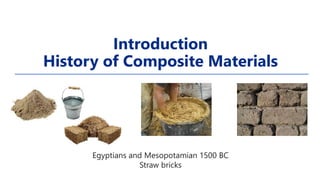

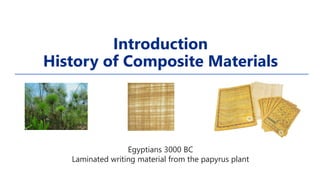

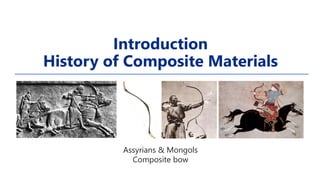

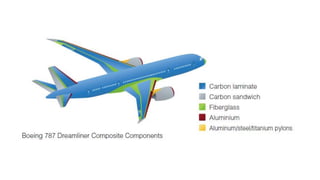

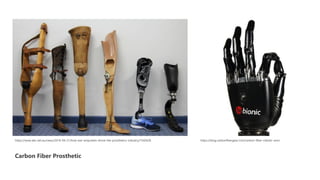

The document discusses the history and applications of composite materials across various industries, including aerospace, automotive, bioengineering, chemical engineering, construction, electrical engineering, marine engineering, and sports. It highlights the advantages of composites, such as strength, lightweight properties, and versatility, as demonstrated by examples like carbon fiber in aircraft and prosthetics. The document underscores how composites have evolved to meet industry demands for performance, safety, and sustainability.