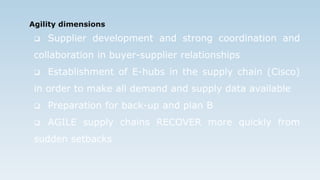

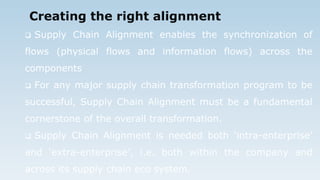

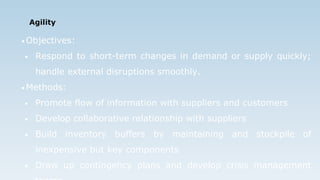

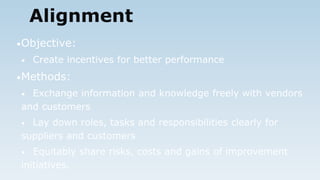

The document discusses the challenges and importance of agility in supply chain management, highlighting issues such as lack of coordination in logistics and marketing, as well as the need for adaptability to unpredictable events. Key dimensions of agility include strong supplier relationships, information sharing, and the ability to quickly adjust to market changes. Companies are encouraged to develop collaborative strategies, maintain small inventories for bottlenecks, and create contingency plans to enhance their supply chain resilience.