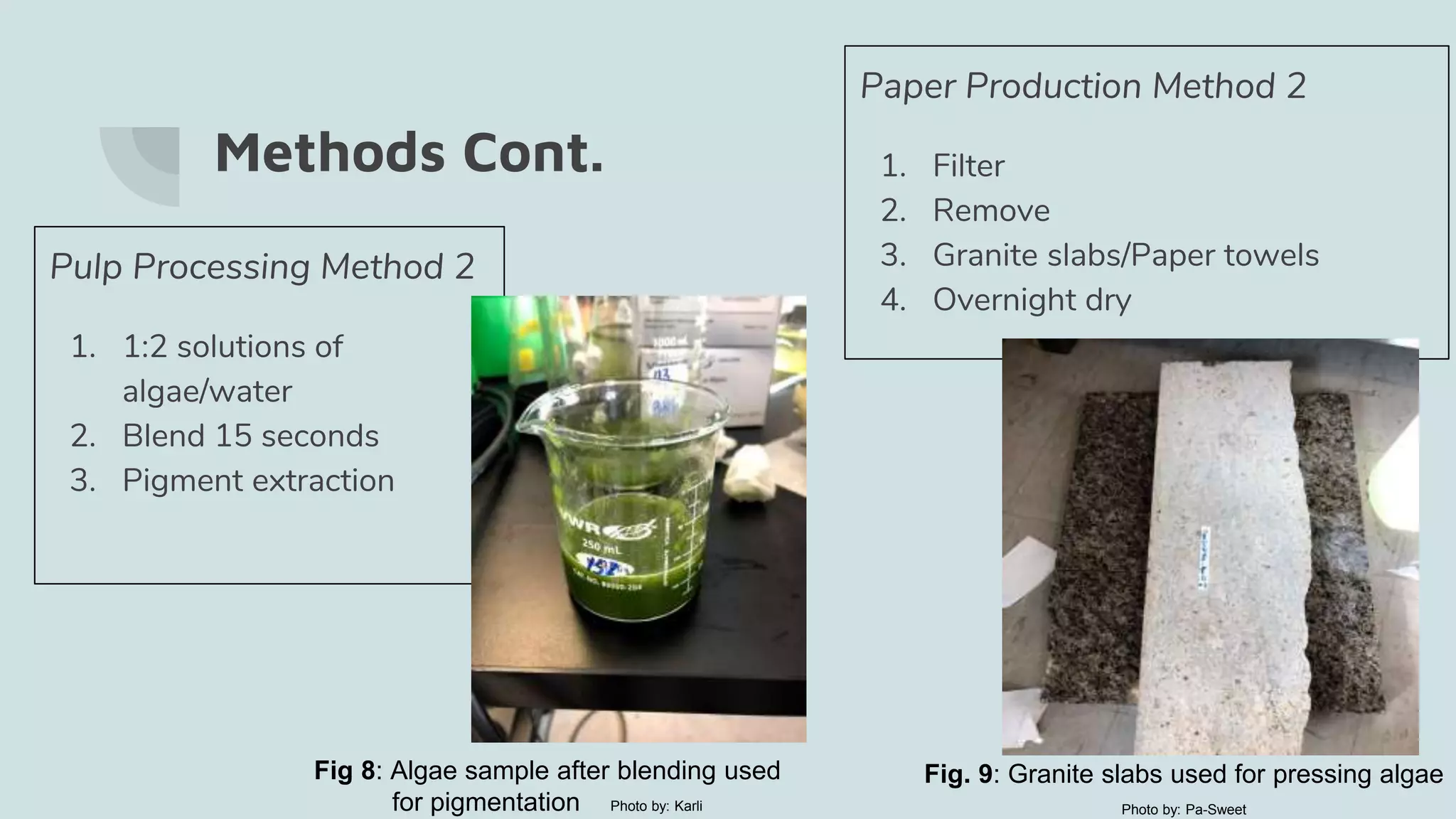

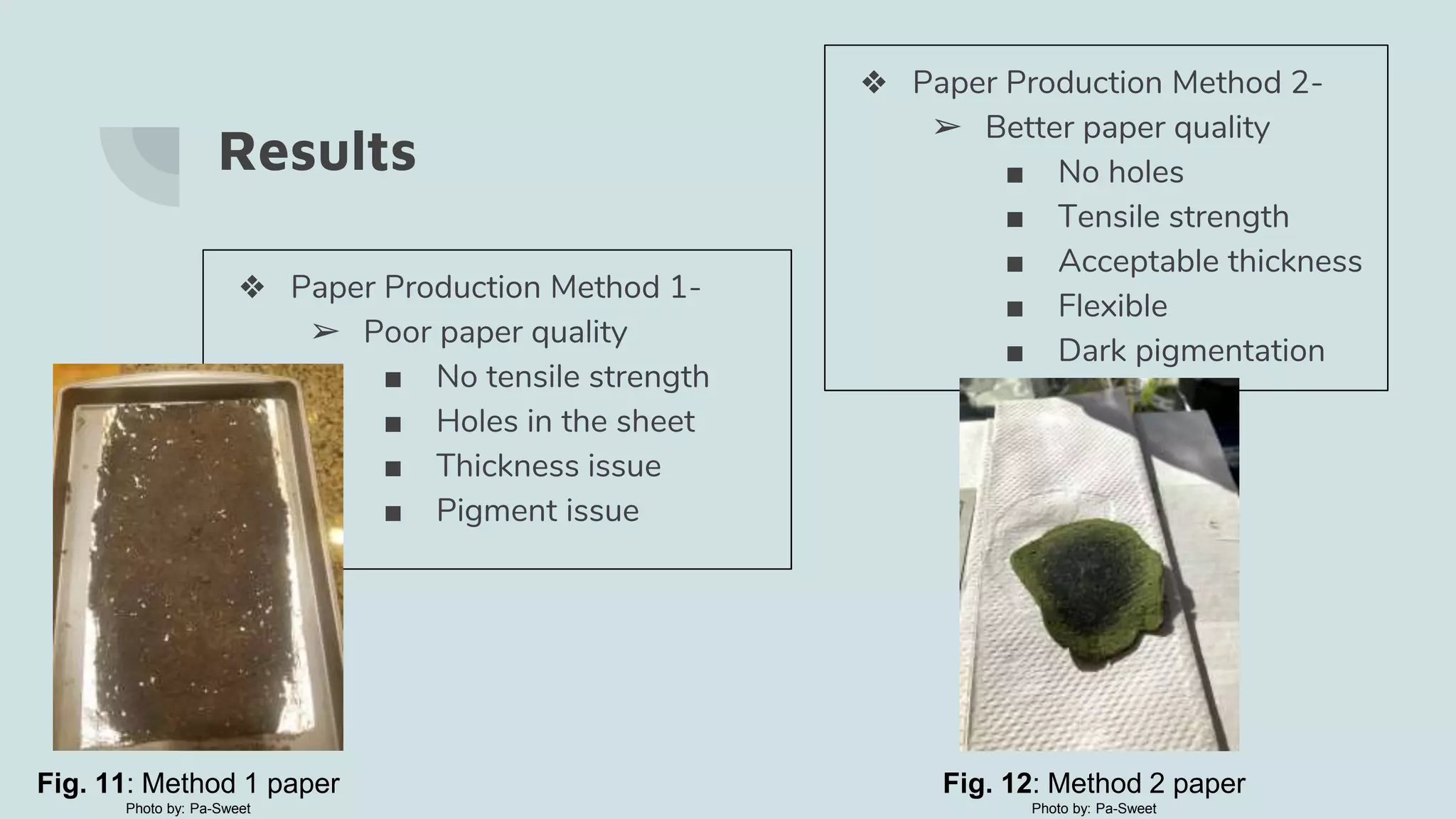

This document summarizes a student project that aimed to produce paper and pigments from algae. The goals were to harvest 25 kg of algae per day and extract pigments. Two methods for processing the algae into paper were tested: method 1 included bleaching with hydrogen peroxide while method 2 did not include bleaching. Pigments were successfully extracted from various materials including algae, but the paper quality was better without bleaching. Further research is needed to improve the paper making process and increase the quality and usability of the final product.