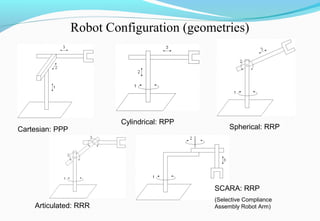

Industrial robots are essential to modern manufacturing. The first modern robots, called Unimates, were developed in the late 1950s and early 1960s by George Devol and Joe Engelberger. Since then, robots have advanced through four generations and are now reprogrammable, multifunctional manipulators used to transfer materials, parts, tools, and devices through variable programmed motions. Common robot components include arms, end effectors like grippers or tools, drive mechanisms, controllers, and sensors. Robots are useful for applications like material handling, machine loading/unloading, welding, assembly, and inspection. While robots provide advantages like increased output and consistency, they still have limitations and rely on human creativity, decision making