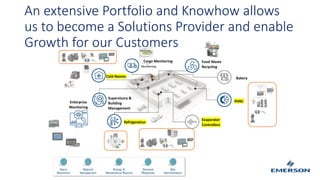

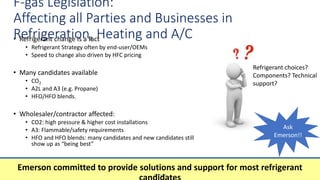

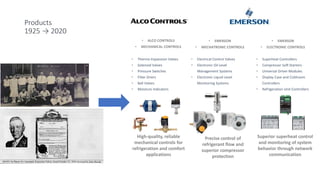

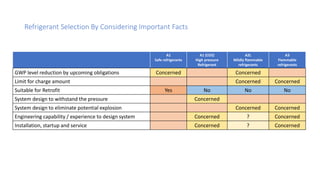

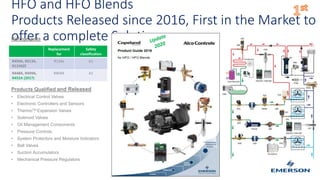

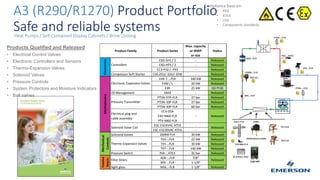

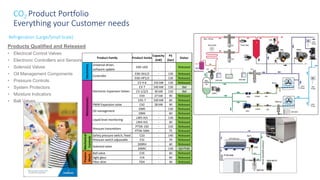

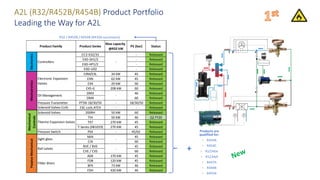

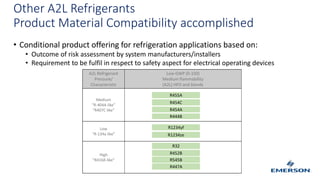

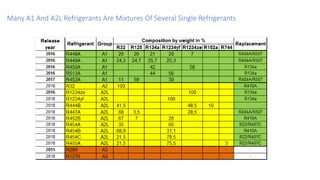

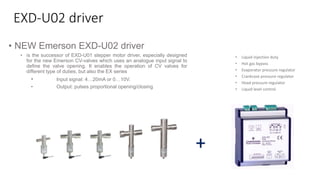

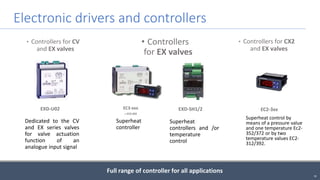

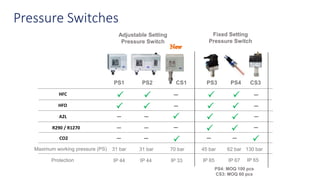

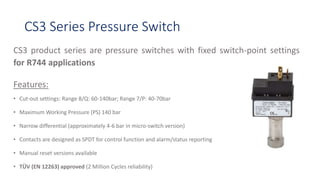

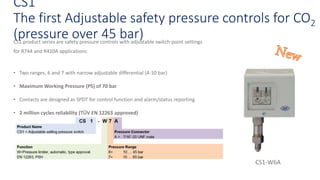

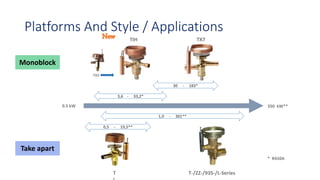

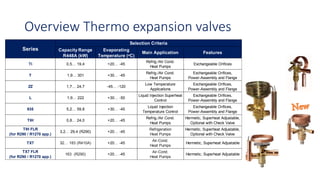

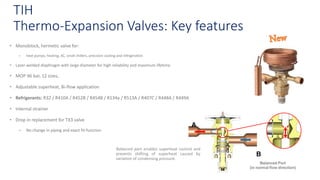

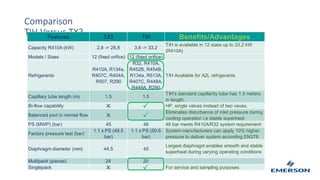

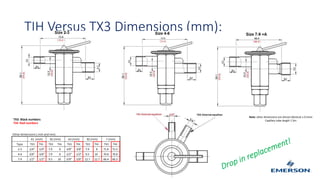

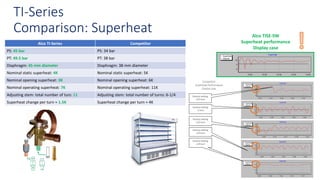

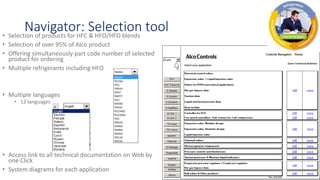

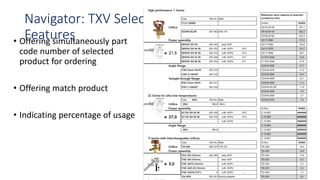

Alco Controls presented an overview of their refrigeration product portfolio and strategy for new refrigerants. They offer a wide range of products including electric control valves, electronic controllers, thermo-expansion valves, solenoid valves, and pressure controls that are qualified for HFO/HFO blends, CO2, A3, and A2L refrigerants. Their goal is to provide customers with solutions to help them transition to new refrigerants that are compliant with F-gas regulations.