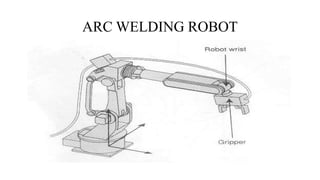

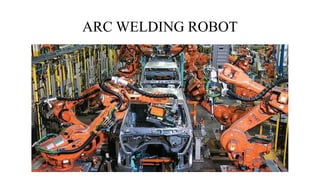

This document discusses arc welding robots. It describes how arc welding robots work by using an arc welding gun to transmit welding current from a welding machine power source to an electrode. Welding fixtures and workpiece manipulators are used to precisely position parts for welding by the robot. Arc welding robots provide benefits like improved safety, quality, and productivity over manual welding. However, variations in part dimensions and edges can present challenges. In conclusion, arc welding robots can help relieve humans from hazardous and repetitive welding work.