

![1-1

[CONTENTS]

SECTION 1. GENERAL

• SERVICING PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

• ESD PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

• SERVICE INFORMATION FOR EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

• PROGRAM DOWNLOAD GUIDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

• SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

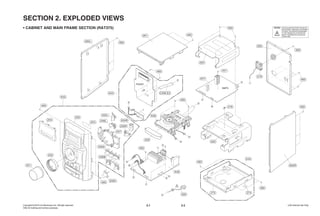

SECTION 2. EXPLODED VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

• CABINET AND MAIN FRAME SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

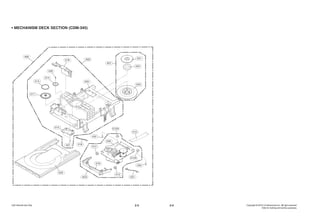

• MECHANISM DECK SECTION (CDM-345). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

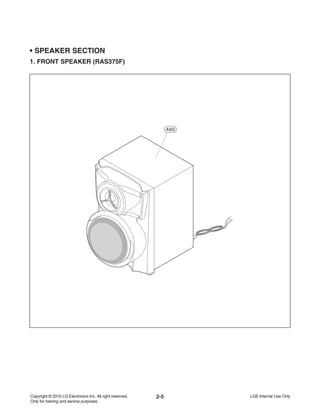

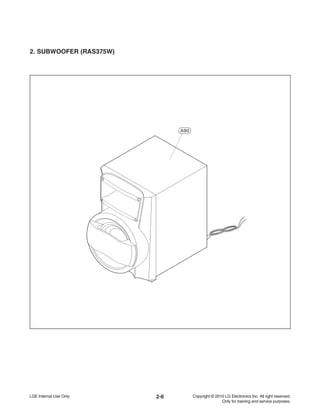

• SPEAKER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

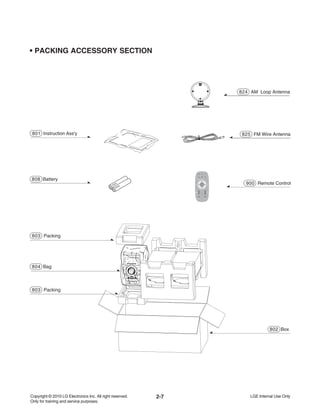

• PACKING ACCESSORY SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

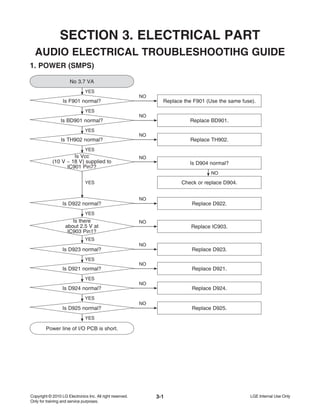

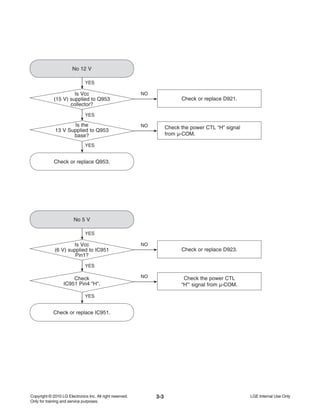

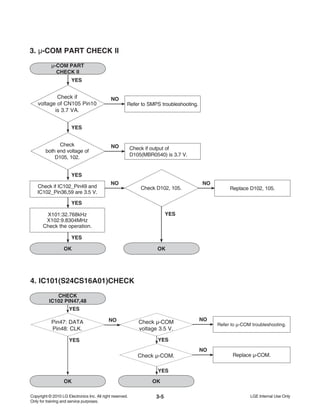

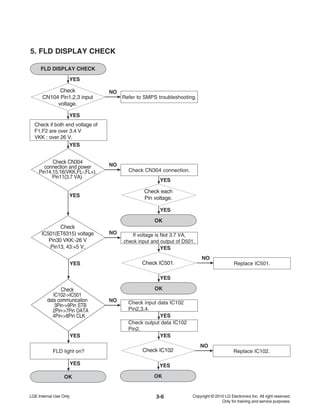

SECTION 3. ELECTRICAL PART

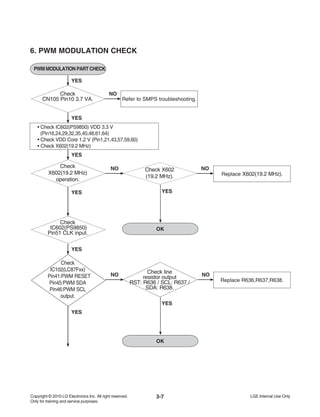

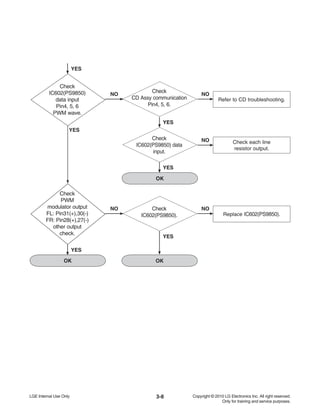

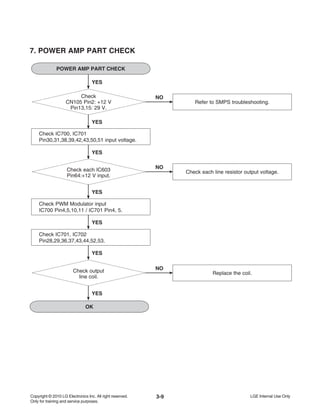

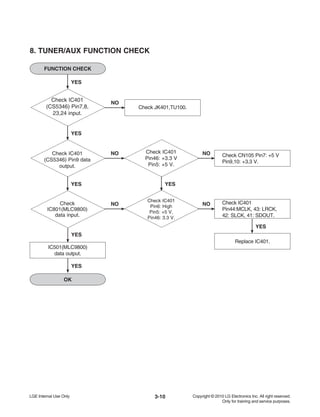

• TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

• DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING. . . . . . . . . . . . . . . 3-14

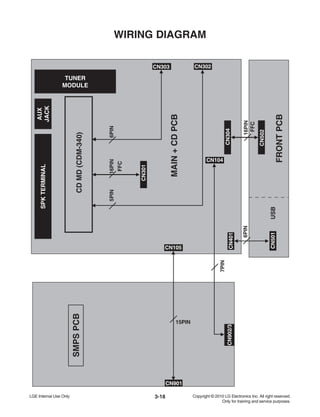

• WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

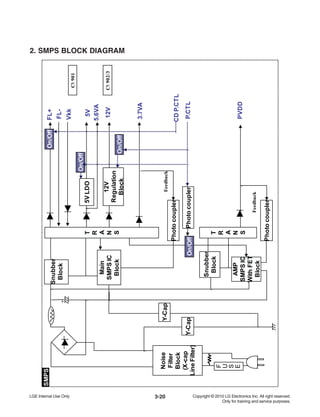

• BLOCK DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

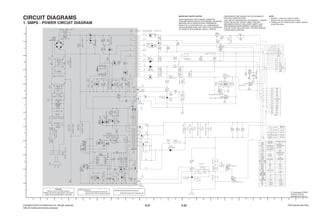

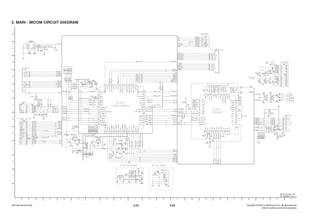

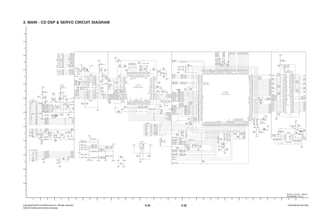

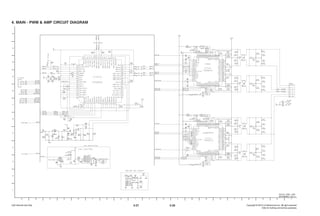

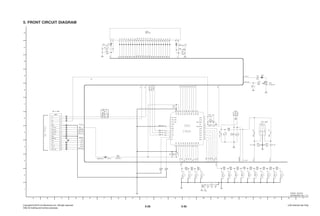

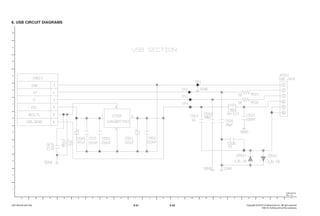

• CIRCUIT DIAGRAMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

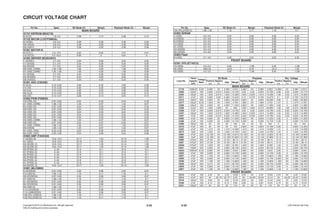

• CIRCUIT VOLTAGE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

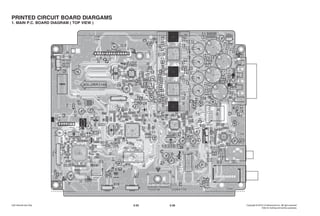

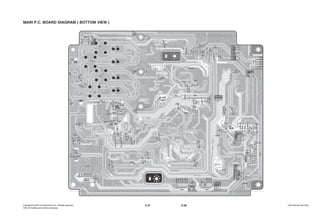

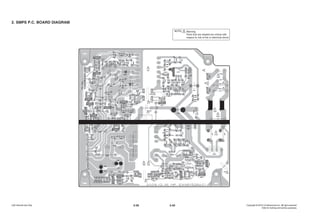

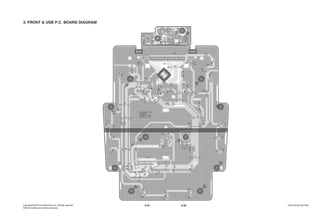

• PRINTED CIRCUIT DIARGAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

SECTION 4. REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1](https://image.slidesharecdn.com/lg-rat375b-141222222237-conversion-gate02/85/LG-RAT375B-2-320.jpg)

![1-8

SPECIFICATIONS

• GENERAL

Power supply Refer to main label

Power consumption 60 W

Net Weight 3.5 kg

External dimensions (W x H x D) 202 x 307 x 278 mm

Bus Power Supply (USB) DC 5 V 500 mA

Operating conditions Temperature 5 °C ~ 35 °C,

Operation status: Horizontal

Operating humidity 5 % ~ 85 %

Laser Semiconductor laser, wavelength 650 nm

• TUNER FM/AM [MW]

FM Tuning Range (87.5 ~ 108.0) MHz or (87.50 ~ 108.00) MHz

FM Intermediate Frequency 128 kHz

AM Tuning Range (522 ~ 1 620) kHz, (520 ~ 1 710) kHz or

(522 ~ 1 710) kHz

AM Intermediate Frequency 45 kHz

• AMPLIFIER

Output Power Front : 110 W + 110 W (4 Ω at 1 kHz, THD 10 %)

Sub Woofer : 150 W (3 Ω at 60 Hz, THD 10 %)

• CD

Frequency Response (40 ~ 20 000) Hz

Signal-to-noise ratio 75 dB

Dynamic range 80 dB

• SPEAKERS

Front Speaker Sub Woofer

Type 2 Way 2 Speaker 1 Way 1 Speaker

Impedance 4 Ω 3 Ω

Rated Input Power 110 W 150 W

Max. Input Power 220 W 300 W

Net Dimensions (W x H x D) 232 x 346 x 289 mm 250 x 346 x 356 mm

Net Weight 3.3 kg 5.5 kg

Designs and specifications are subject to change without prior notice](https://image.slidesharecdn.com/lg-rat375b-141222222237-conversion-gate02/85/LG-RAT375B-9-320.jpg)

![3-19

BLOCK DIAGRAMS

1. MAIN BLOCK DIAGRAM

P/UP

M

A,B,C,D,E,F

PD

LD

CD_DIN_DOUT

CD_MCK/CD_R/W

BUSY;CD-16M SUBSYQ;

9543-RST;

VFD

AMP

TAS5612

DMA[0..11],DB[0..15

]

DSCK#,CKE,CS0#,RAS0

#

TDO

SLDO

SPDO

FDO

12MHZ

16.93MHZ

POWER

I/F

3.7V

12V

DAT, CLK, RST, CE, INT

RST, WEN#,CE#

A[0.. 18], DB[0..15]

OP/CL

OP/CLLI

MIT

CD-BCK/LRCK/DOUTA

DAC-MCLK

P-SENSE

PWM

PS9850

DO

STB

CLK

ADC-CLK

ADC-DAT

ADC-RST

ADC-DATA

R/L

R/L

I2SCLK

DAC-BCK/LRCK/MCLK

DAC-DATA

PWM-RST

PWM-CLK

PWM-DAT

PDN

SD; OTW

FL+

FL-

FR+

FR-

D+/-

P-CTRL

R

L

DAT

CLK

SPI-DO/DI/CLK/CS

RMCKEY

9.8304MH

Z

32.766khz

NewPWM

SWSW+

SW-](https://image.slidesharecdn.com/lg-rat375b-141222222237-conversion-gate02/85/LG-RAT375B-34-320.jpg)