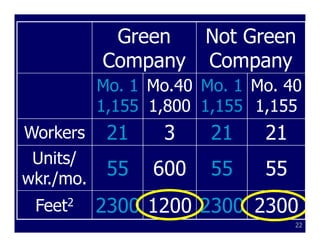

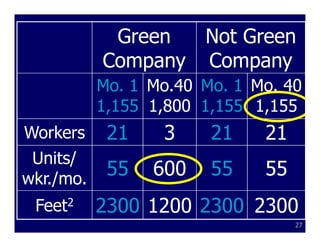

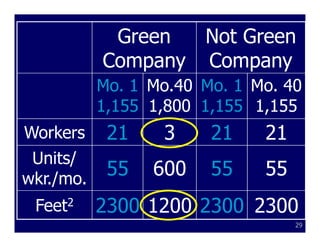

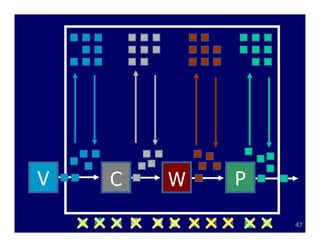

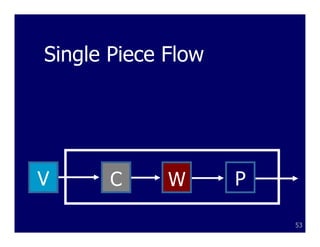

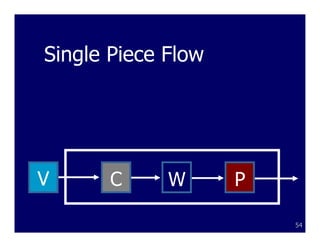

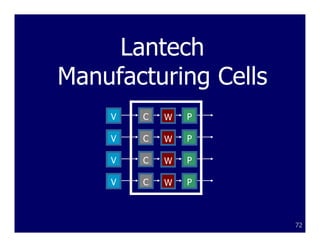

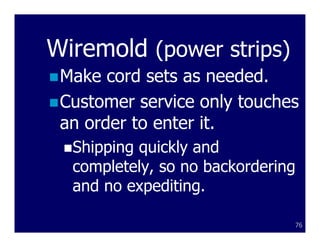

The document discusses how lean manufacturing can lead to a lower carbon footprint by reducing waste and emissions in industrial processes. It highlights the transition from traditional manufacturing practices to more sustainable approaches, illustrating this with examples from companies like Lantech and Wiremold. Ultimately, it emphasizes that lean strategies not only improve profitability but also contribute to environmental sustainability.