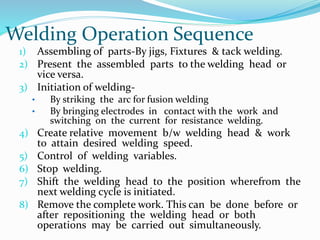

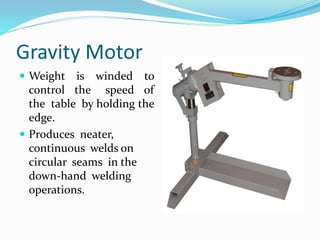

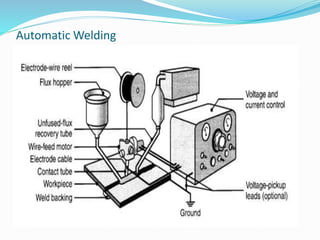

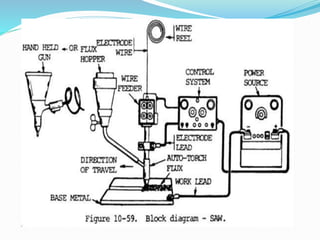

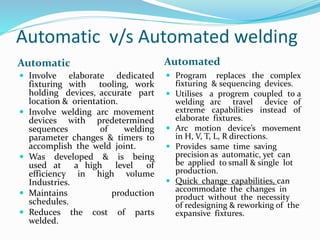

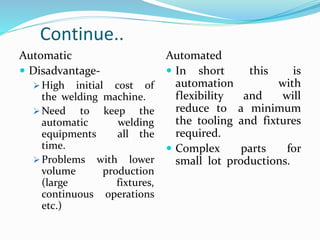

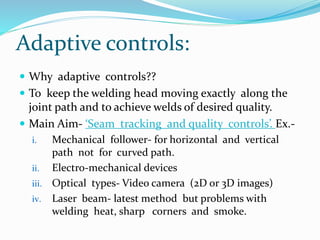

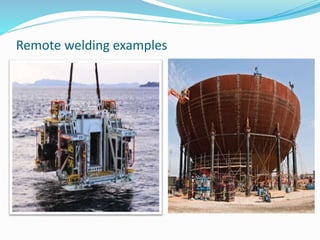

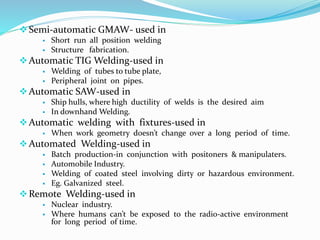

The document discusses various types of automation in welding processes including manual, semi-automatic, automatic, automated, remote, and robotic welding. It describes the key stages in a welding operation sequence and provides examples of different techniques used for automation in welding applications from the 1920s to present day. Specific automation techniques are highlighted for different welding processes based on factors like production volume and part geometry.