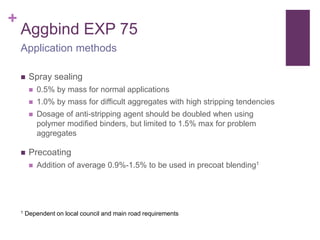

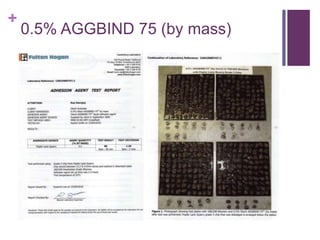

The document introduces Aggbind, a bitumen adhesive agent produced by Otech Australia that provides optimum adhesion for road sealing and prevents issues like potholes and stripping. It discusses the technical advantages of Aggbind over other products, provides specifications and test results, and presents Aggbind as a proven solution in the market based on third party accreditation and customer testimonials. The document also provides contact information for WBF PTE LTD, the distributor of Otech road maintenance products in Asian markets.